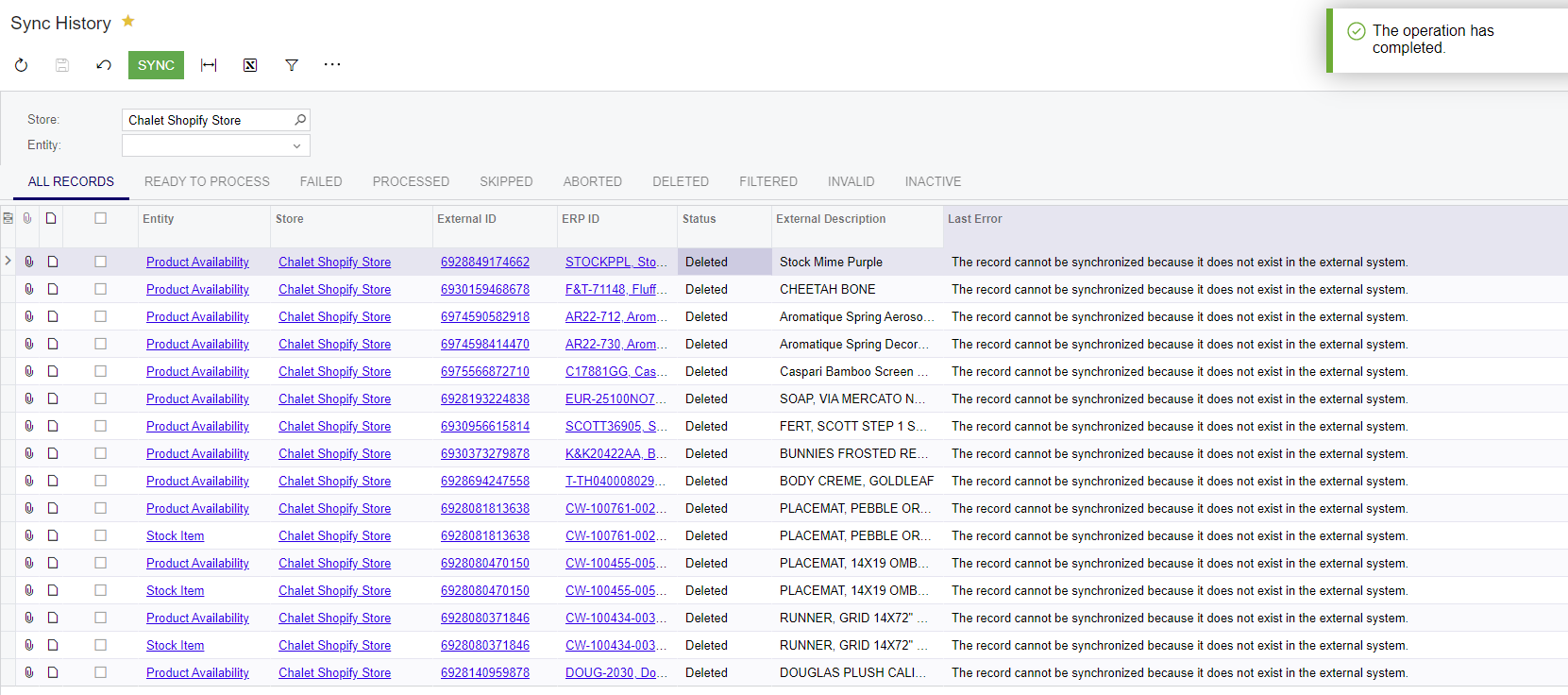

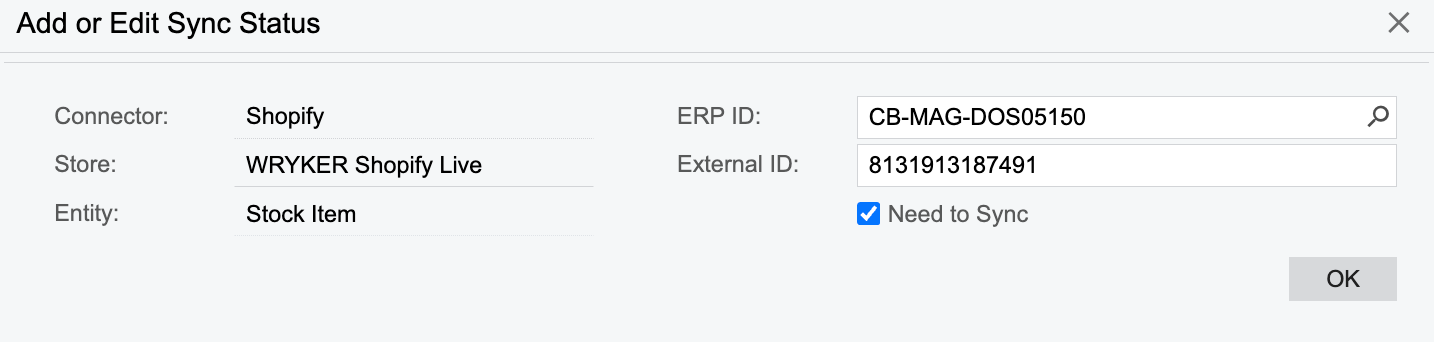

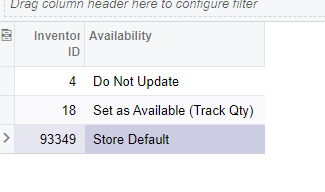

I’ve had this issue for exactly a month now. Items randomly fall into this error status of “The record cannot be synced because it does not exist in the external system”. All of these also have the characteristic of being a Status = Deleted. The item itself isn’t deleted but the Sync History record is. See this video which shows that when I try to update the status and sync the item, it automatically falls back into the status of Deleted:

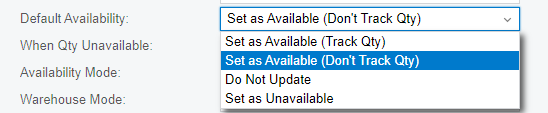

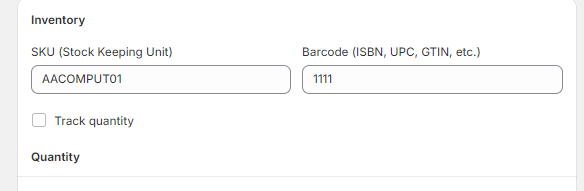

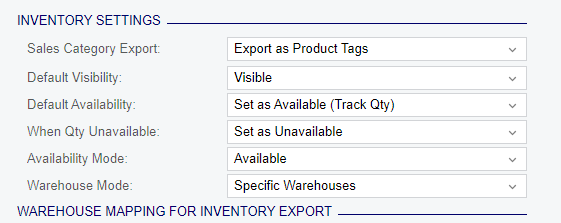

We’ve been manually updating our inventory in Shopify, among other manual updates due to bugs. It’s very labor intensive and we’re going into our busy season. We migrated to Acumatica due to the integration with Shopify, but it’s not working out so great. Please help!