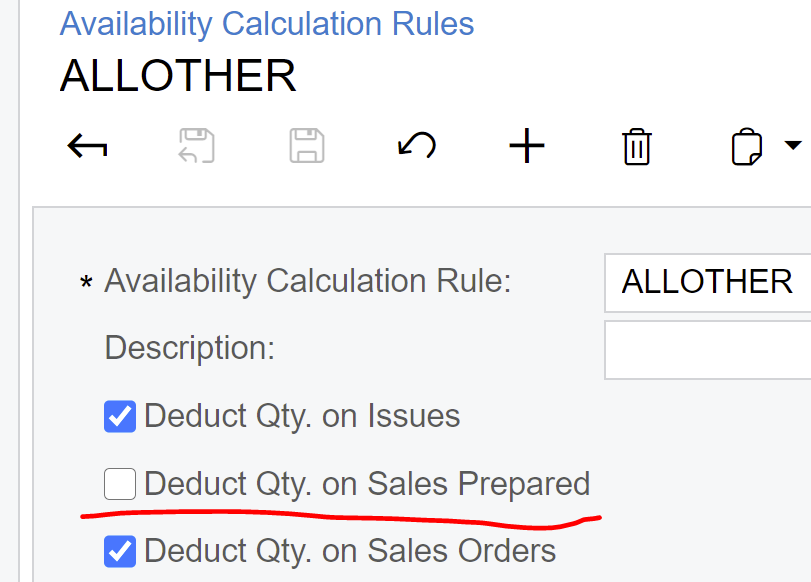

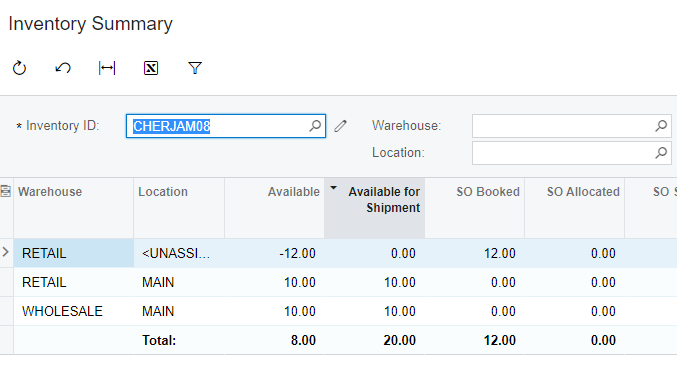

There are only 2 choices to show available for the web store. My client would prefer that negative available is ignored and factored into the calculations. In the example below, they want to see 10.

This is an example I set up and tested with the store setting for Availability Mode for Available and Available for Shipping.

- When set to Available the store shows a qty of 8

- When set to Available for Shipping it shows 20

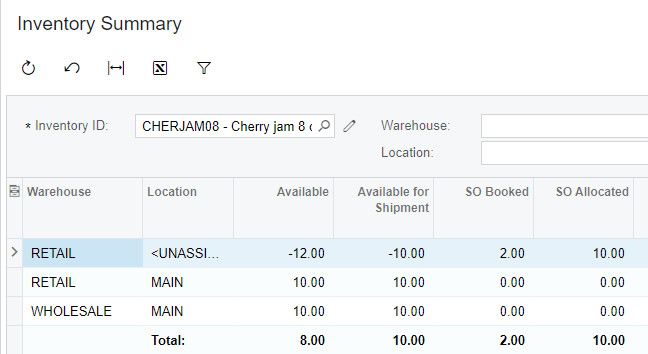

If I allocate the sales order for the 10 pieces it changes to either 8 or 10. Generally, we do not set the sales orders to allocate because it ties up inventory you could use for orders with earlier ship dates. Unfortunately, there is no way to allocate orders based on date.