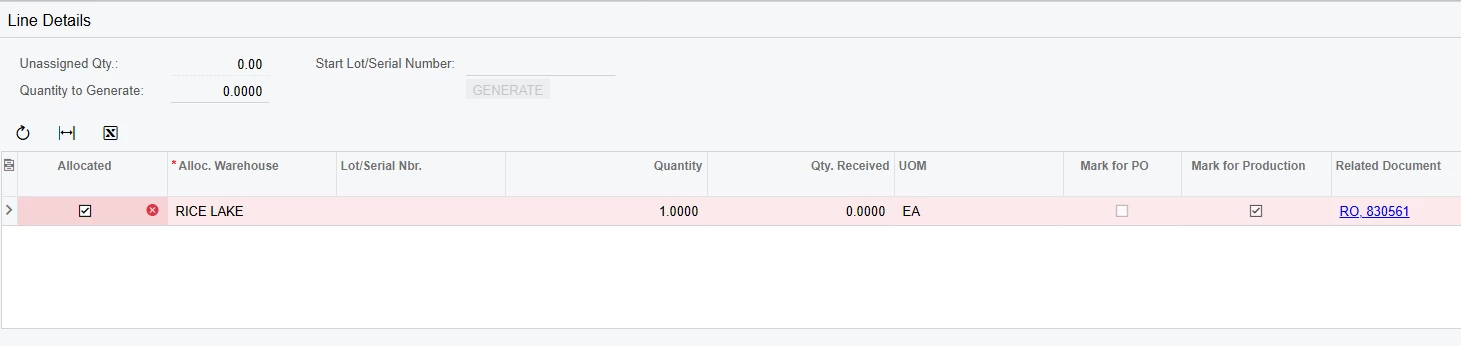

Is it possible to hard allocate a part that is listed as a material requirement and marked for production on a parent production order? When the child production order is completed, we’ve had problems with a sales order getting shipped when the part was needed for the production order first (hence the link production order).

If we have a 3 production orders for 3 machines and each one requires part 123 so we create the production orders that will then be linked to parent machine jobs. We can also sell part 123 on sales orders too, so when a production order that is linked to a parent order is moved into inventory, why does does Acumatica allow a shipment for the part that was made and linked to a machine production order?