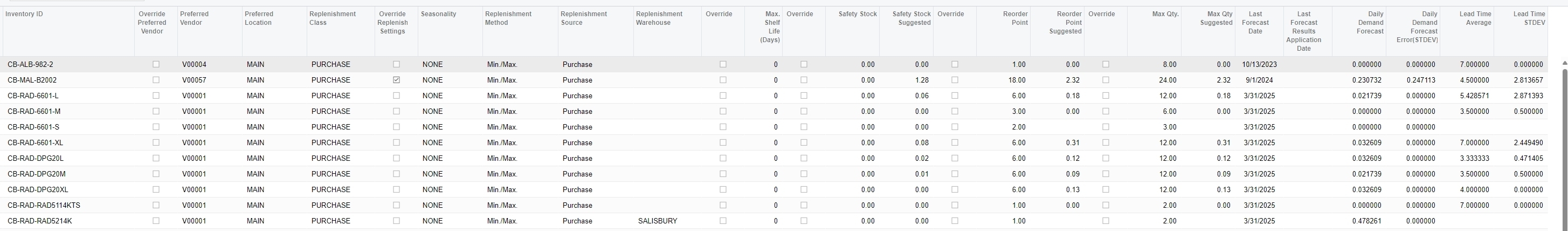

I am trying to setup and use the Calculate replenishment part of our system. I run the calculations, and they do not appear to be correct. I have an item that I sell 10-12 per week. And the lead is 5.22 days. The system is calculating my Safety Stock at 1.09 and the reorder point at 2.91 and max suggested at 2.91. At this rate I would always be ordering for every order that I get. I would always be out of stock. I have read the help menu to try and understand why these calculations are off, and I am thinking it has something to do with the number of days I am trying to stock for. But I do not know where my setup is incorrect. Is there a good tutorial on how to set this part of the system up? And how to setup the Replenishment parameters.

Thank you,

Kevin