Problem:

When a production order is created for a configured item, the “Mark for PO” box does not get checked on production materials that have the “Dflt. Mark For” value set to “Purchase” on the inventory item record. This means that no purchase demand will show up on the “Create Purchase Orders” screen and the purchasing manager will not be aware of any custom order materials that are required until production employees are ready to perform the operation and discover that materials have not been ordered.

Affected Versions:

2024R2 (all builds, as far as I am aware)

Simple Workaround:

Immediately upon learning of this problem, I created a Generic Inquiry to enable a user to easily view affected records. This displays Production Material lines where Mark For PO is false, but the Dflt Mark For value on the inventory item is Purchase. This is great, but potentially a lot of work, since it has to be reviewed regularly and requires a manual correction.

I’ve attached the GI below, in case any other manufacturers are dealing with this.

Automated Workaround:

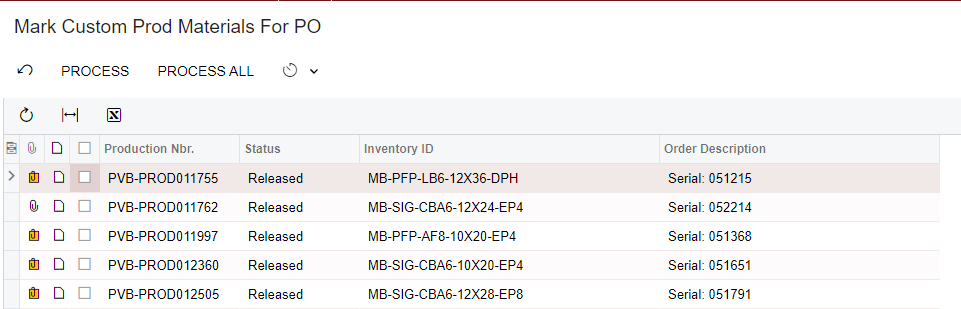

Since we don’t know how soon this will be fixed, I then created a custom processing screen that displays all production orders with a Released status (we don’t order custom materials until the production order has been released) that have custom order materials in them that do not have the “Mark For PO” box checked. I put this on an automated schedule to run every few hours. It puts affected orders on hold, checks the Mark For PO box for all custom materials, and removes the order from hold again. Now purchase demand is generated and the purchasing manager can order custom materials as usual.

Let me know if you need help implementing the automated workaround.

CONSIDERATION: I don’t know how it’s intended to work, but it seems that when a production order configuration is unfinished and refinished, the item plans are recreated. This means that if the process has run and checked the box, the purchasing manager has created a purchase order, and the configuration is unfinished and refinished. Then the process will check the box again since the production BOM was re-built, and new purchase demand will now be generated. This means that in some edge cases, you could get duplicated purchase demand for custom materials. Since this is a temporary bug, I didn’t try to dig deep into item plans to figure out how to track changes in demand across revisions.

Hope this helps,