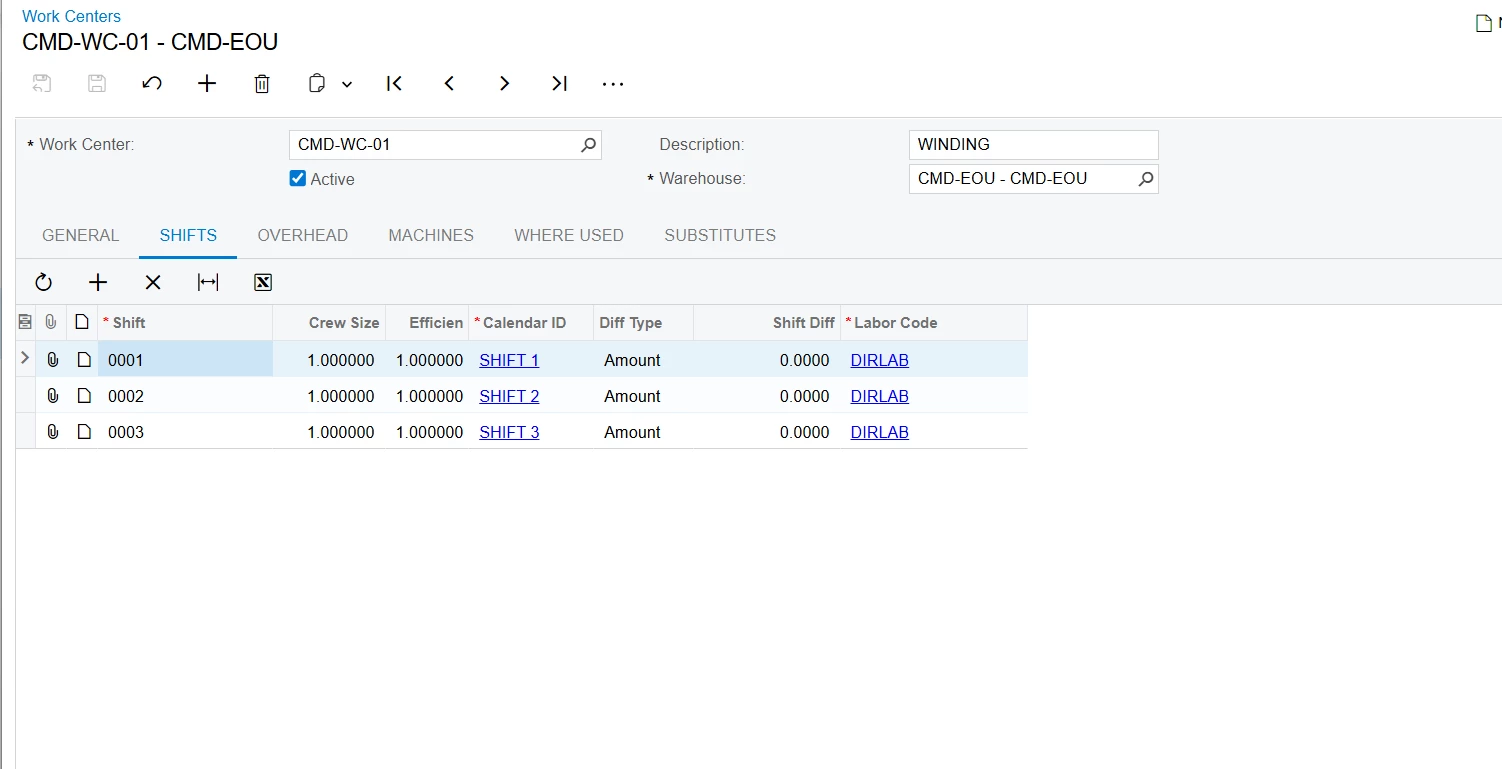

We have a problem in configuring work center. A work center is configured with ‘basis of capacity’ set to crew size, and three shifts are added, each with a different calendar. The calendars are configured with 8 working hours in a day, but the timings are different.

When the MRP runs, the action date calculates based on the crew size and calendar in the first row of shifts but we thought it would consider all the shifts. If all the shifts are considered, the action lead time should be reduced to one-third, as the total working hours of the work center are 24 hours.

We are not sure why Acumatica considers only the shift details in the first row