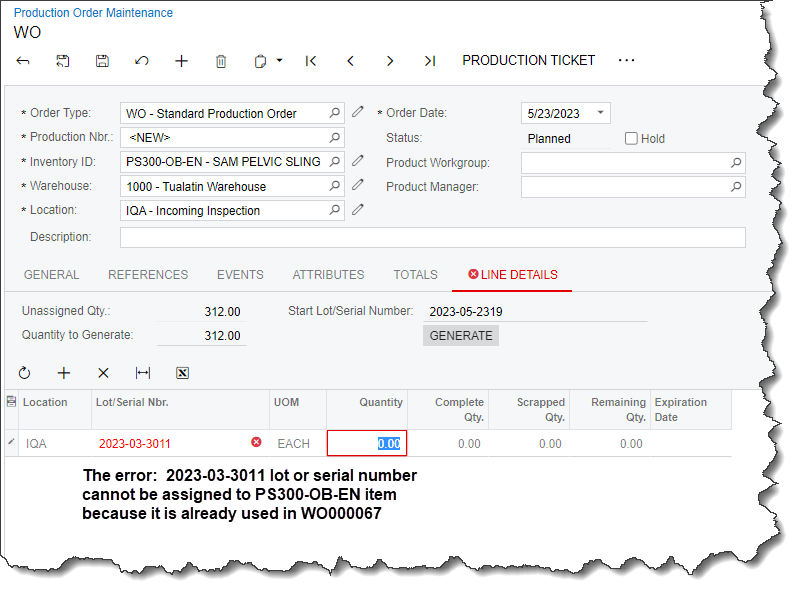

Is there a setting to allow using the same lot number for an item for multiple production orders? I have a client that tracks the lot number of the component. They usually create several orders to consume the component, but can’t use the same lot number across multiple production orders.

Solved

Reuse lot number in Production Orders

Best answer by Debbie Baldwin

If they don’t pre-assign - there is nothing stopping them from producing the same Lot Number on multiple production orders.

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.