Hello!

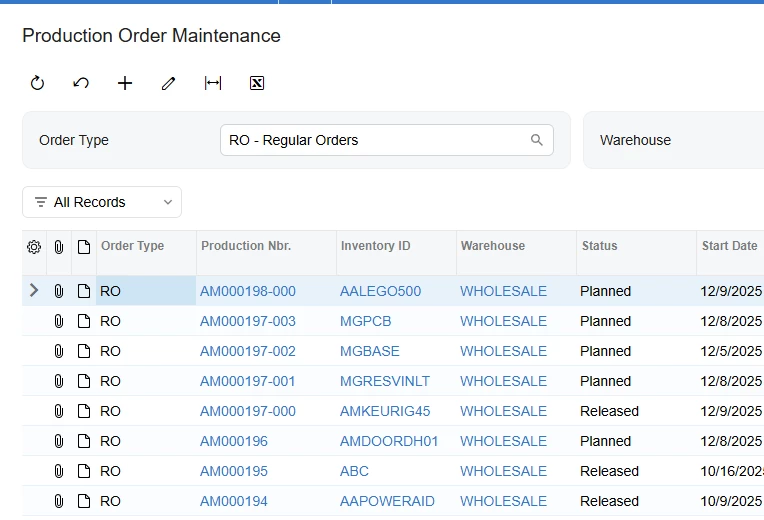

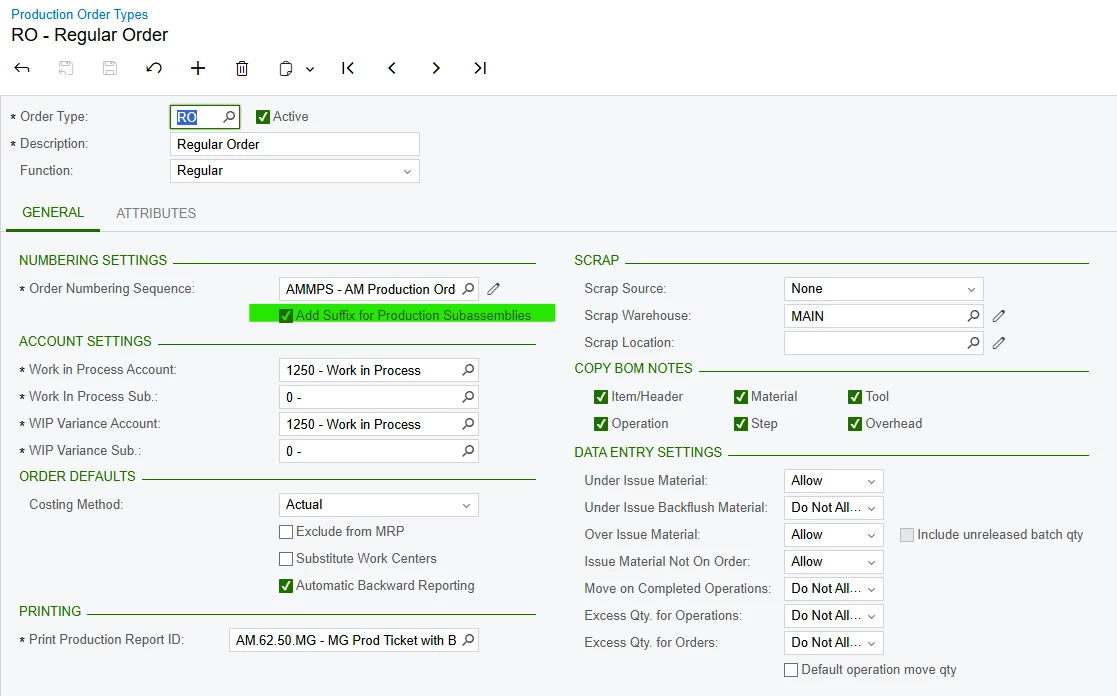

I was wondering if anyone had this issue when using this setting on the Production Order Types screen.

I turned this on to better track our subassemblies so everything can be categorized under the parent production order #. But what’s weird is that it causes the Production Order # to skip a bunch of iterations, seemingly at random.

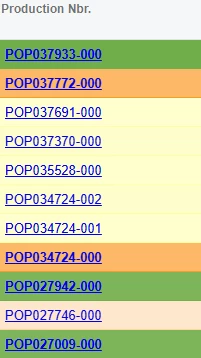

See below for a screenshot. These were all Production Orders that were created within the last ~5 days. And I am certain that there is no way that someone created around 7000 Production Orders only to delete them in that timeframe.

For some reason it jumps from POP027009-000 → POP027746-000 all the way to the most recent which is POP037933-000. And in this screenshot, the earliest production order (POP027009-000) to the most recent (POP037933-000) jumps over 10,000 iterations. Prior to turning this setting on the numbering sequence worked as intended.

Is there something conflicting between this setting and the numbering sequence?

Does anyone know why this is happening and is anyone experiencing a similar issue?

Thank you!