Hey everyone, I have looked at all of the online help regarding planning buckets and I still don’t have a good grasp as to what a planning bucket actually is and how I should set them up. Can anyone help further explain what they are for? Thanks!

Planning Bucket Help

Best answer by andrewm

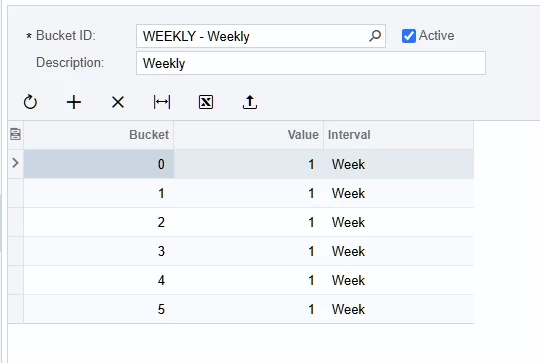

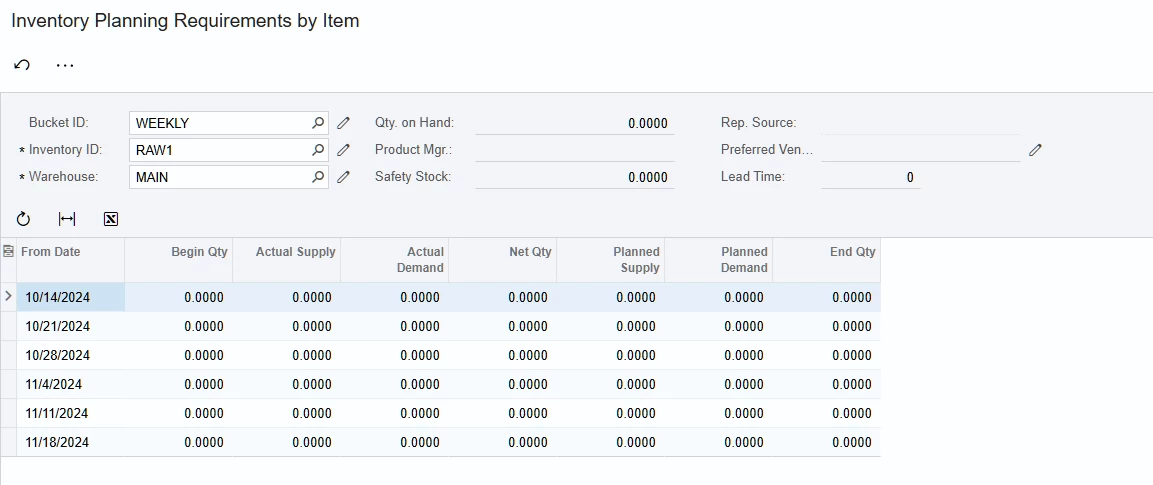

Planning Buckets are to be used along with Inventory Planning Requirements by Item. Here is an example of a Bucket type for “Weekly” along with how it displays via Inventory Planning Requirements by Item.

You will notice that Bucket 0 actually looks one week or interval backwards for anything that is “past due”. You can continue to look backwards by adding additional buckets like -1, -2, -3, -4 etc… Bucket 1 is this week, Bucket 2 is next week etc. One important thing to note is that if you want to see Past Due values, Acumatica will only show you the value if you have a bucket created. For example, today is 10/21/2024. If I had something past due in September and I am looking 2 weeks back, it does not appear.

The “Value” here is always 1 because I am incrementing by 1 week each bucket. If I specified 2 or 3 here then it would actually jump 2 or 3 weeks when running Inventory Planning Requirements by Item. You can easily mess around with your Buckets/Values and re-run the report to see how it changes.

The interval can also be changed to Days, Weeks, Months or Years. I typically just make a Bucket ID for Weekly, Monthly, and Daily. Depends how far in advance the user needs to plan. You may want to create a handful of different Bucket ID’s, i.e 14 days, 7 days, 6 weeks, 12 weeks, 3 months etc.

As for what Inventory Planning Requirements by Item is telling you: you start at the top left and go left to right, then down one row. Beginning Quantity + Actual Supply - Actual Demand = Net Quantity. Actual Supply and Actual Demand are Jobs, Sales Orders, Purchase Orders etc that have been created.

Then you have Net Quantity - Planned Supply - Planned Demand = End Quantity. The “Planned Supply” here are the “Requirement Plans” that Acumatica suggests when you run Inventory Planning Display. For example, if you are short and need to purchase 100 lbs, Acumatica creates a “Requirement Plan” for 100 lbs. The Planned Demand comes from Forecasts and things like “planning orders” that create additional material demand.

I am a fan of looking at MRP this way as well as using “consolidations”. It gives you a more broad view of the planning requirements for that item over some time frame. You can also drill into the Results by Item from this screen (…) if you want to see the details of your supply and demand.

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.