We run manufacturing operations at multiple warehouses. We use the same BOMs at all warehouses because the same materials are consumed.

However, due to much higher manufacturing volume at our main facility, there are materials that are stocked at that warehouse, but are custom order at the lowest volume facility.

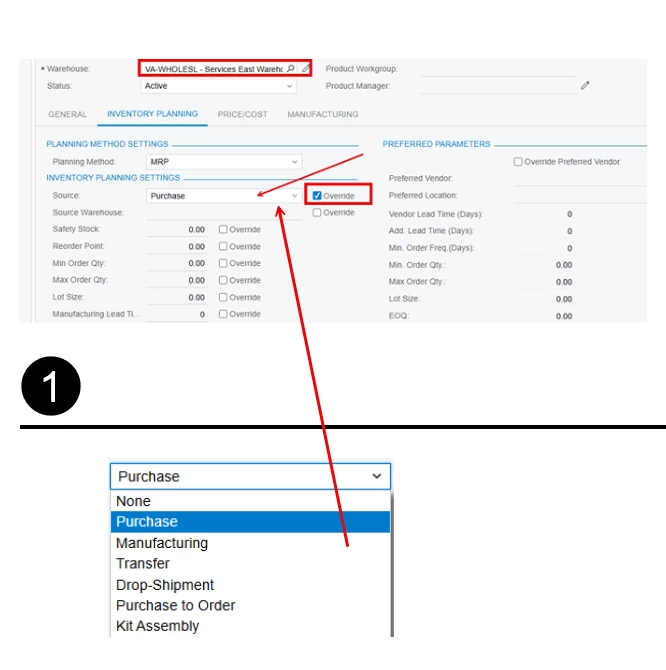

Acumatica has the “Dflt. Mark For” checkbox on the stock item level which, when the “Purchase” option is selected for an item, then system will suggest a purchase order when that item appears on a production order. However, I don’t see this option on the Item Warehouse Detail level, which we really need for those items that are regularly stocked at some warehouses, but only ordered on an as-needed basis at other warehouses.

Am I missing something, or is Acumatica missing this simple feature?

Solved

No Default Mark For at Item Warehouse Detail level?

Best answer by Debbie Baldwin

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.