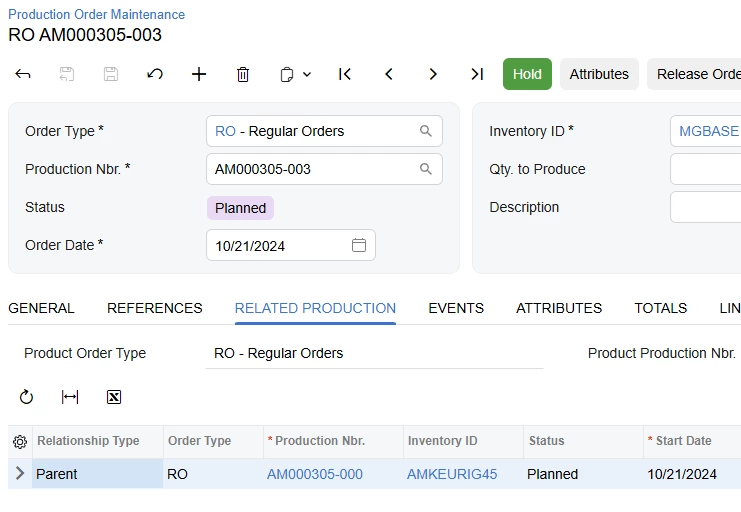

Is there any functionality in Acumatica where you can enter a production order number and a list of child production orders are display and you can select which child production orders you want to process moves/completions on?

This would be sort of like creating or printing production orders.