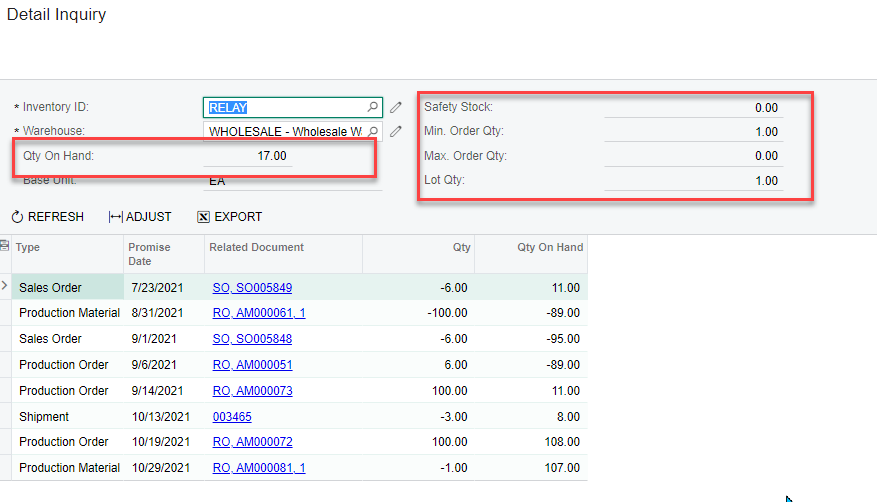

I have done some significant testing of MRP. I am unable to find a way to honor a Max Qty of an item. MRP is only suggesting orders for safety stock up to the Reorder Point. I have two clients that would really like to be able to populate both a Reorder Point (min qty) and a Max Qty for their items. Once they drop below Reorder Point, they would like a suggested order up to the Max Qty. Otherwise, as soon as you issue or sell one unit, you are back below Reorder Point and MRP suggests another purchase of 1 unit. This will lead to many additional purchase or manufacturing cycles. Inventory Replenishment handles Reorder Point (min) and Max Qty as expected.

- Is there anyway for MRP to honor a Max Quantity on its suggestions?

- How are others handling this?

Thank you,

Greg