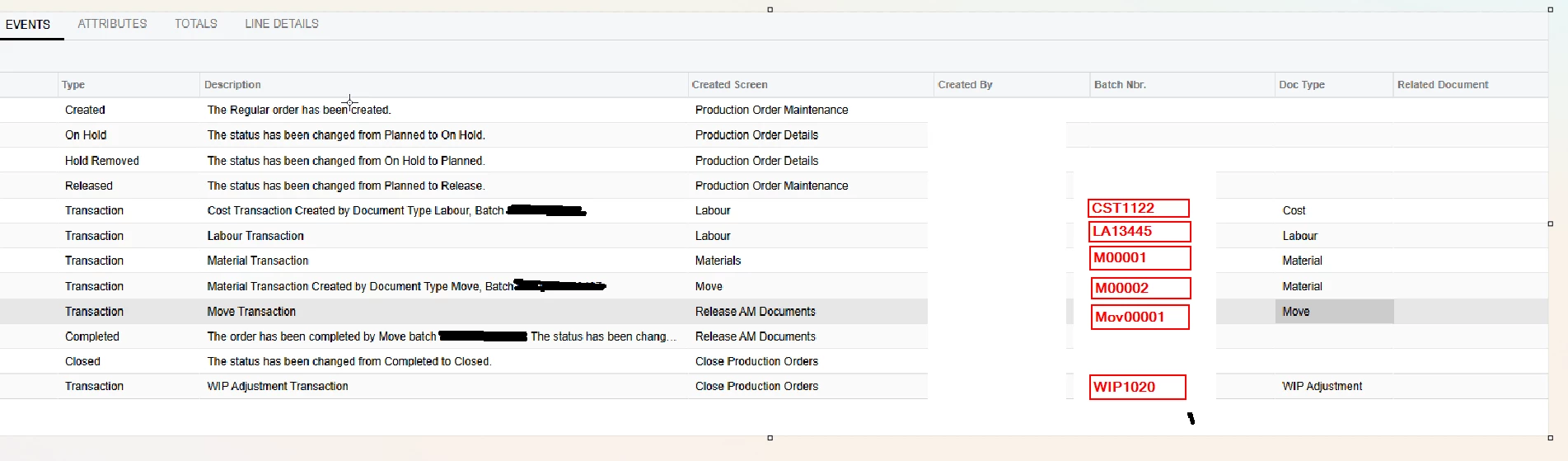

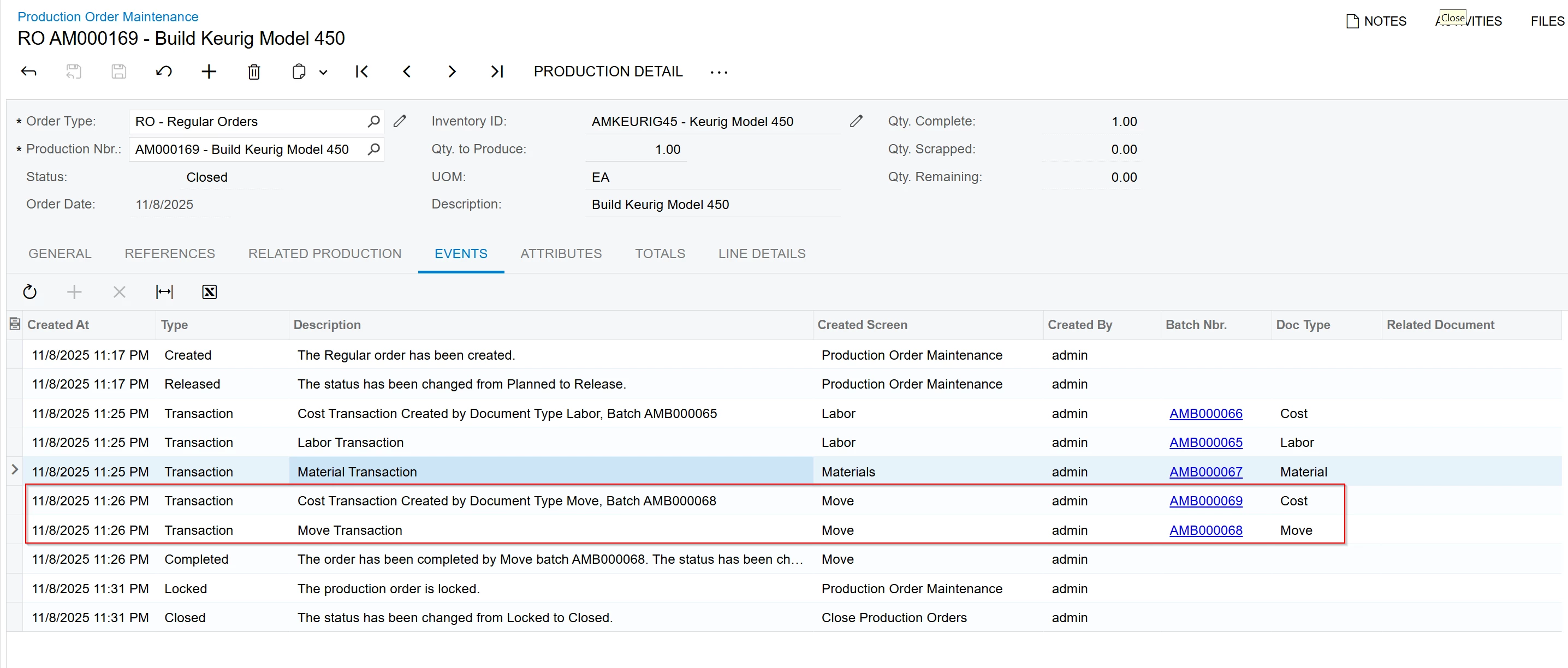

As shown in the screenshot below, we understand that when a Move transaction is performed, the system should create both:

-

The Move Transaction, and

-

The corresponding Cost Transaction.

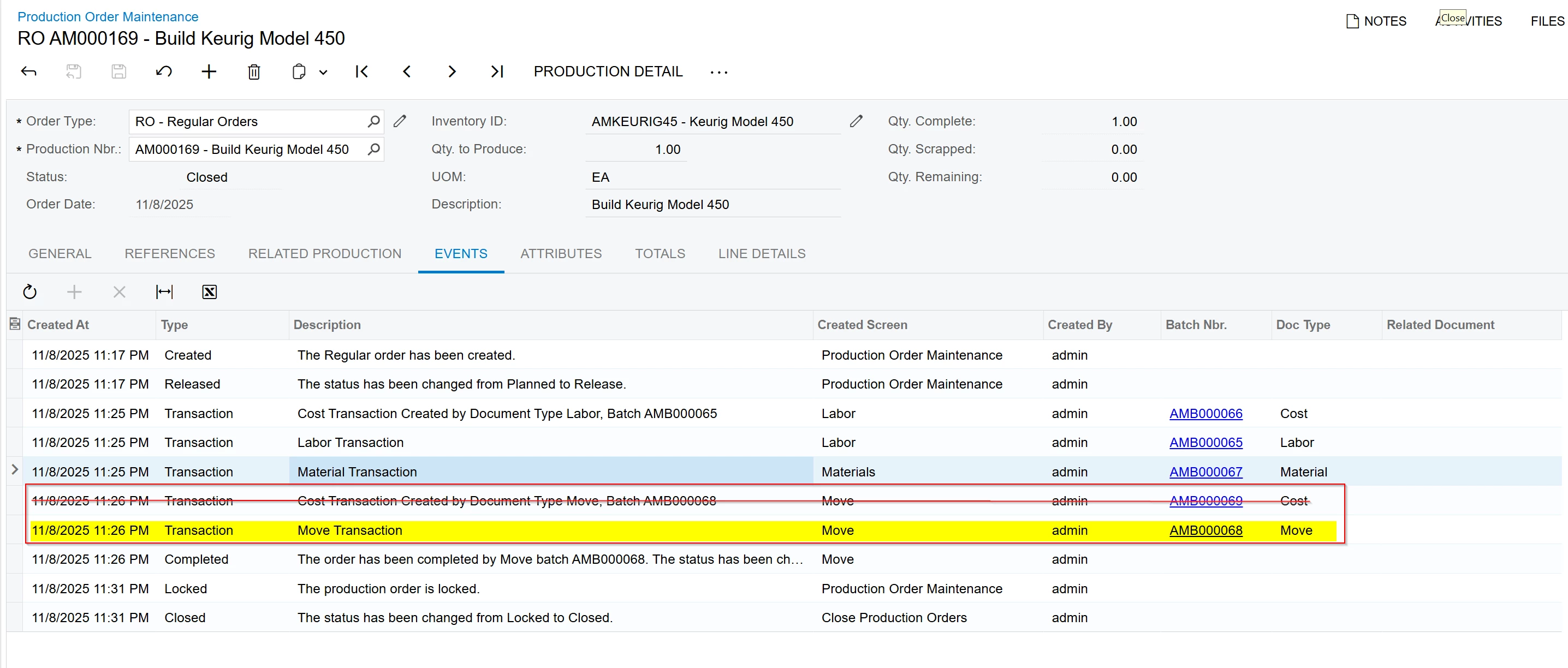

This is not the actual screenshot; it was taken from the local system. In our case, we can only see the yellow-highlighted Move transaction line. The Cost Transaction shown above does not appear in the Production Order.

We have identified an issue where, after completing a Move transaction, the Cost Transaction is not being created for that specific Move.

As a result, the system generates a WIP Adjustment Transaction when closing the Production Order instead.

We reviewed two Production Orders for the same Item Code, and confirmed that both orders have the same Event History and appear to be configured identically.

In one Production Order, the Move did generate a Cost Transaction, while in the other, it did not.

There are also no Parent Production Orders associated with these cases, and the No project Association.

We have found a few Production Orders with the same behavior, and these orders do have Projects linked to them.

Has anyone encountered this issue before?

Is there any known reason why the Cost Transaction would fail to generate when performing a Move transaction?