The purpose of the Material Requirements Planning Whitepaper is to increase your working knowledge of the MRP process within Acumatica. It is strongly recommended to first complete the M100, M200 Manufacturing Education course and be familiar with Acumatica Manufacturing processes and general MRP Configuration.

Upon the completion of the whitepaper the readers should understand:

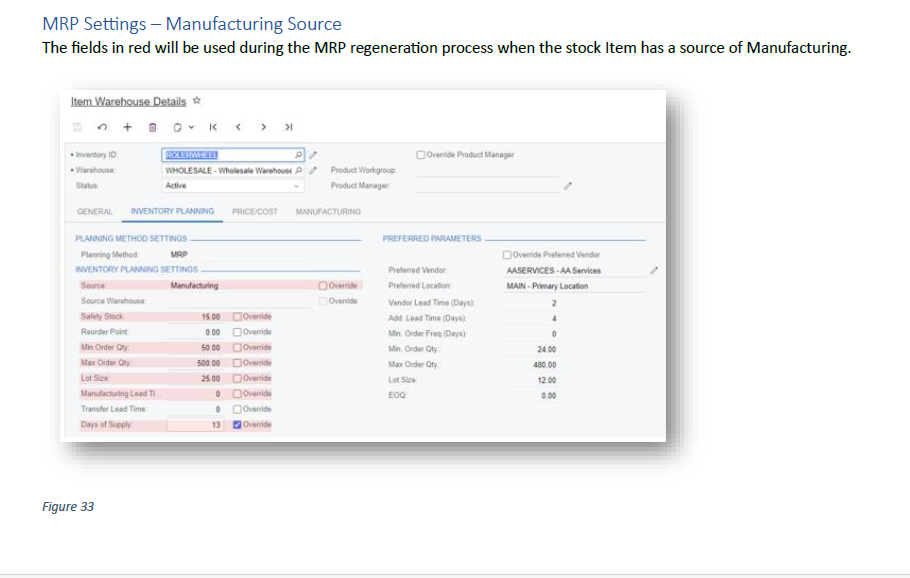

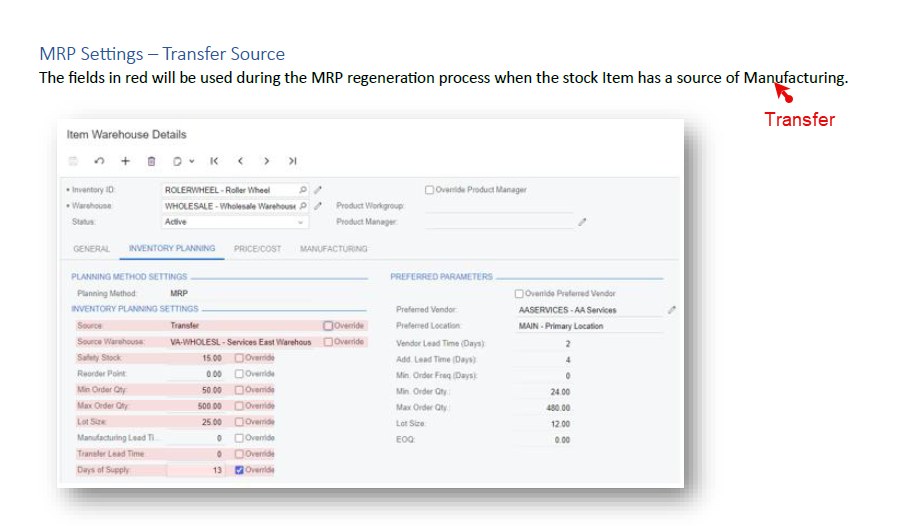

- Inputs to MRP and what parameters to consider if results are not as expected.

- How a parameter impacts planning results and where it is used in the MRP regeneration process.

- How MRP performs calculations

- The results presented by MRP by working an example backwards.

- Why exceptions are generated.

The following topics are not addressed in detail in the Whitepaper as they are well covered in the M100 and M200 Acumatica Education courses

- What is MRP

- How to configure basic MRP Preferences

The following topics are not included in this whitepaper, but may be addressed in a future:

- Forecast generation see On-line help LINK

- Dependent Forecast and Dependent MPS calculation and reduction