How do all of you juggle manufacturing and shipments?

I came from a fully warehouse background and now supporting an on-site Manufacturing facility with a warehouse attached. I am trying to optimize the existing location layout for most efficient processing without Shipping stealing from Production or vice versa.

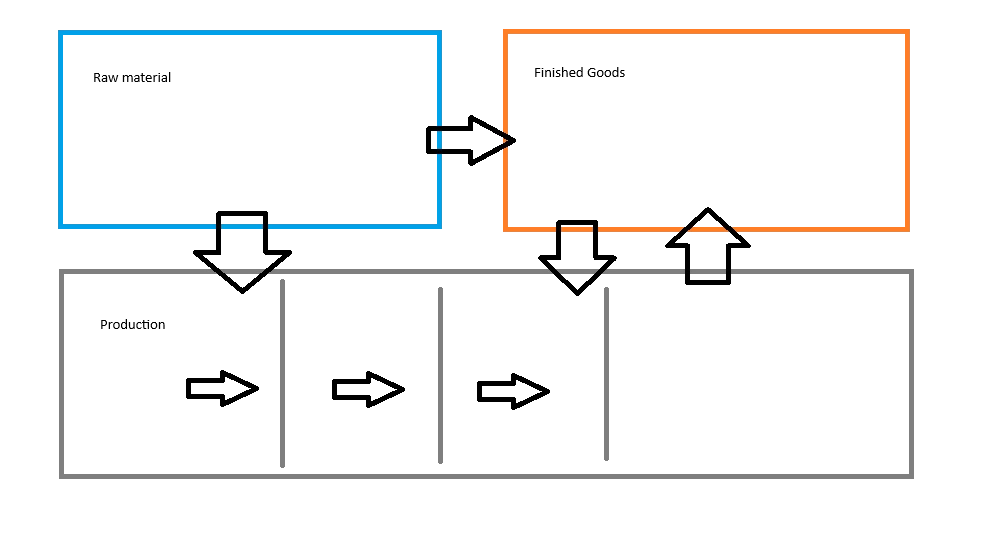

Raw material feeds to production most of the time, but could ship out.

Production has different lines that do different processes and we step through the different stages.

We also send finished goods back to Production for customization.

The site had prioritized the finished goods storage locations the first priority, which works, until we get a return or sample order less than standard case quantity. Second priority is Production drop locations for finished builds (saves time for allocation to allocate from the drop vs putting items away in finished goods storage to allocate). Picking is by a standard pack (case) quantity. If we have a partial in finished goods, it would pick the partial, and then pick the rest from the production drop.

I had changed the priority to production drop first, then get the remainder from finished goods, but that broke some Production orders as Production allocated a production drop to another assembly.

I am considering making a WC1-In and WC1-Out locations where allocation can grab from the Out location for shipments, but protects the inventory needed for the work center in the In location.

I have my locations set up:

- Finished goods = Priority 1

- Production = Priority 3

- Production drops = Priority 3

- Raw Material = Priority 5

- Off site Storage = Priority 15

- Off site Manufacturer = Priority 20

I had moved Production drops to P1 and Finished goods to P2, and left the rest alone, but like I said, it broke production allocation.