Hi,

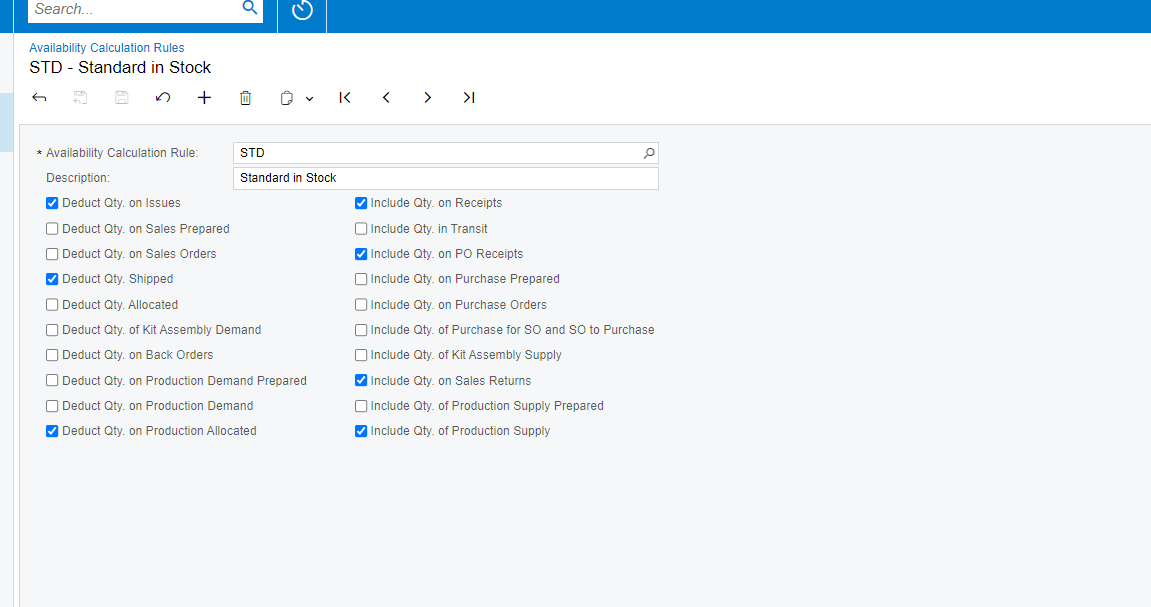

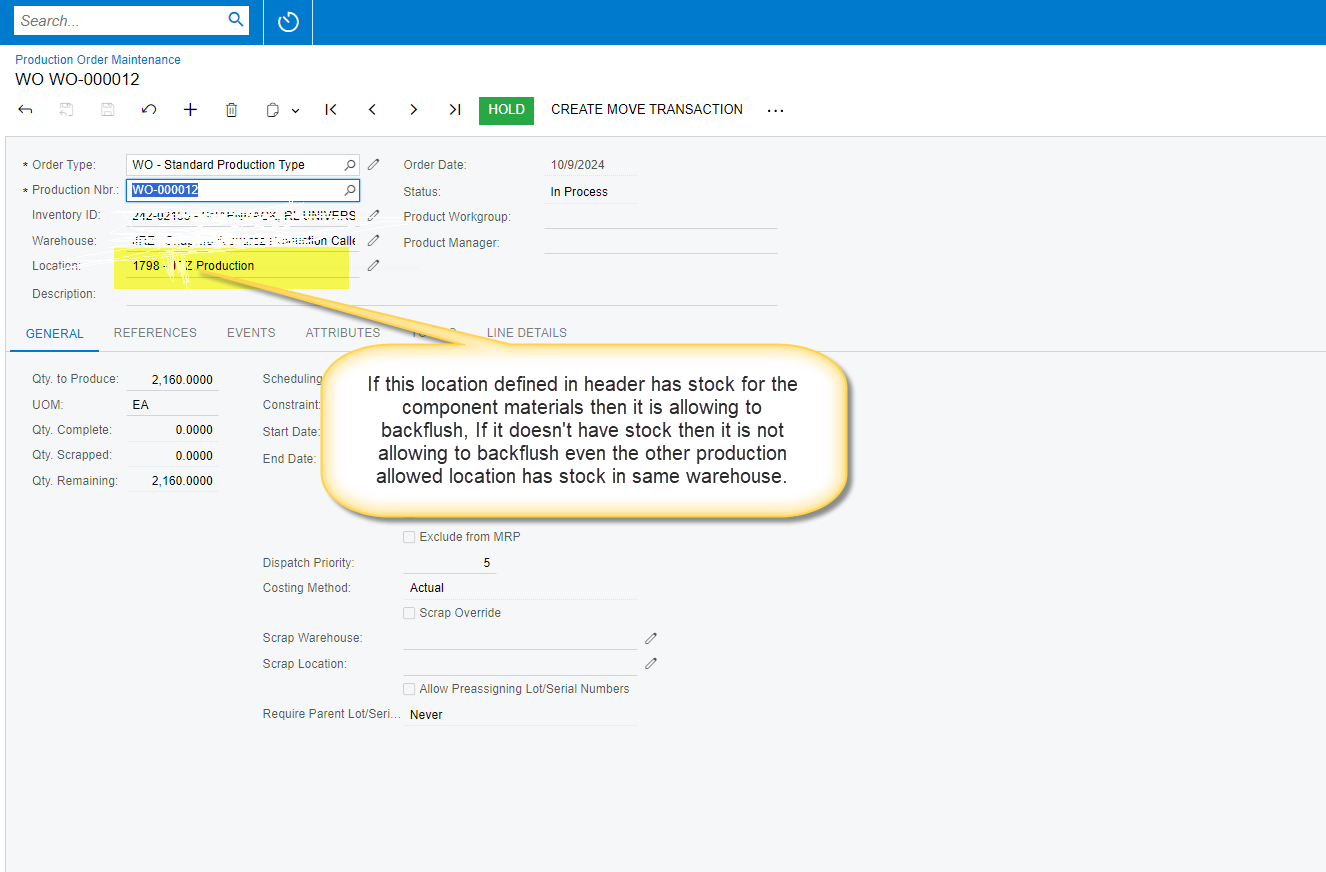

I'm encountering an issue with Manufacturing Backflush. I have a production order where all the component materials are set to backflush. The problem is that, despite having sufficient stock in the warehouse, the system is throwing an "out of stock" error during the move transaction. There’s plenty of inventory in the system, but it’s not being recognized during the move. Is there a specific logic that the system follows when selecting a location for backflushing? I’ve noticed that when there is stock in the location defined in the production header, the error doesn’t occur.

I believe the system should check all the locations within the warehouse that are set to "production allowed.