Hello,

We recently (past 3 months) went live with Acumatica and are continuing to refine our processes and explore capabilities. My current project is to set safety stock on certain raw materials so we can leverage MRP and ensure that we always maintain the necessary on hand material levels.

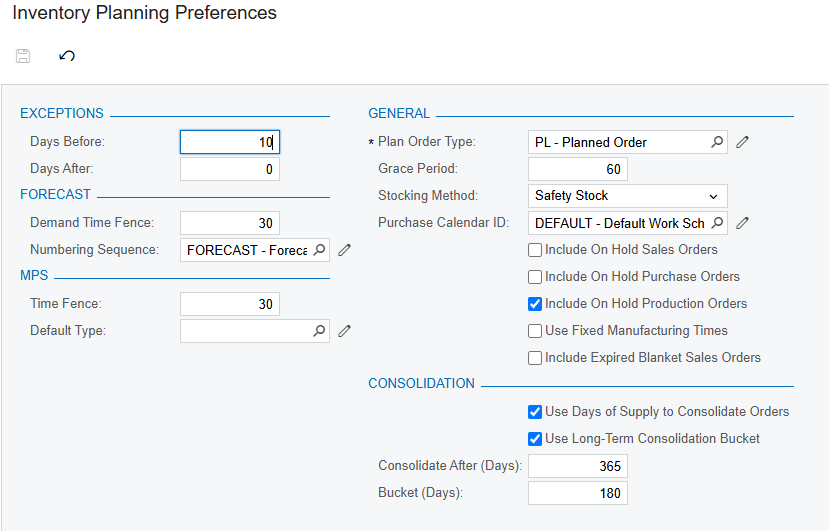

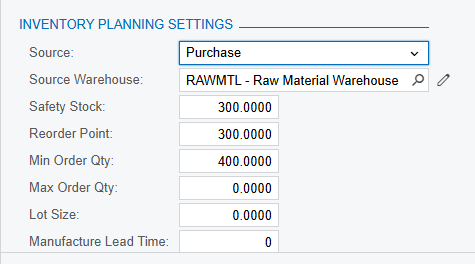

We have set our Inventory Planning preferences as shown below:

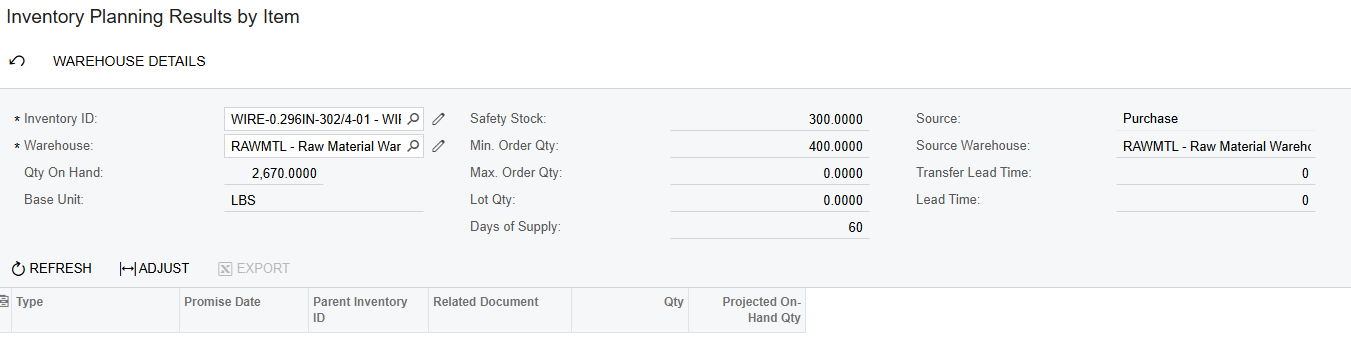

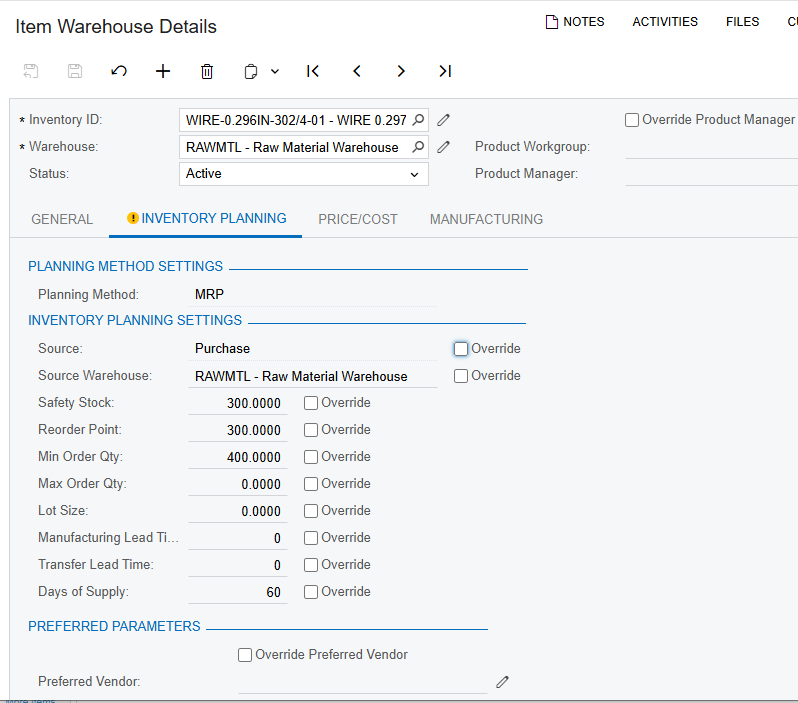

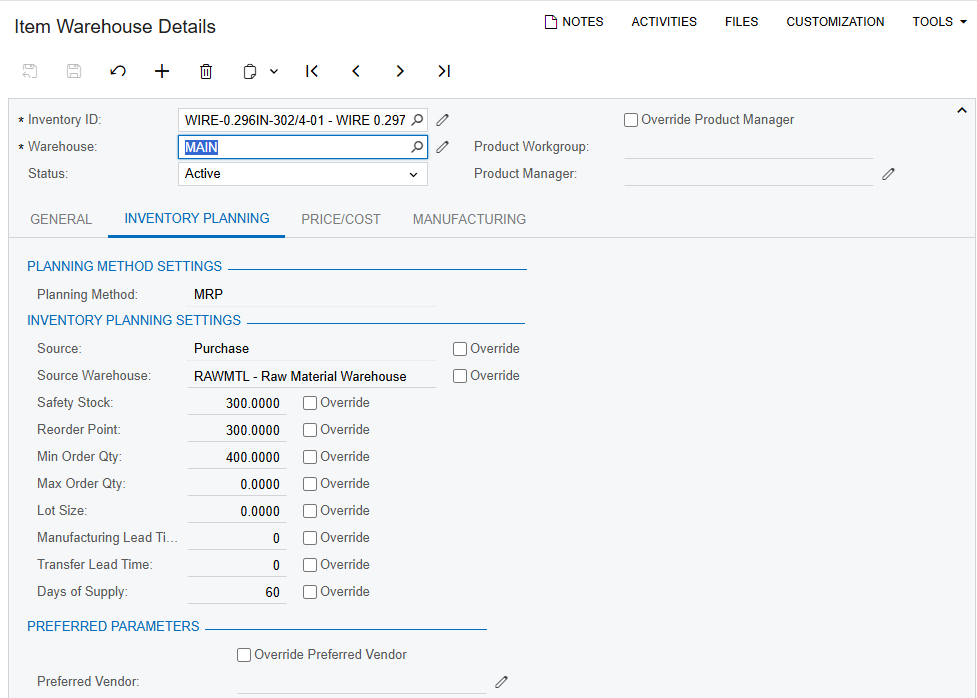

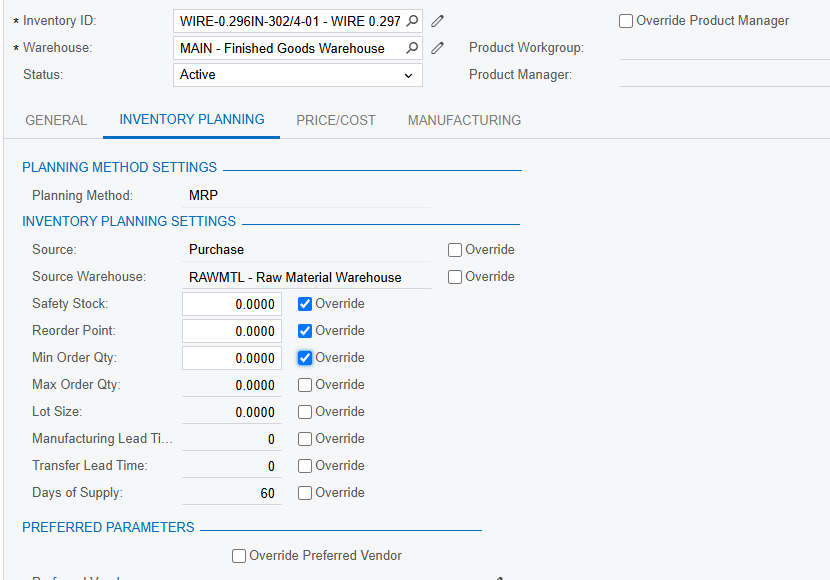

We have two warehouses setup in our system, MAIN (aka Finished Goods), and RAWMTL. All of our raw materials are inventoried in the raw material warehouse. We set the invetory planning values as shown below on a select group of raw material part numbers for testing:

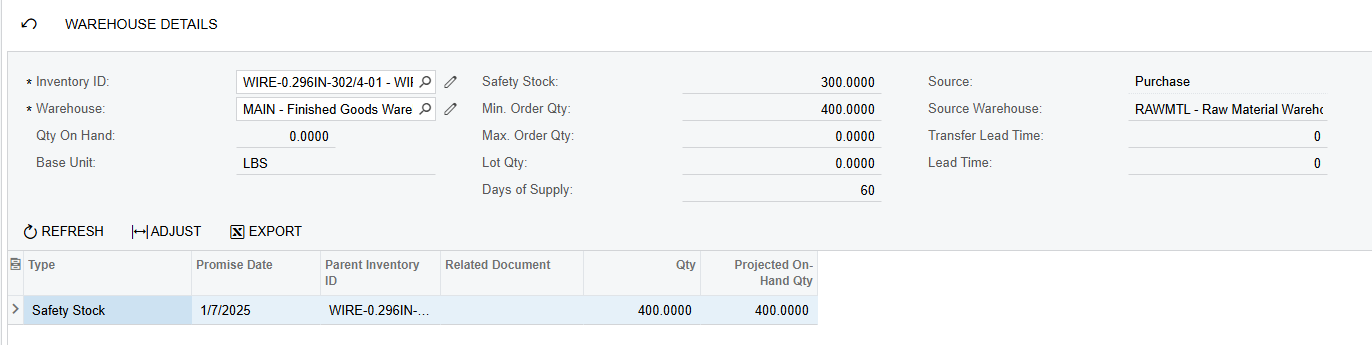

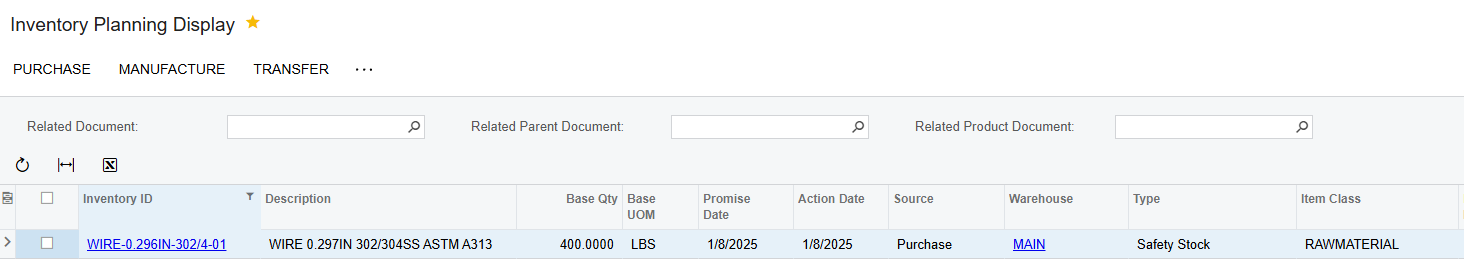

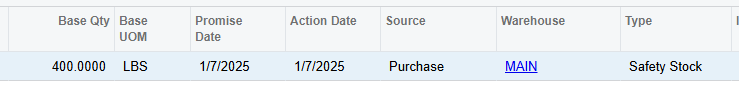

We then ran MRP and reivewed the Inventory Planning Display and were surprised to see that MRP was showing Safety Stock demand (see below) for us to purchase this material in the MAIN warehouse despite the fact that we have sufficient (greater then 300lbs) material on hand in the RAWMTL warehouse.

For materials that do not have sufficient on hand inventory in the RAWMTL warehouse, we are seeing demand to purchase this material for BOTH the MAIN and RAWMTL Warehouses.

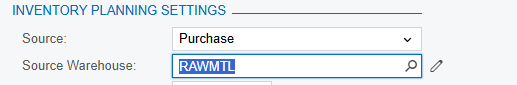

I have confused by this result as we have set the Source Warehouse on the inventory planning tab to RAWMTL as shown above. I would have expected MRP to only show safety stock demand for this warehouse, not both warehouses. Is this expected behaviour (showing for all warehouses), if not, do I have something setup wrong or did I find a bug in our version. We are running Build 23.211.0017

Look forward to hearing everyones thoughts.