Say production ticket AM01 has two 2 ops, 10 and 20..

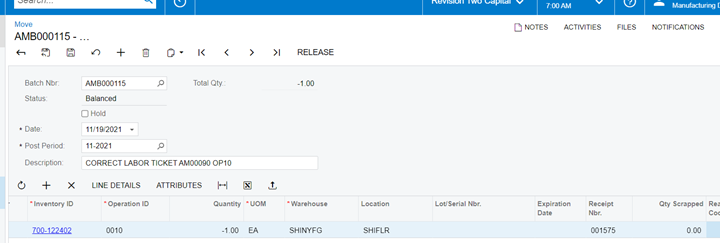

labor A on his clock entry put in finish 5 pieces, and supervisor release the labor ticket.. therefor RM and overhead and labor all posted to GL.

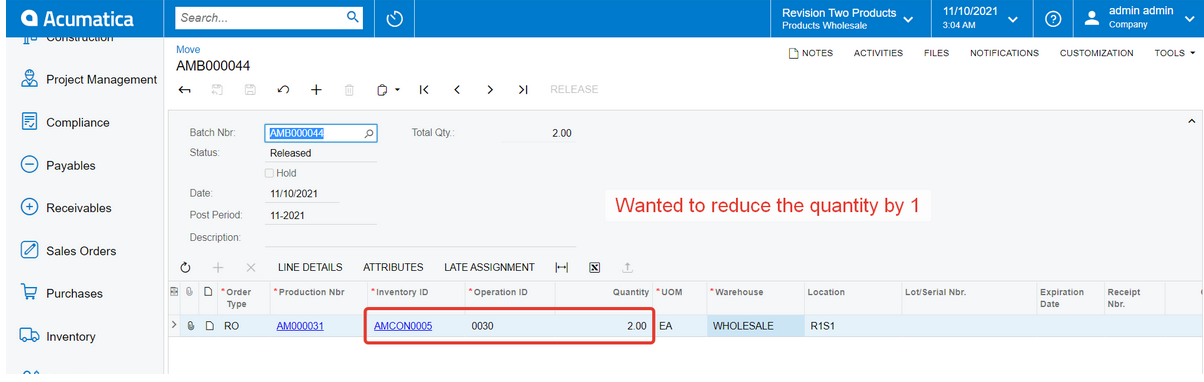

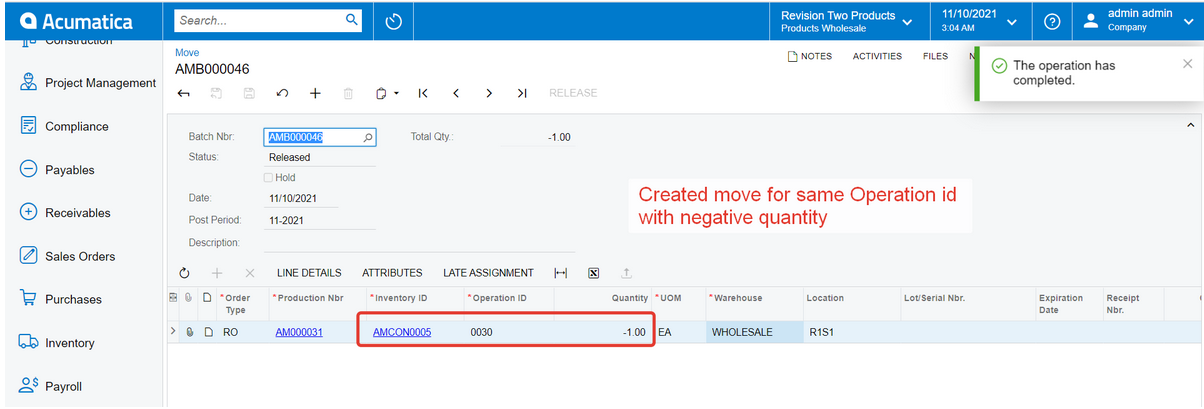

one day later, it turns out that A actually only finish 4 pieces instead of 5 in op 10

how to correct this?

Z