Hi Community,

I’m looking to get your thoughts on ETO manufacturing and custom-built subassemblies. Our client does a tremendous amount of Engineer-to-Order manufacturing. In many cases, their solutions may ultimately be built once, which may also include a reasonably large portion of their subassemblies, such as laser-cut sheet metal parts. The custom products and subassemblies often fit nicely into a handful of product classes, but in their current state, they are often creating new SKUs for ETO product and subassembly. These parts are virtually never in inventory beyond the time necessary to issue them to a production order or ship the FG to the customer.

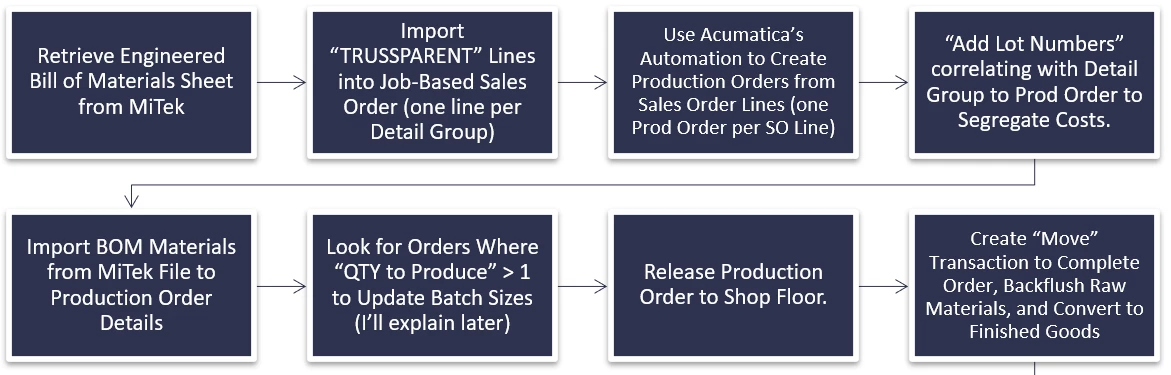

The client will be using CADLink, which will be used to generate SKUs, BOMs, and to update Production Orders. We can continue down this path, which is fine. With that said, it feels as though there could be some potential benefit of creating skeleton SKUs and BOMs representing generic versions of these products.

This is a solution I’ve used previously, where we’d create a MTO generic part and created a skeleton BOM that had only the routing. We would then generate the Production-to-Order Production Order and then import the materials afterwards. We would leverage other data elements to identify the items ordered and manufactured based on what was coming downstream from the CAD solution.

We also leveraged Serial/Lot Numbering and Specific Costing for COGS and Margin Analysis. Using Serial/Lot Attributes are also helpful for cross-referencing purposes between Acumatica and the CAD platform. In our minds, tracking the raw material usage and cost is the primary concern; the specific applications within Acumatica doesn’t have much meaning beyond drawings and maybe dims.

Our thinking around this approach is that the ETO designs and specs can live within the CAD solution; including the one-time parts that are also designed and manufactured. This could reduce the amount of noise and master record bloat within the ERP solution. Also, this approach can provide more flexibility within Acumatica in situations of redesigns or revisions since generic SKUs can take on any size, shape, and material requirements.

My question to the community is, are there others out there who have taken a similar approach or did you go for total parity? What led to the decision? If you took the approach proposed here, how did you “sell it”?

Tagging

Thanks all.