Acumatica allows expired materials to be used in production despite the fact that an expiration date is set. No warning to user or hard stop.

Does anyone have a workaround for this other than a custom inquiry that allows to find expired material and remove it from the shelves?

We are in a regulated industry (medical device) and current feedback from Quality is that the workaround is not sufficient and an active warning, if not a stop, from the system is the minimum that has to be implemented.

Acumatica allows to use expired materials in production - any workarounds/solutions?

Best answer by jharris

Acumatica allows expired materials to be used in production despite the fact that an expiration date is set. No warning to user or hard stop.

Does anyone have a workaround for this other than a custom inquiry that allows to find expired material and remove it from the shelves?

We are in a regulated industry (medical device) and current feedback from Quality is that the workaround is not sufficient and an active warning, if not a stop, from the system is the minimum that has to be implemented.

Hi

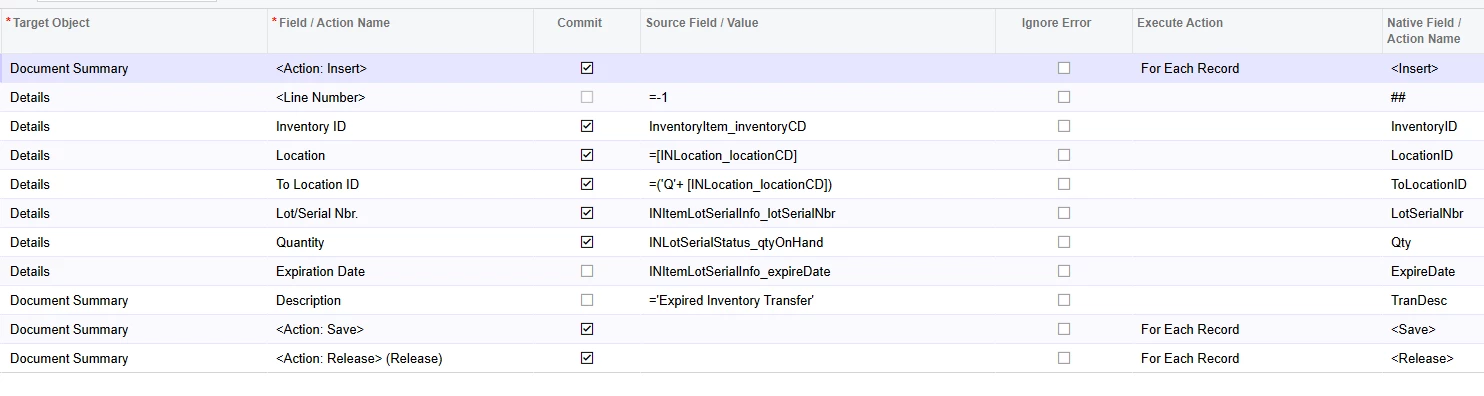

Here’s another option that might be able to work in a pinch… You could set up a business event to transfer the out of date materials to a do-not-consume location (Can also be used for expired product to transfer it to a do-not-sell location).

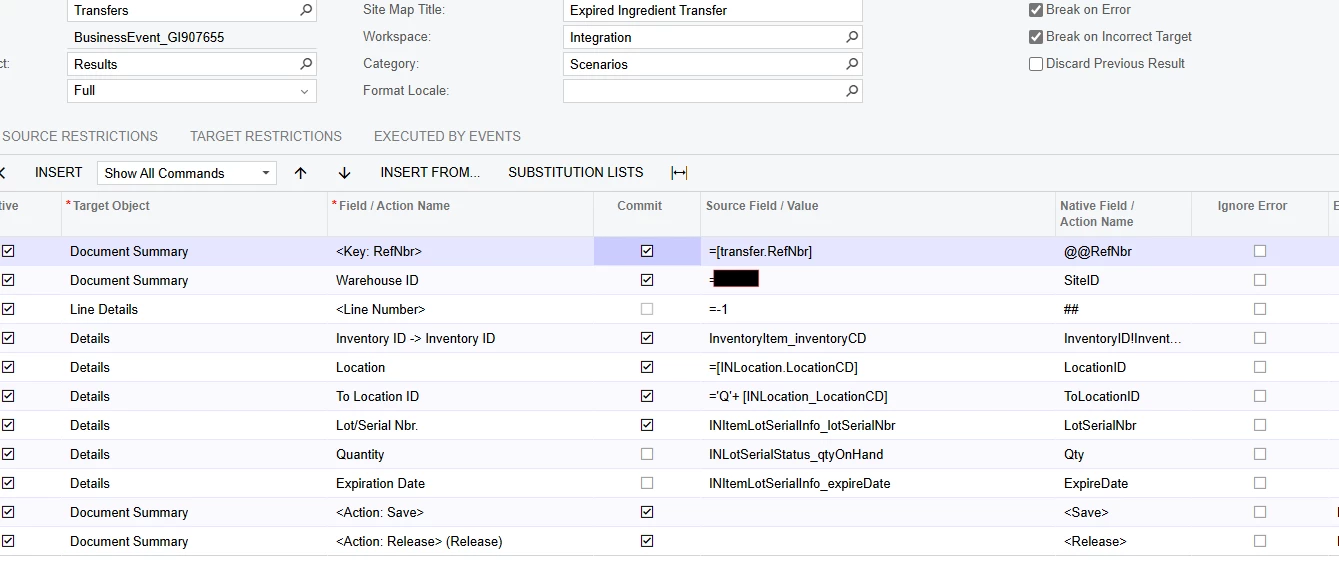

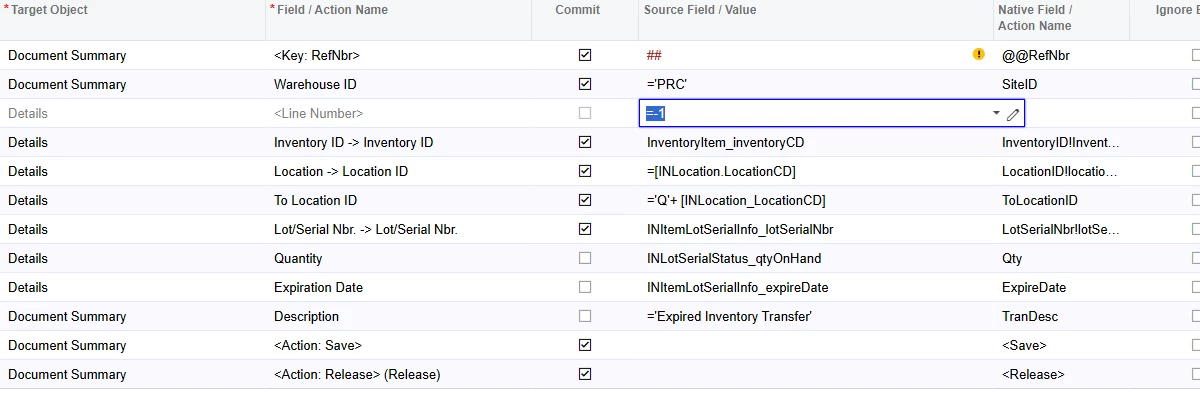

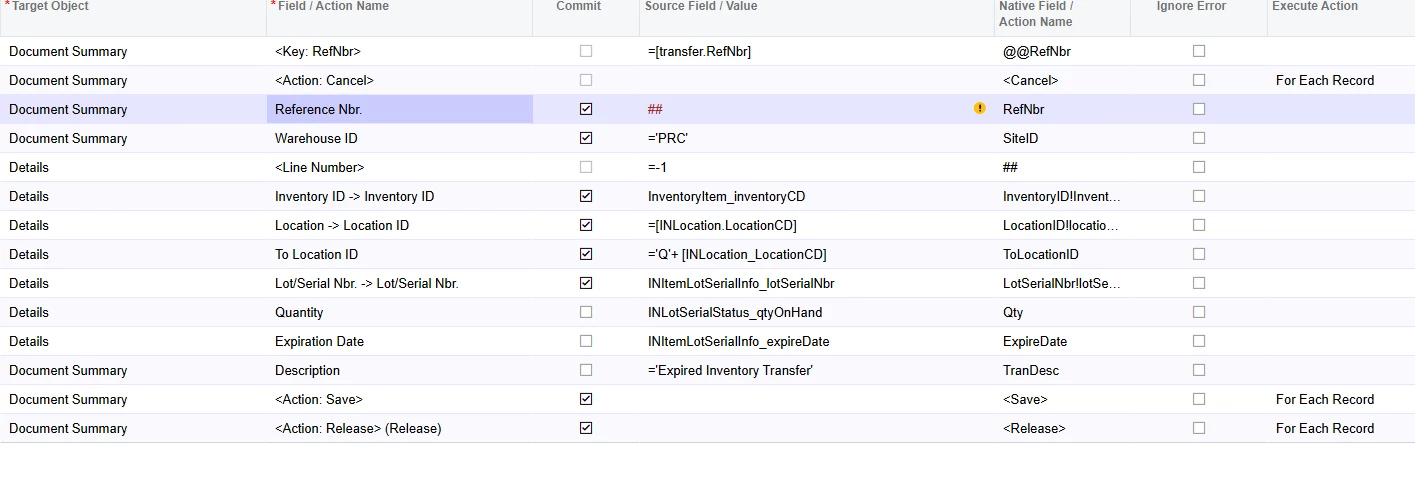

You’d do this by setting up a GI of the inventory, filtered by any LOT or Expiry date older than your parameter. Using this GI as the source data for an import scenario, the system will initiate the transfer. Set this up daily, weekly, monthly, or even hourly or every 5 minutes depending on your needs.

When setting up the business event, have the trigger be a change in the GI, and the transfer be a 2 step transfer to a damage location (So it requires manual intervention to complete the transfer). Alternatively if you’re not mixing expiration dates in a locations (At issue), you could also change the location attributes to not allow production from that location as well. Another option is to transfer it to a phantom Damage Warehouse altogether where the inventory can’t be used for production.

While yes, preventing this in a new feature would probably be ideal, there may be a use case for overriding this and allowing it as well. Using a business event and the solution I’ve provided as a “Workaround”, might allow for even more flexibility as you can set even more parameters and maybe only set it for specific components, or a specific time after expiration. This allow much more flexibility for the business use cases.

Hope this helps!

-James

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.