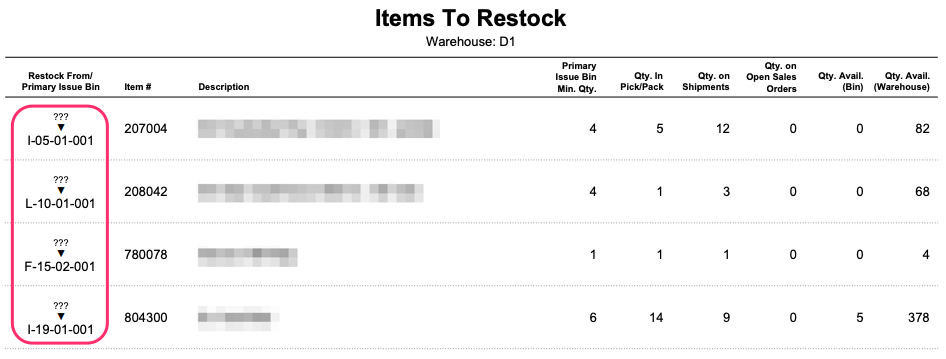

I’m currently upgrading to 21r2. I have a business need for a warehouse restocking report. This is different than a replenishment or purchasing report.

My goal is to make it so a warehouse picker never arrives at an empty Default Issue From location because it’s already been refilled by restocker. FIFO must be factored, when applicable.

Consider an example Inventory ID `12345` that is Lot Tracked with a FIFO issue method. This item is stored in 4 different locations within a single warehouse:

Location IDs for `12345`:

——————

PRIMARYPICK — Default Issue From location (this is where we pick from)

STORAGE1 — Lot #3 (newest inventory)

STORAGE2 — Lot #2 (older inventory)

STORAGE3 — Lot #1 (oldest inventory)

I need a report (or generic inquiry) to tell my restockers to refill the PRIMARYPICK for `12345` *before* the inventory runs out. It needs to direct them to the correct Location ID that should be used for restocking the PRIMARYPICK. In the example above, this would be STORAGE3 because it’s the oldest inventory.

The Create Shipment action sort of does this now. If the PRIMARYPICK is empty, the shipment will use correctly use STORAGE3 for the inventory transaction.

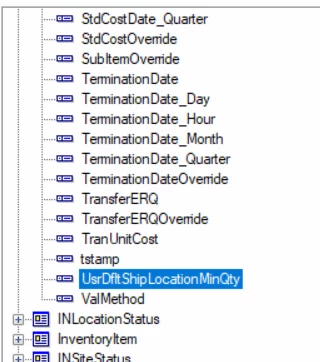

It’s easy enough to identify Default Issue From locations with a qty less than X. But I can’t figure out a way to identify which random storage location should be used to restock the Default Issue From location with lot or serial tracked items.

Is there anyway to mimic whatever logic Create Shipment is using in a report and/or Generic Inquiry so I can be proactive about restocking the Default Issue From location?