Soon to go live on Acumatica, and this is my first post so apologies if this has been answered anywhere.

Need:

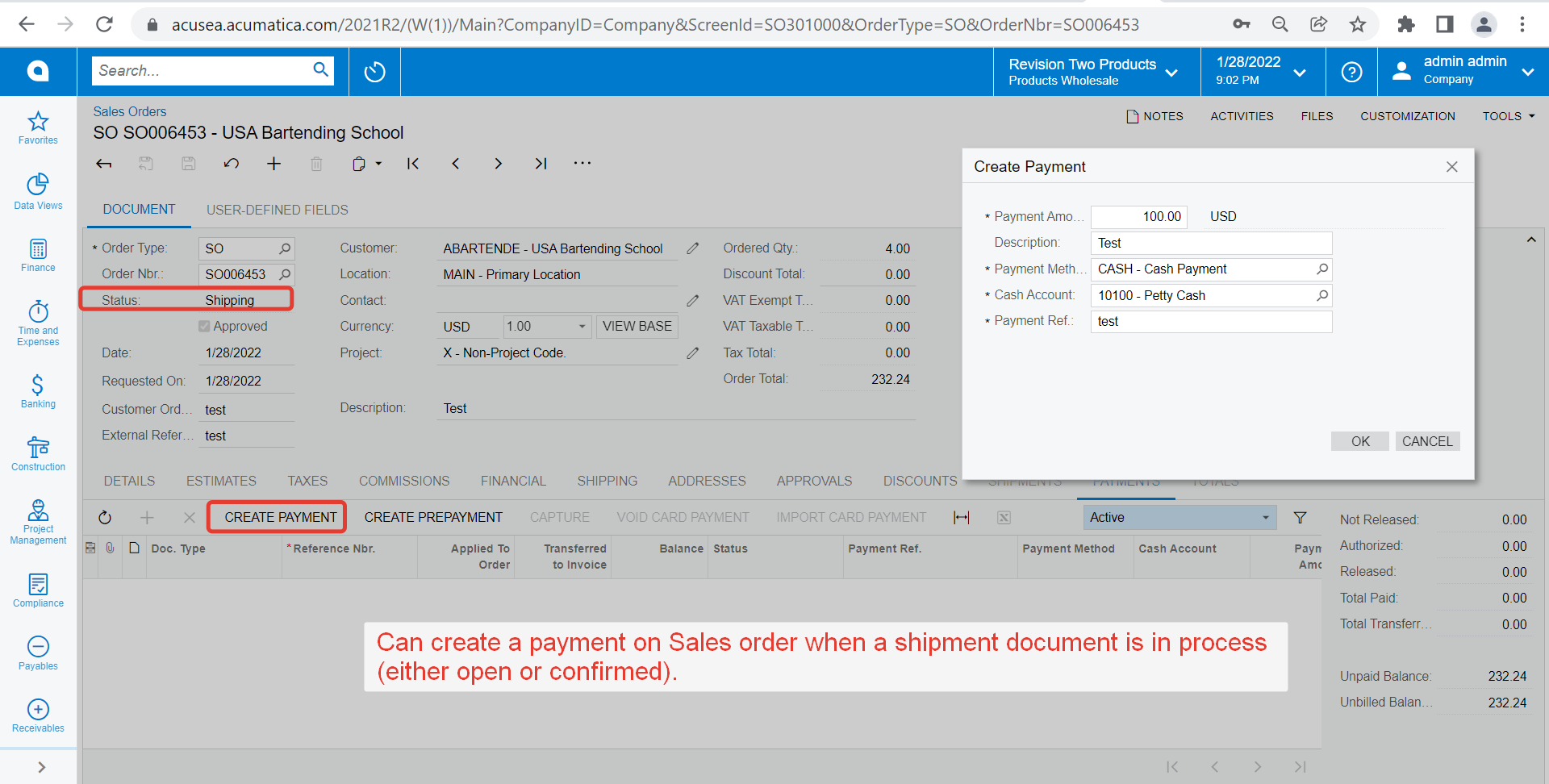

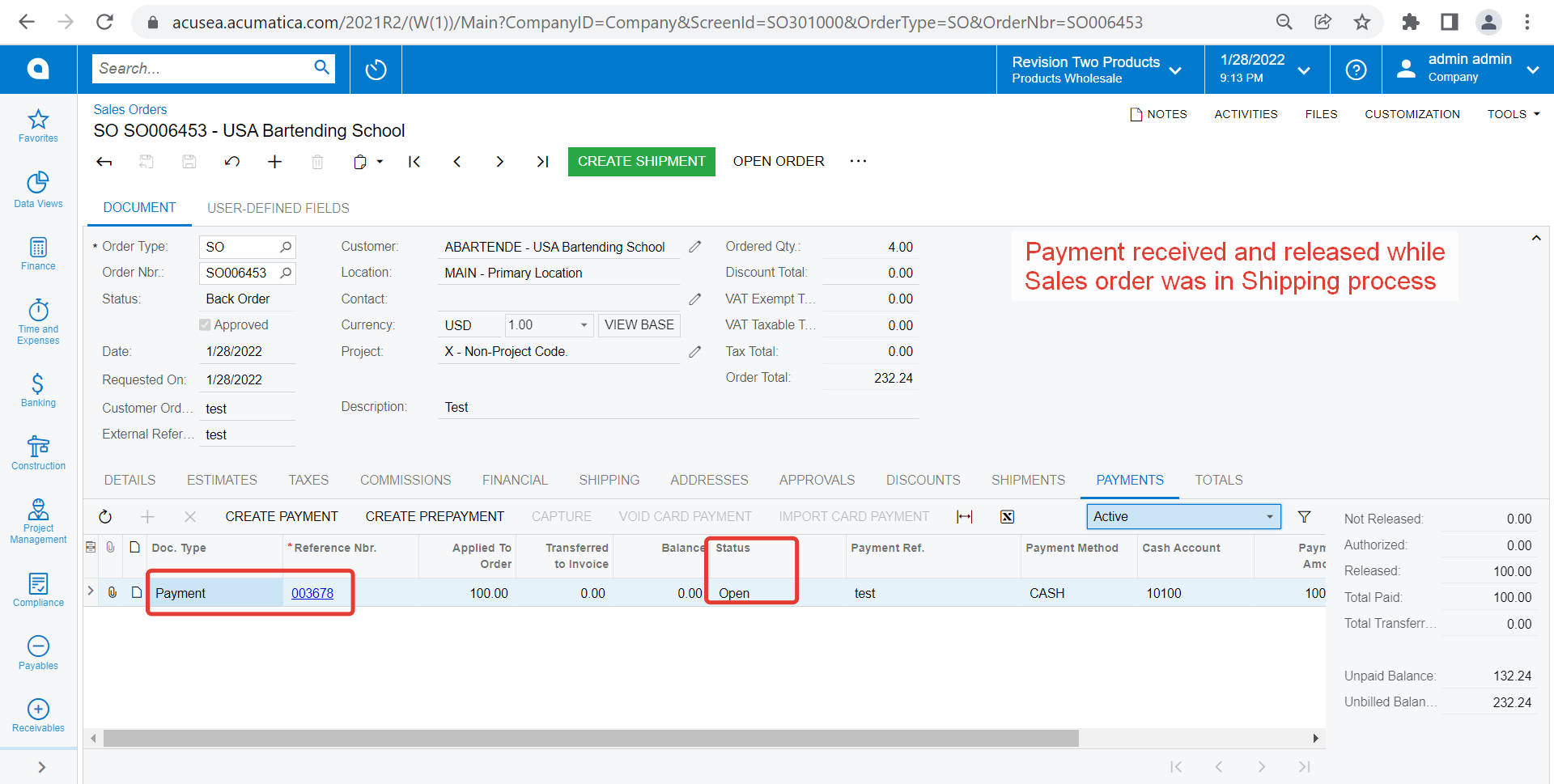

In short, looking for a solution that would allow us to take payment against a Shipment with picked or allocated quantities vs. what Acumatica allows which is only payment against an Order or an Invoice.

Scenario:

We ship goods based on square footage (leather hides), such that a customer can order 1 hide, but in our Pick/Pack/Ship against a Shipment, we can pick 45square feet, 50square feet or 60square feet - all of which is acceptable in our industry and decided by the Picker.

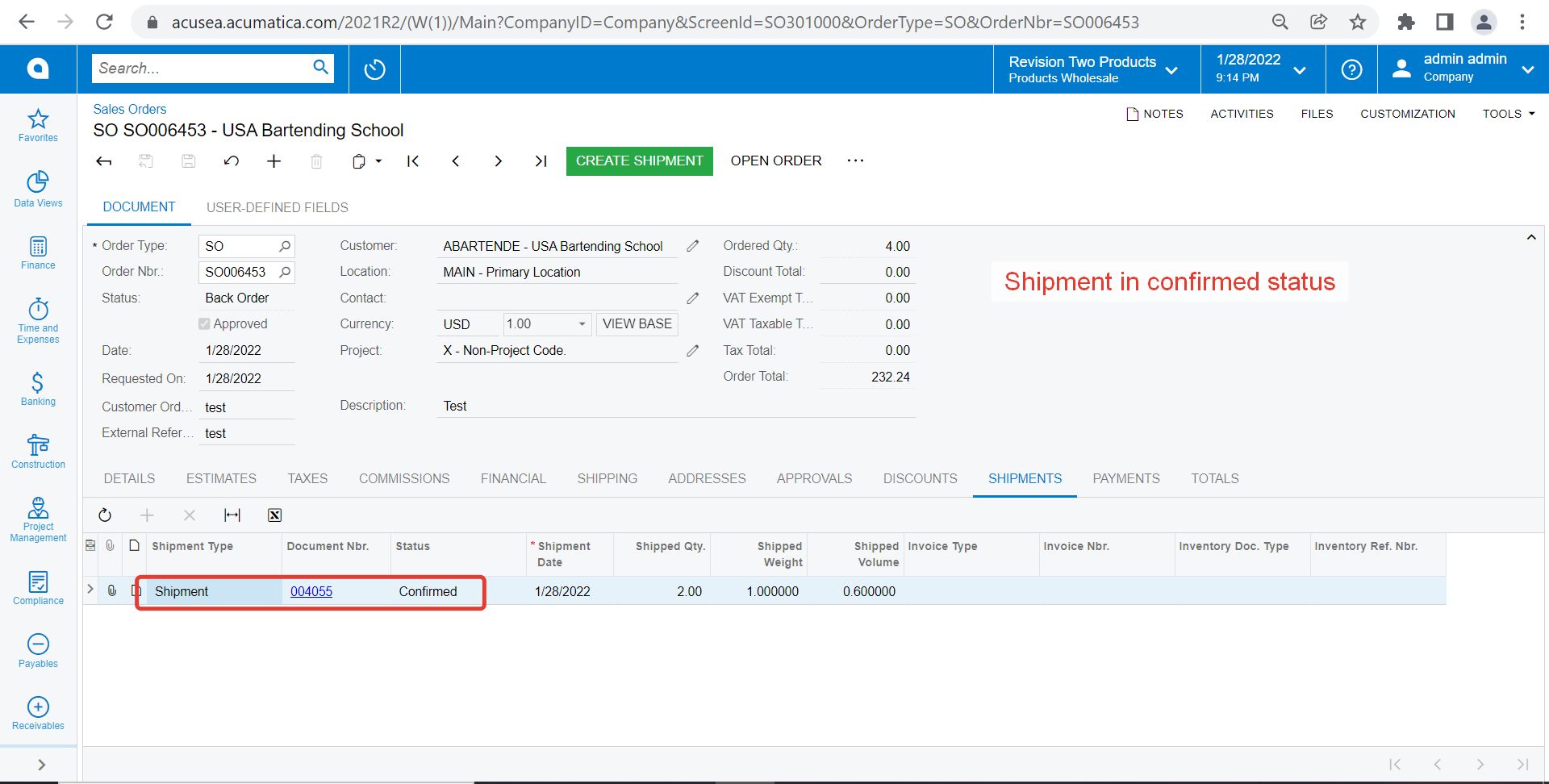

In the case of a prepaid customer, there is no way to take payment against the picked item(s) on the Shipment. My understanding is we have to confirm shipment, create invoice and then take payment against the invoice…..which raises the potential for the Shipper to pack goods up, label them and goods leave our warehouse in advance of payment being received and potentially, credit card payment is denied when payment is attempted on the invoice.

Additionally, for many sales we are required to pick the goods to get appropriate totals that affect our packaging and freight/duty rates for international prepaid delivery and must provide a Proforma to the customer to pay in full before goods ship.

The work-around of creating Shipment, picking goods, determining freight/import costs, then cancelling the shipment, adjusting the Sales Order to equal picked values and providing that for payment to customer would require us to “re-pick” the entire shipment from a systems-standpoint once the order is paid, and in the interim when payment could be 30 days from time of picking, our inventory visibility/demand is obviously not correct.

Other work-around is a simply business process that Shipper must not ship until given the okay by the Front Office, but that introduces human error we’re trying to avoid.

Any help/direction appreciated.

RH