Hi everyone,

We’re running into recurring issues in our Distribution Center related to lot-tracked inventory and availability for shipping. We are semi-new to Acumatica, having gone live in March, so we’re still ironing out some processes.

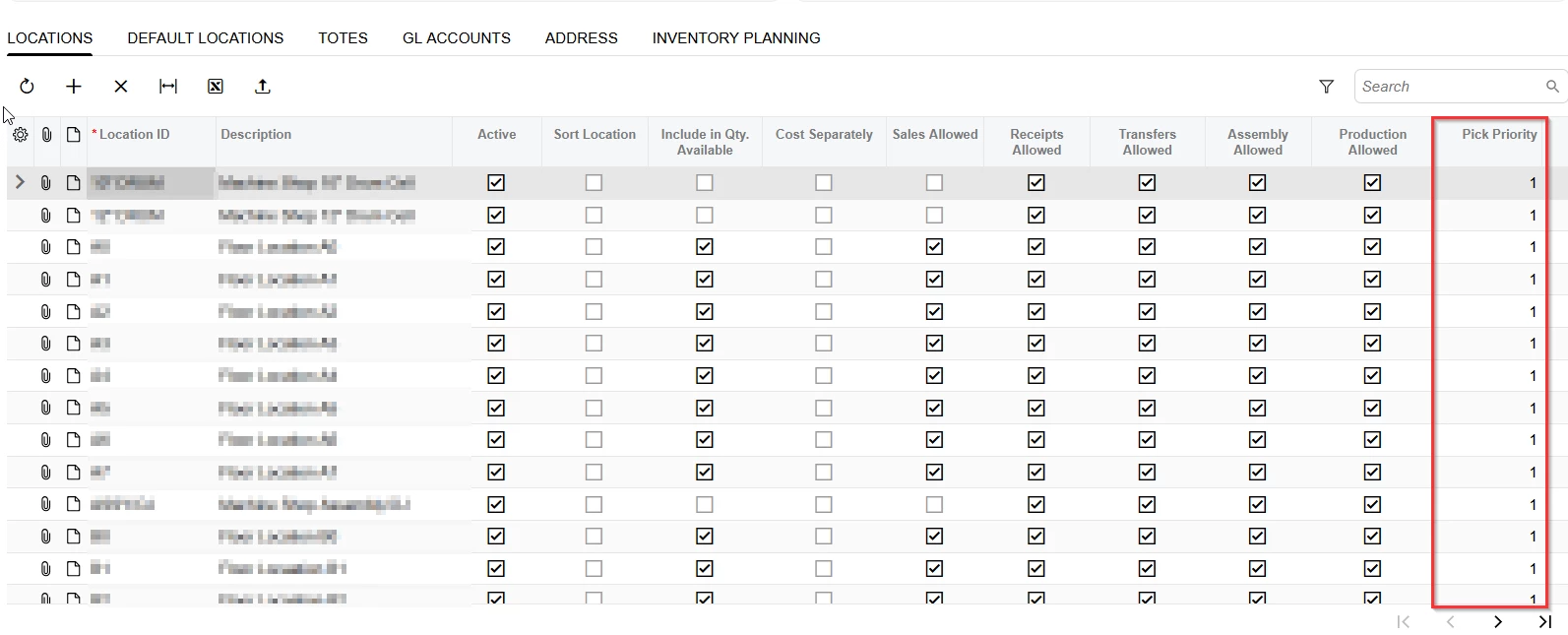

Our Lot/Serial Class is set to “User - Lot Tracked”, meaning the system does not assign specific lot numbers when generating pick lists - only the location is specified.

Here’s the problem:

- The picker is directed to a location (e.g. F-A01-) to pick any available lot.

- However, the lot they select is often showing an error (Something like “lot unavailable” or “inventory will go negative”), even though it physically exists in that location.

- Other times, picking and packing go smoothly, but at Confirm Shipment, we get an error saying the inventory will go negative - even though nothing appears to be oversold or misallocated.

- When we double-check the Inventory Summary screen, it shows more than enough quantity available to complete the pick lists, yet Acumatica still throws the negative inventory error.

This is creating confusion for our team and causing delays in order fulfillment.

Has anyone else experienced this behavior?

I’d love to hear how your picking process is structured, especially if you’re also using “User - Lot Tracked.”

Any insight or best practices would be greatly appreciated!

Thank you!