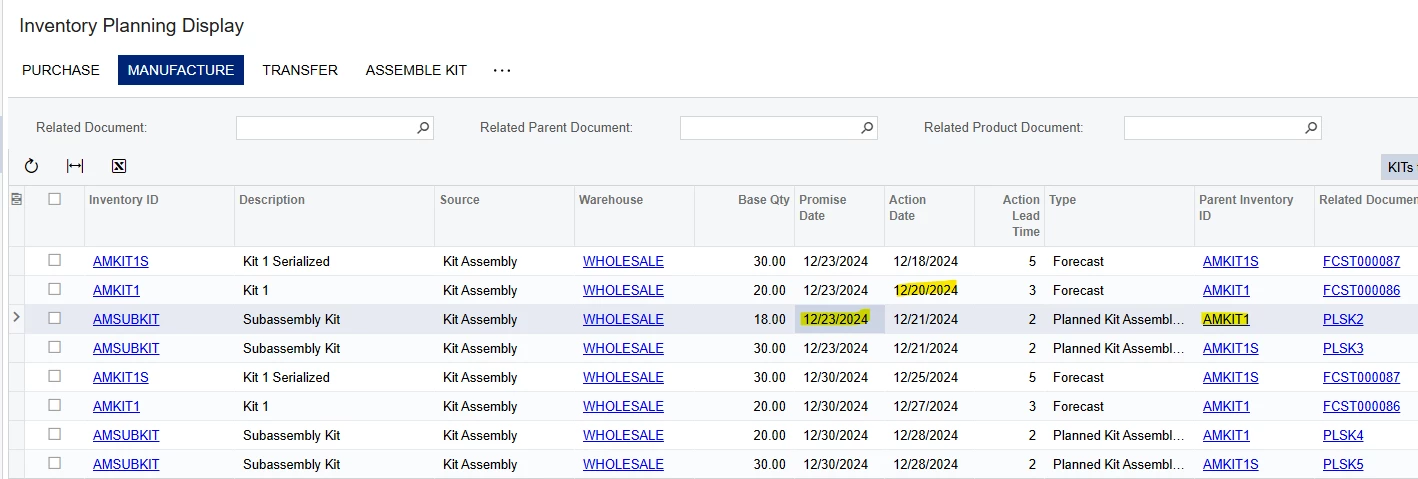

MRP/DRP seems to ignore the lead time for kits with dependent demand. The promise date for a subassembly used in kit should be the action date of the parent item. In my example, the AMSUBKIT promise date should be the Action Date of AMKIT1

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.