Hi everybody,

We are looking for a solution on how to convert a stock item to another new item when inventory was moved to a certain Warehouse.

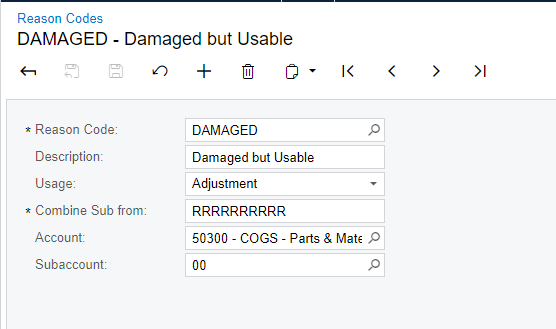

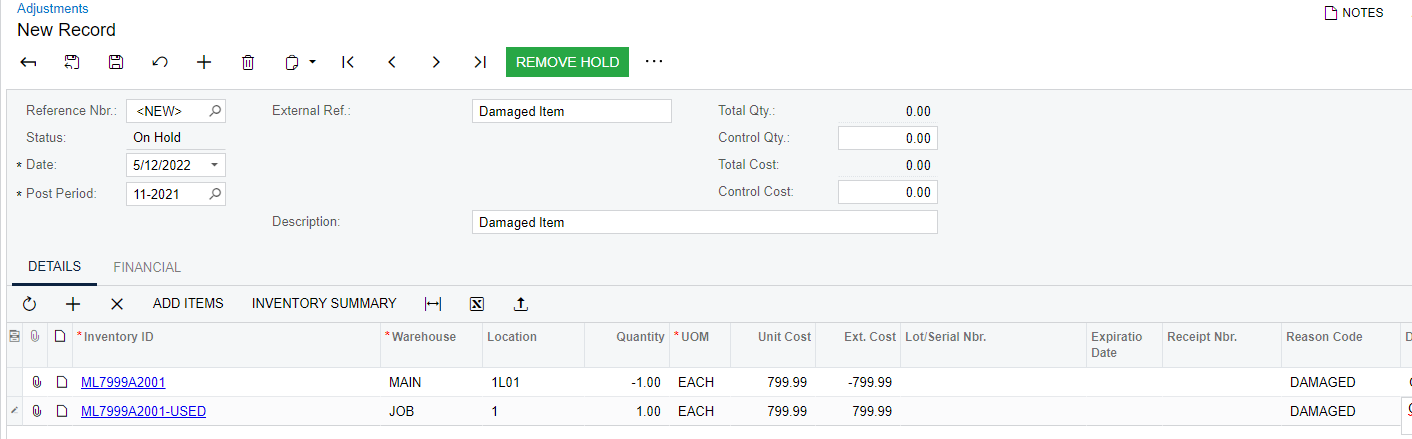

Example: Warehouse 1 is the main warehouse where we sell Product having SKU AAA for it’s original price. Now, there is a Warehouse 2 where we move items that are still usable but has quite damage and sold for lesser price. We need that Product AAA converted to a separate product, like SKU AAA-2, since we don’t want to track the inventory of items already moved to Warehouse 2 on the original item AAA.

Will that be possible? That transferring an item from one warehouse to another will also move the quantity from original item SKU to new (or another) SKU?