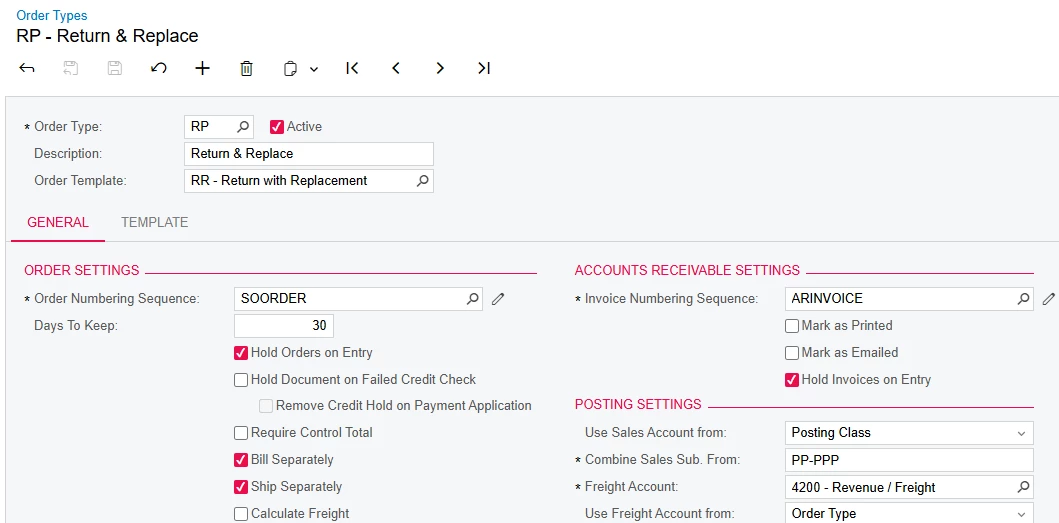

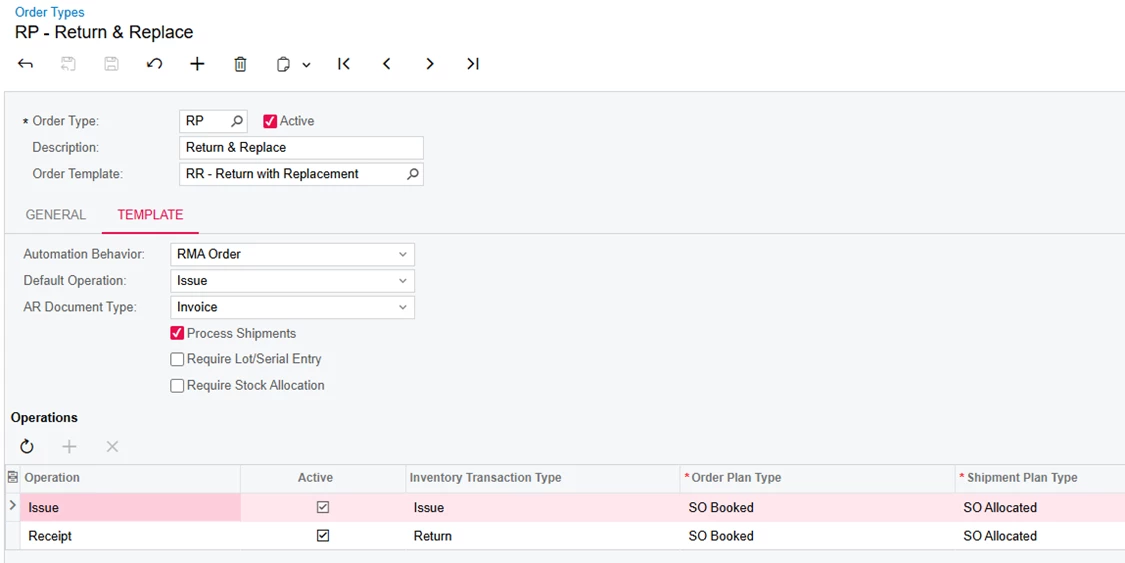

How do we use RR when we ship the replacement and pick up the return at the same time? We typically send the replacement item via company truck and pick up the defective/warranty item at the same time (or sometimes a day or two later, as the original item still needs to be extracted when the replacement item gets installed).

The problem we are having is that the replacement shipment needs to be Confirmed before the Return item can have it’s shipment created. The SO entry appears to function the way we desire with the replacement item and the return item on the same transaction, but we have no document(s) for our driver and the customer to indicate both the replacement and the return being processed at the same time.