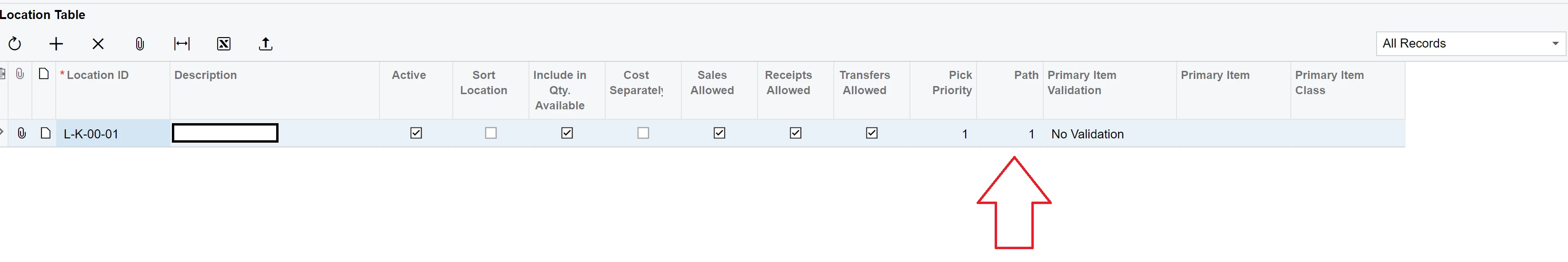

In the Warehouse settings screen, you define your Warehouse Locations in the Location Table. There is a field called “Path” in this table, but I can’t find an explanation anywhere of what this field does/what it means.

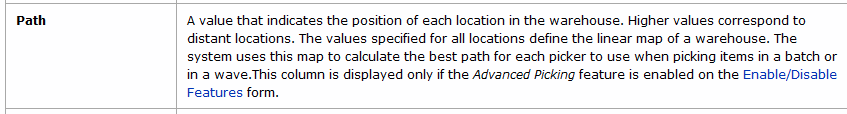

In the Pick/Pack/Ship workflow, the handheld device keeps asking you to scan the nearest warehouse location. This never made sense to me, because there doesn’t appear to be anywhere in the system where you can tell it the distance between locations. So why would it care where you are currently, if it has no idea what the most efficient next location would be to send you to?

So I’m wondering if this Path field maybe has something to do with Pick/Pack/Ship and its ability to distingish between Locations that are far away or close to one another?