Hello,

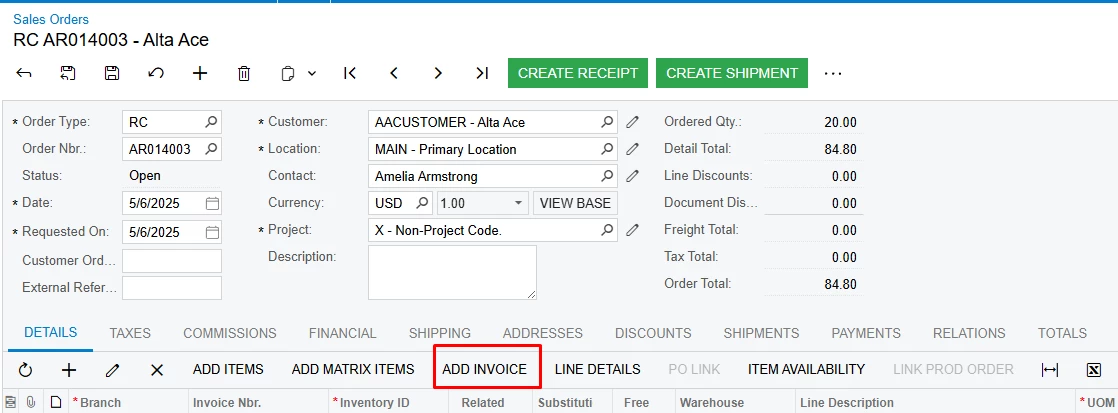

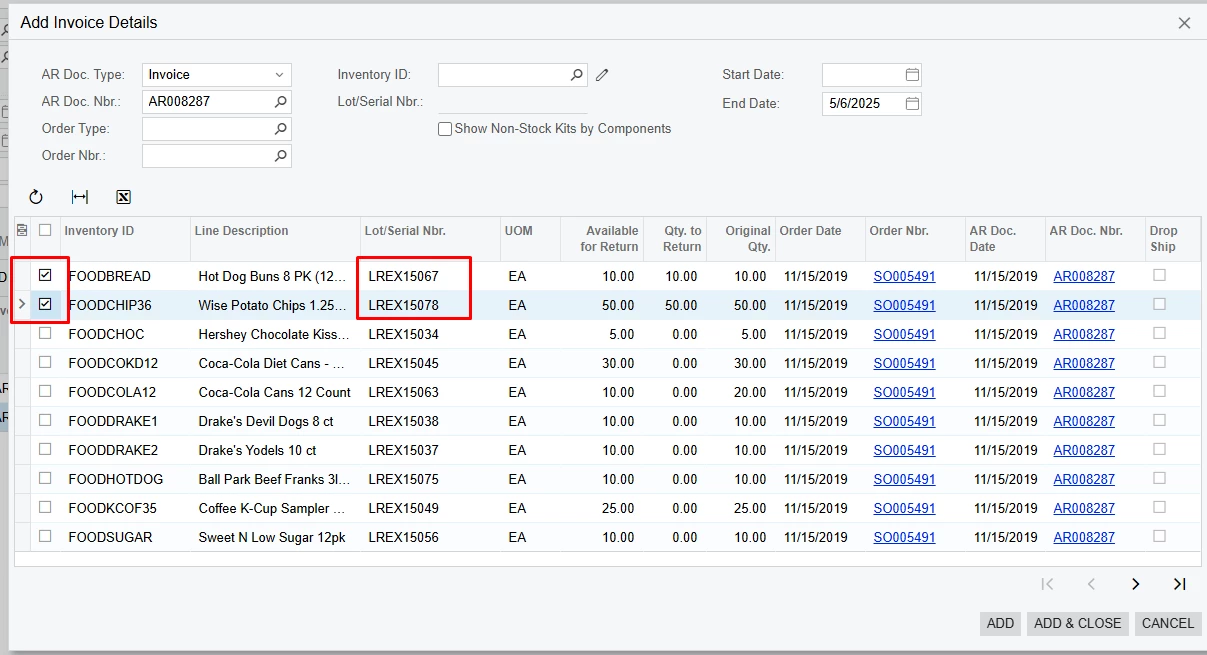

We’re trying to process a Credit Return where some of the returned product goes back into inventory, while the rest is damaged and should not be restocked.

What is the recommended process in Acumatica to return only part of the product to inventory and exclude the damaged portion? Is there a way to split the quantity between what’s restocked and what’s written off, all within in the same return?

Thanks in advance for your help!