This topic provides a workaround to calculate the max possible quantity that can be assembled for a non-stock kit or a stock kit. And uses an import scenario to update an attribute on the non-stock kit for the max availability.

Assumptions:

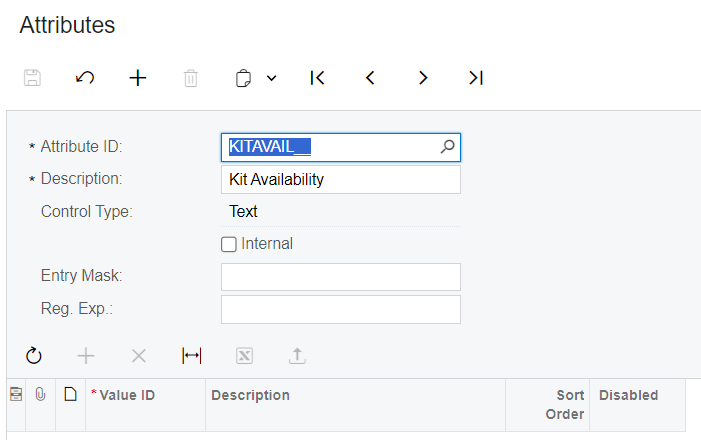

1-Create an attribute KITAVAIL and assign to the non-stock kit class

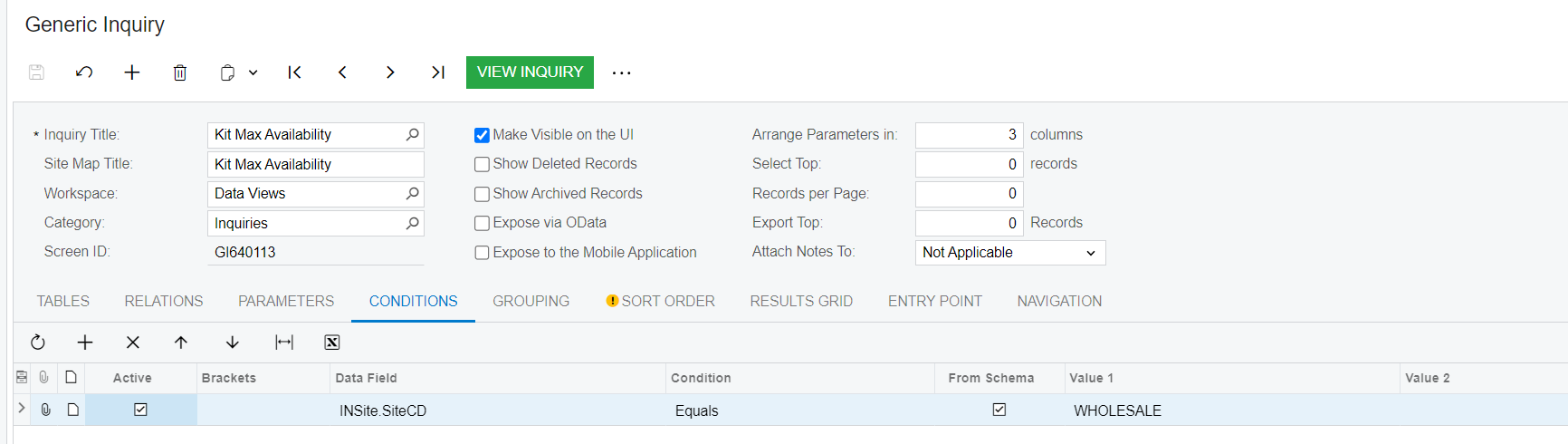

2-There is a condition to filter on the warehouse storing the components used to assemble the kit

Hint: The GI pulls stock and non-stock kit. it can be enhanced to only pull non-stock kit.

Precaution: The import scenario that I attached is only updating the availability for non-stock kit. it will FAIL on stock kits, you might need to create another import scenario for this purpose.

How to use it:

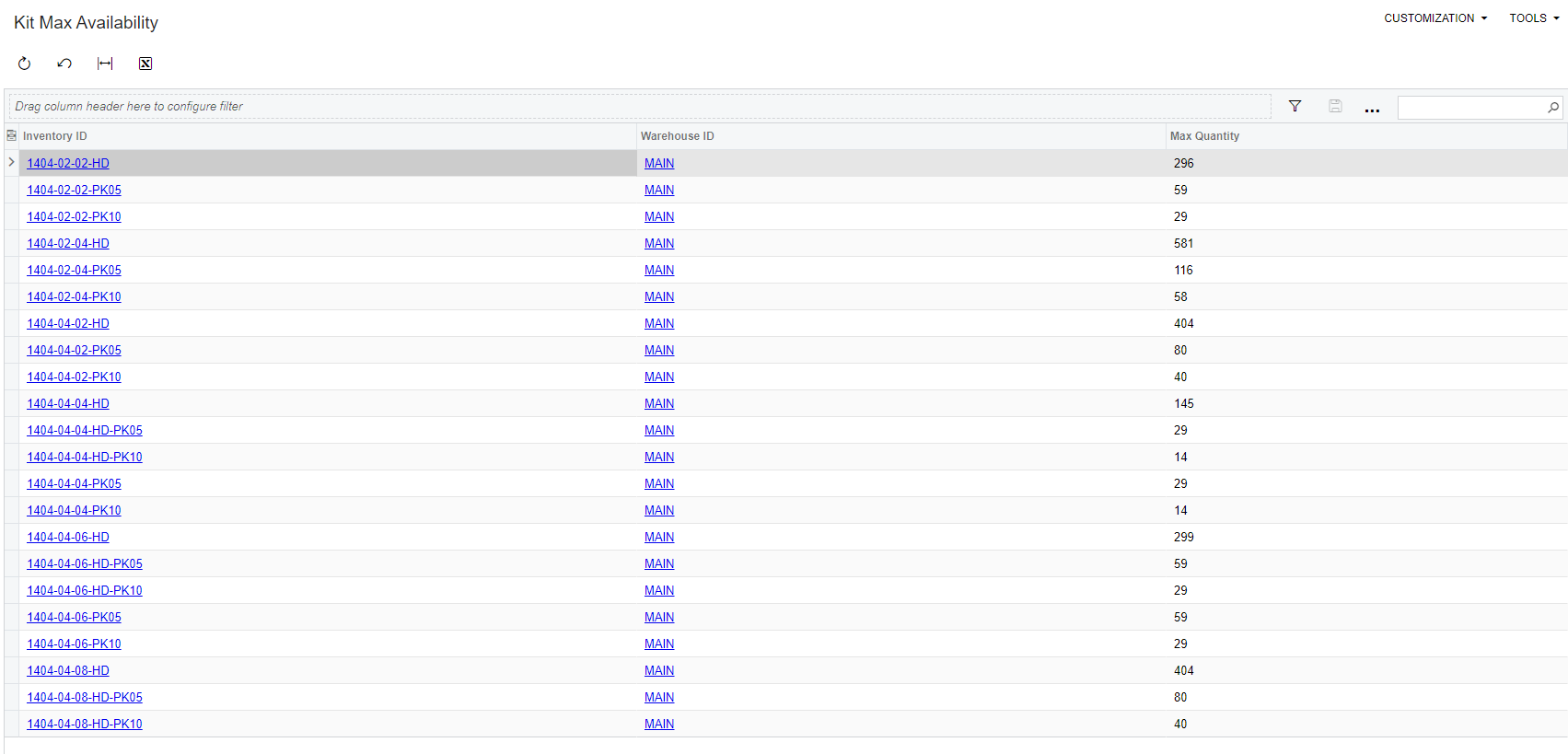

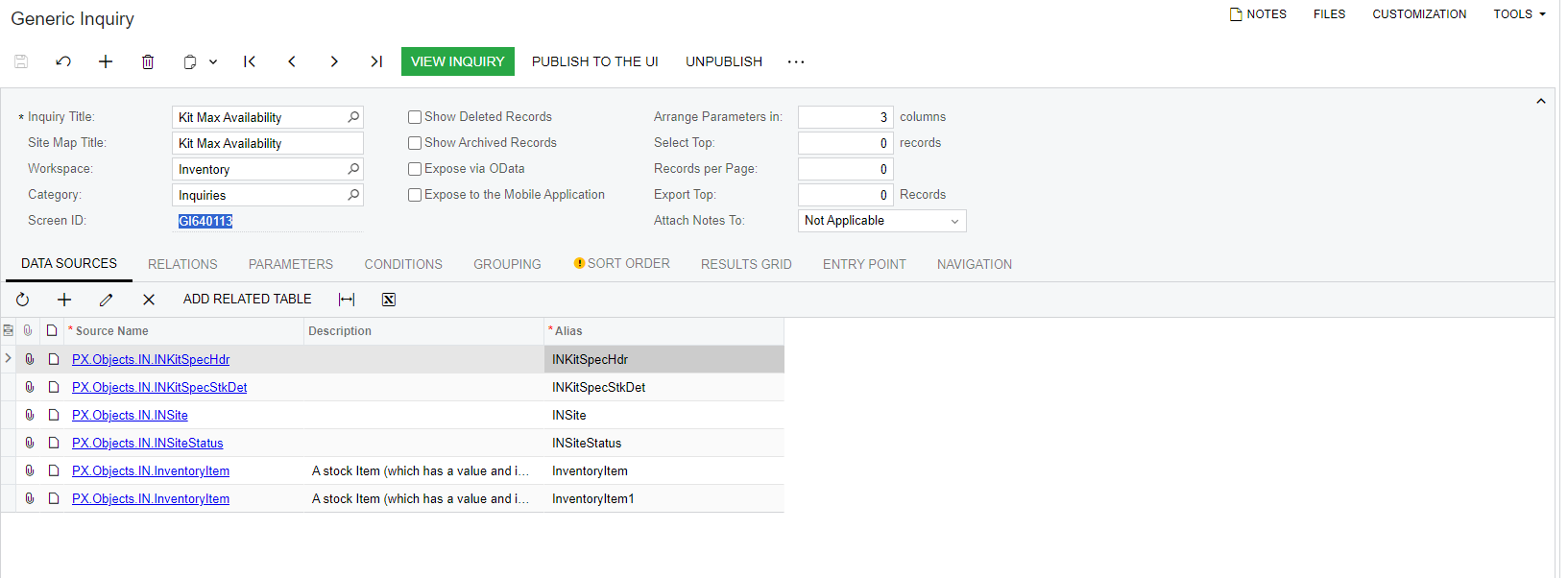

1-Import the GI:”Kit Max Availability.xml”

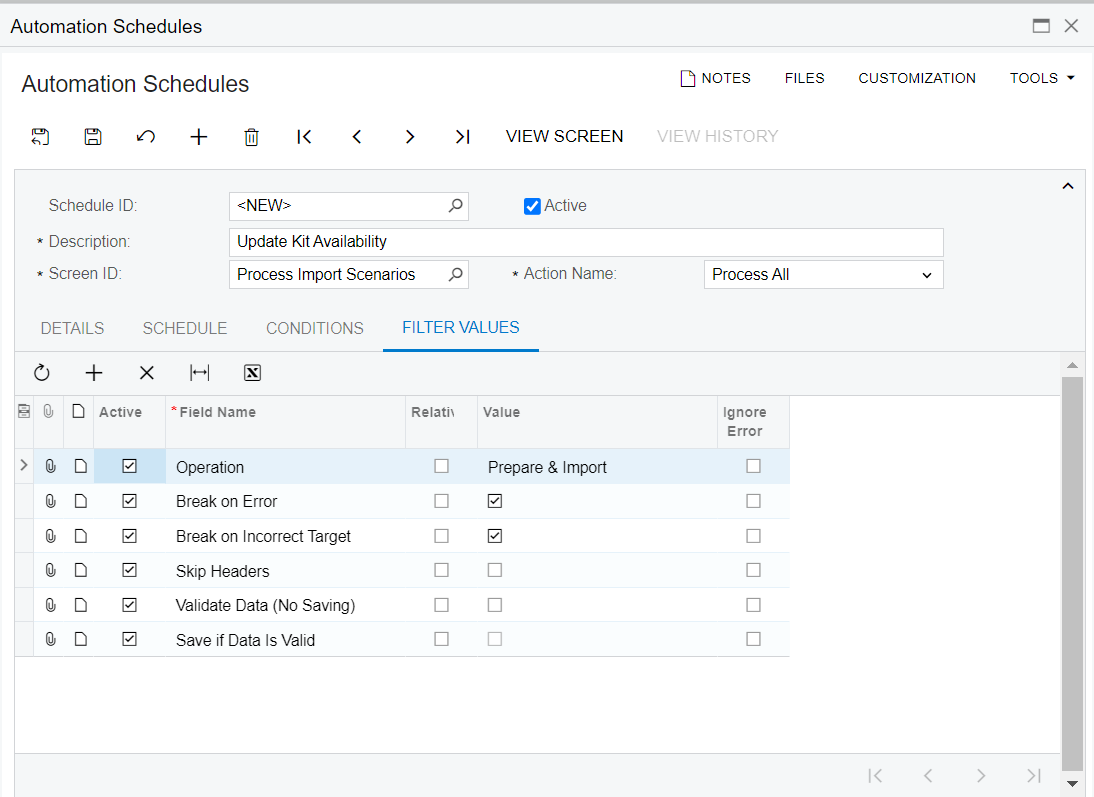

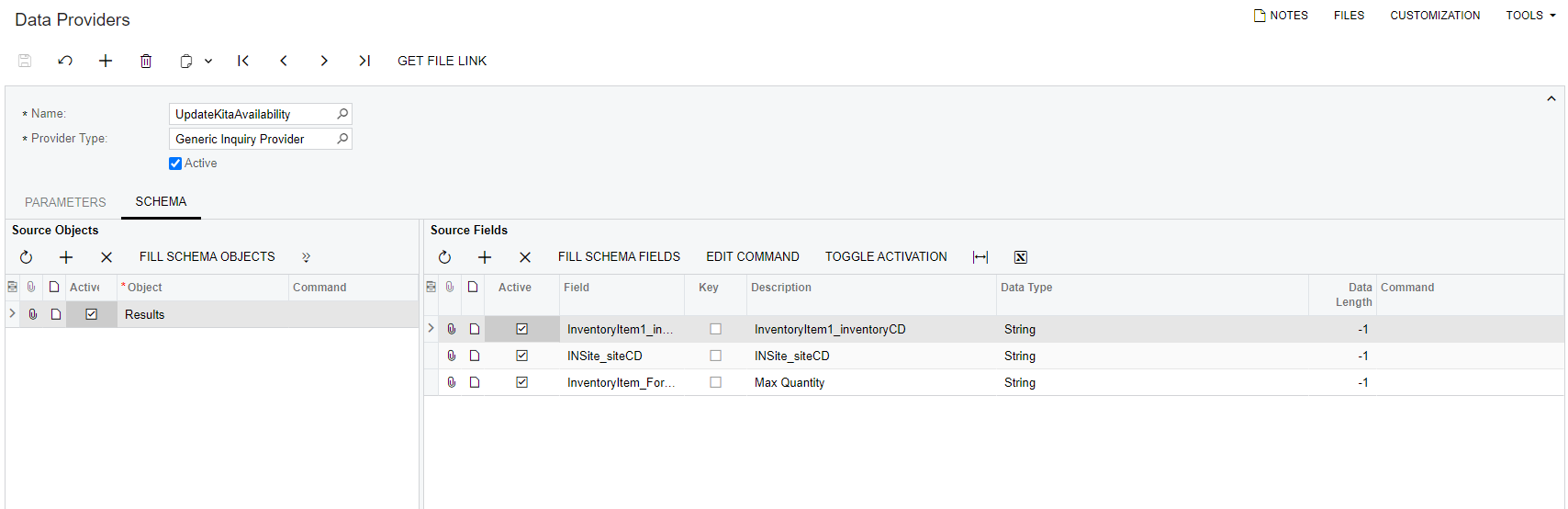

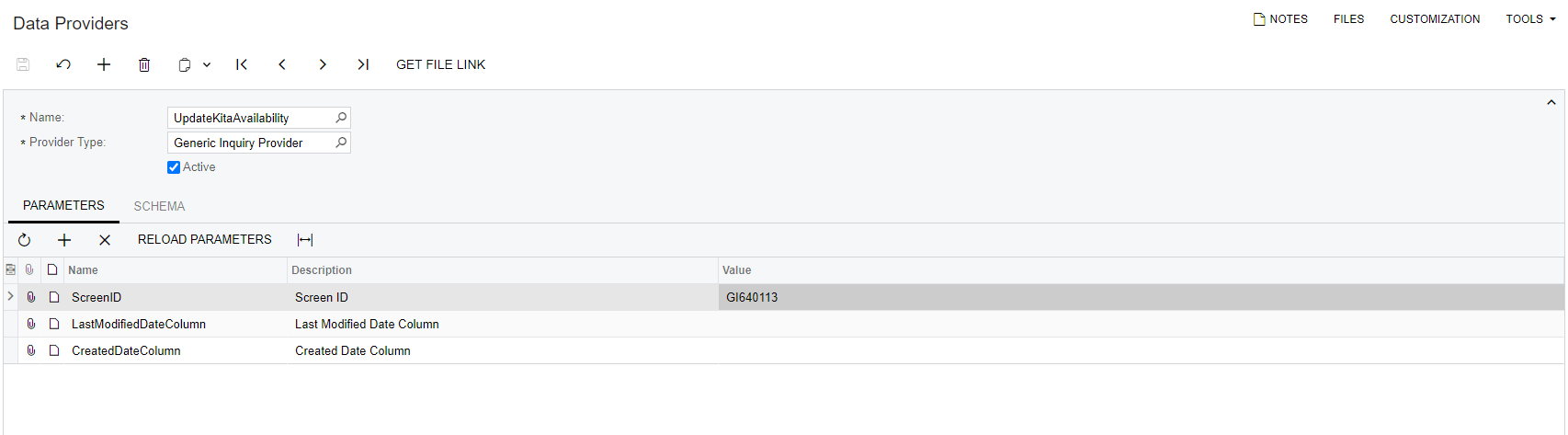

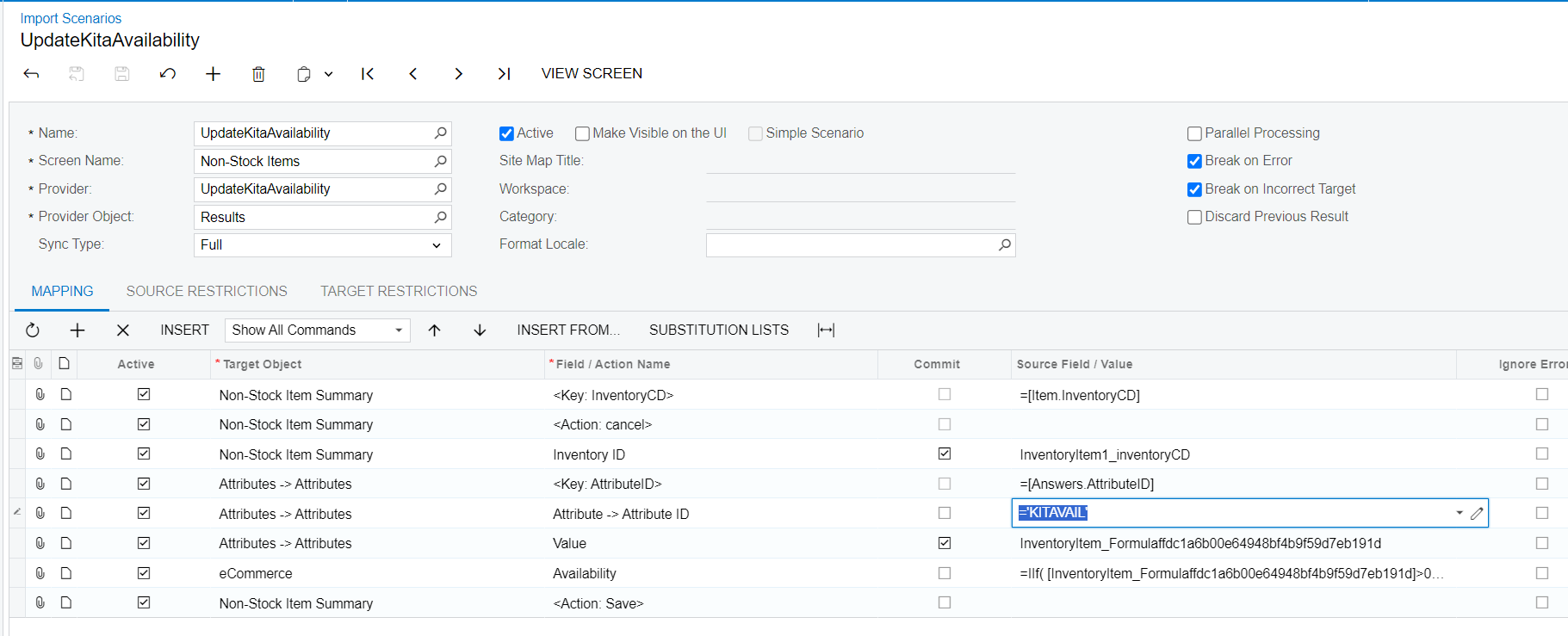

2-Create import scenario:IN202000-UpdateKitaAvailability.xml

Since the import scenario is based on a GI it is dynamic, you can run it manually or run using a schedule.

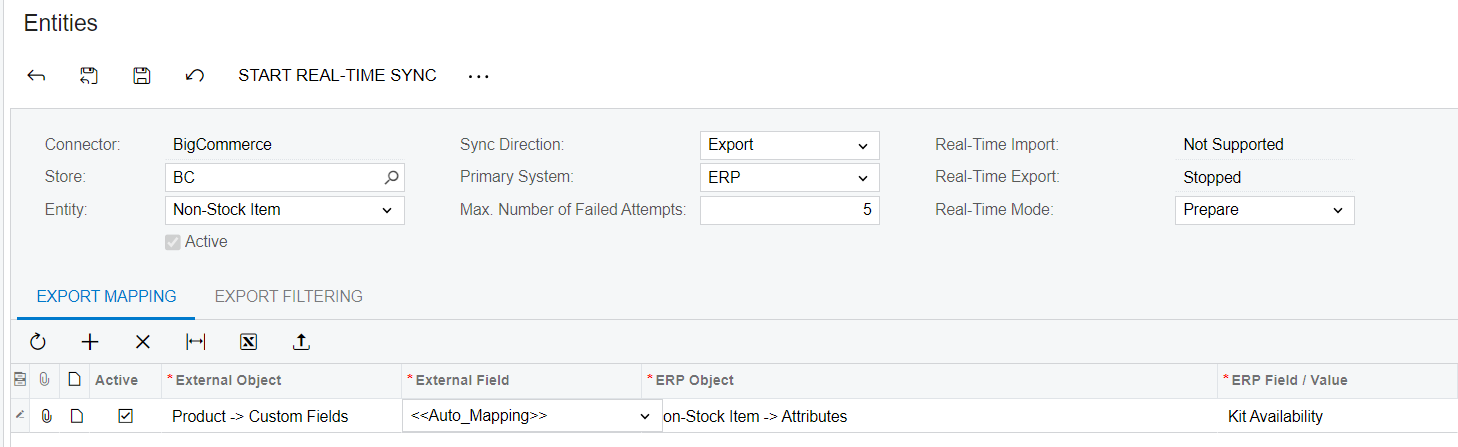

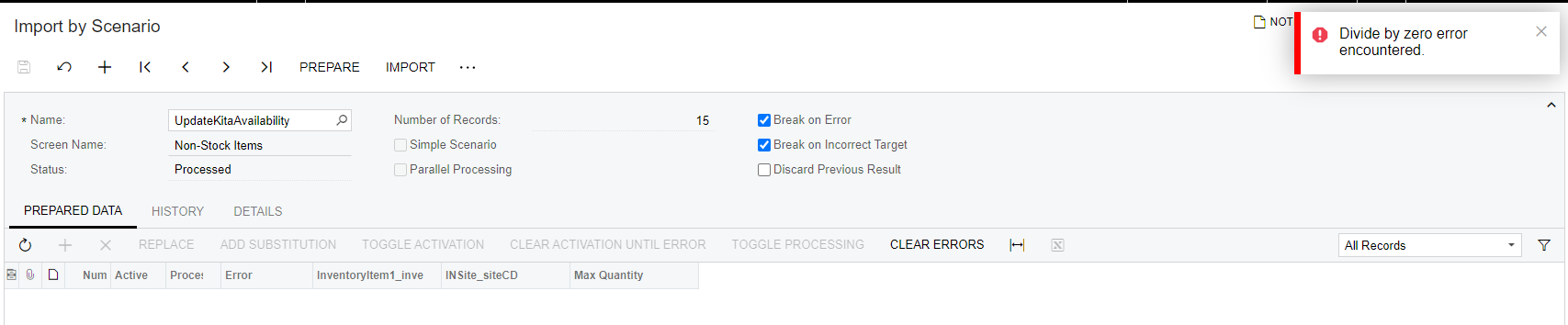

Screenshot from the import scenario :

Commerce connector use: The import scenario will show/hide the non-stock kit based on the availability using the formula in the above screenshot

“=IIf( [InventoryItem_Formulaffdc1a6b00e64948bf4b9f59d7eb191d]>0, 'Store Default', 'Set as Unavailable' )”

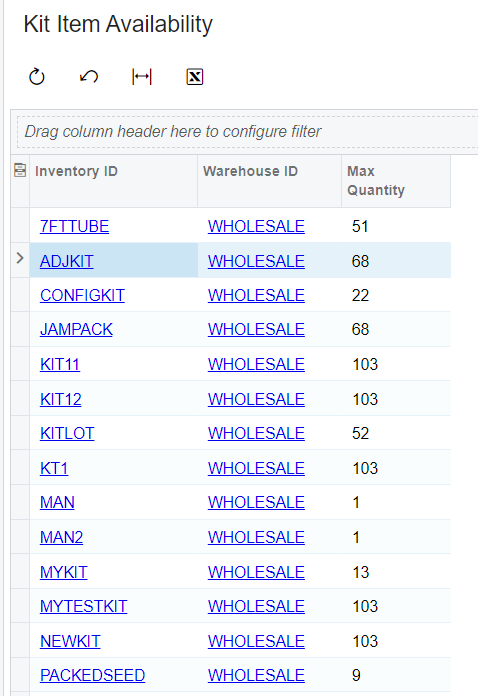

Screenshot from the GI results