Does anyone have any ideas on how to add backordered items to an Invoice? These would be zero dollar lines for visibility purposes only.

We have the Add Zero Lines for Items Not in Stock checkbox checked on the Sales Orders Preferences (SO101000) screen so we get the following behavior:

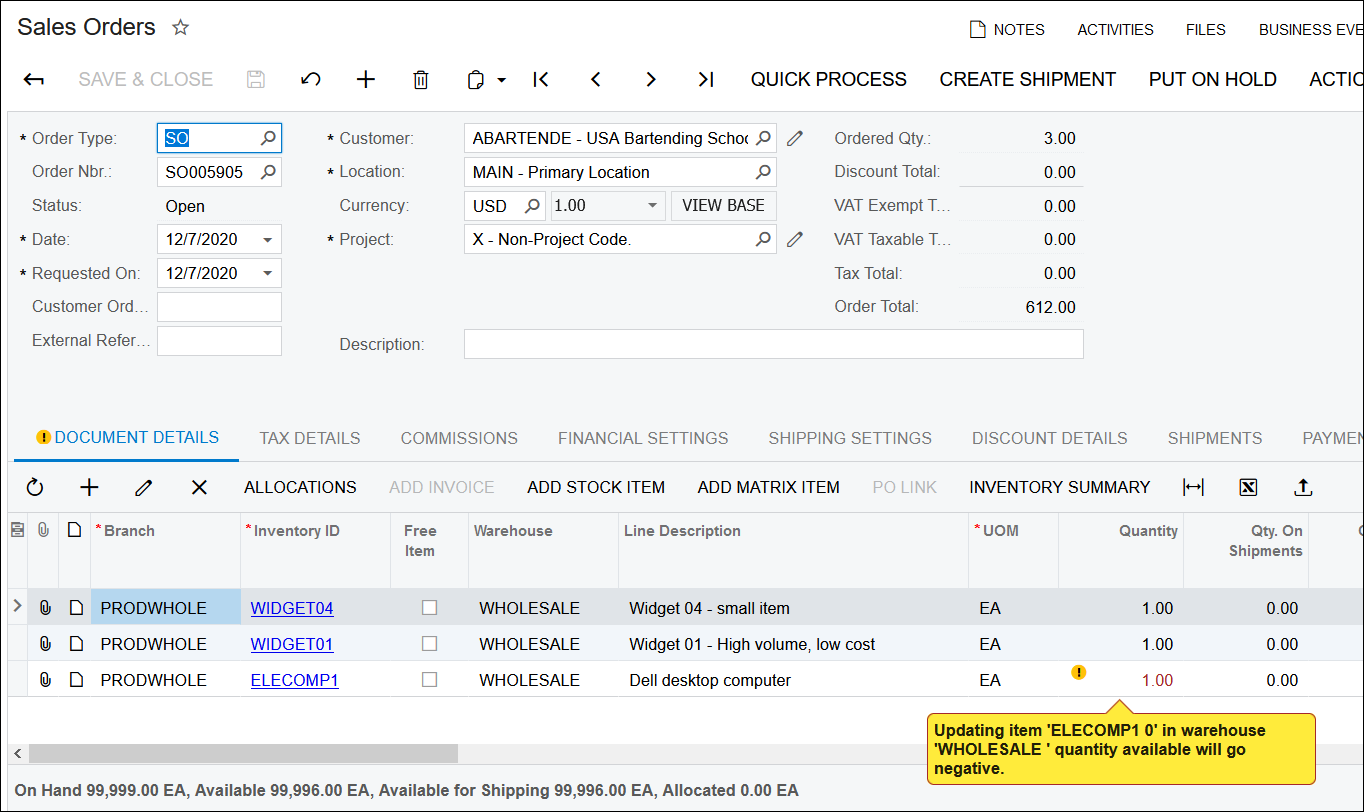

1. Create a Sales Order where the first 2 lines are available, but the 3rd line is not available:

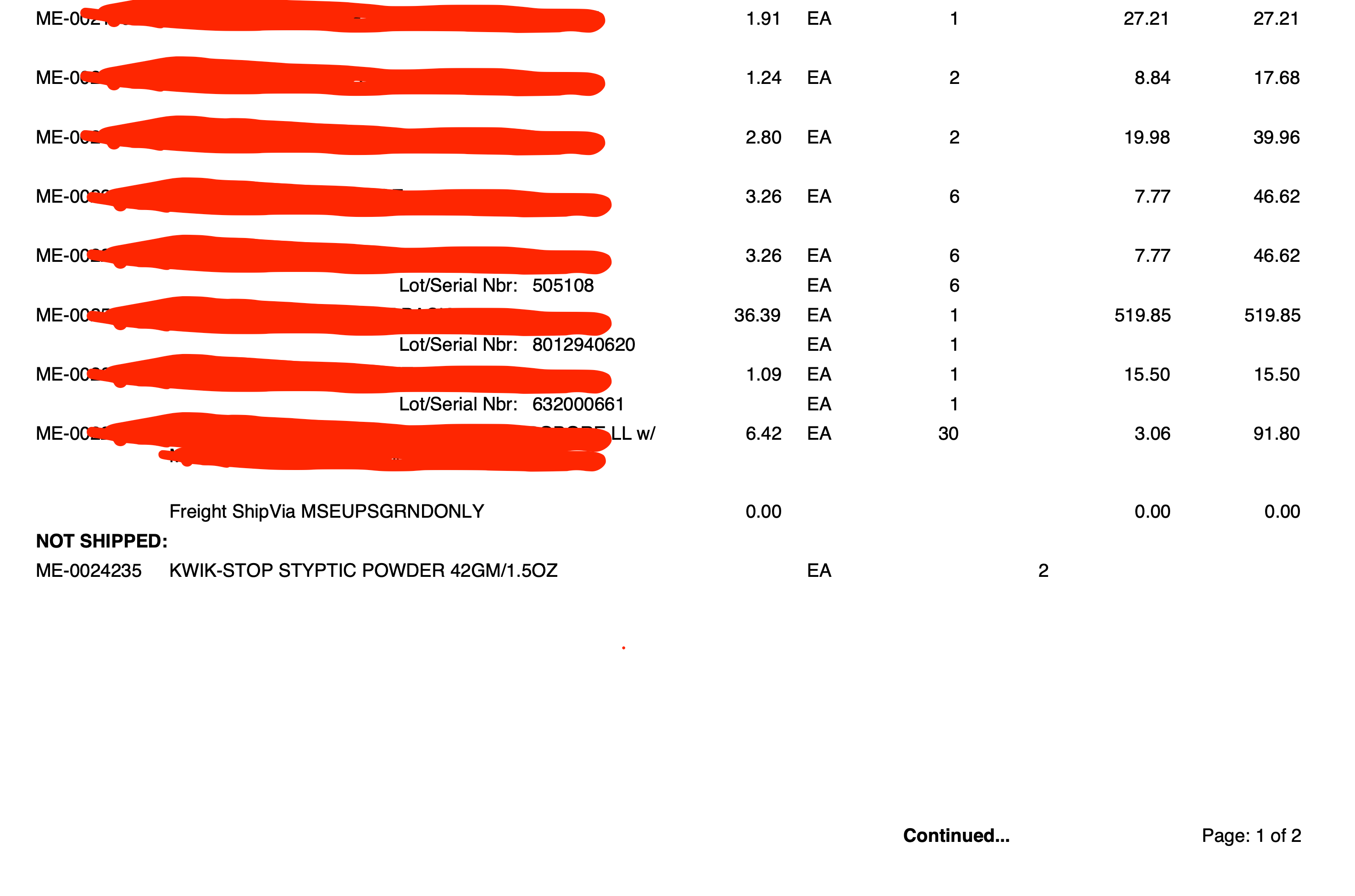

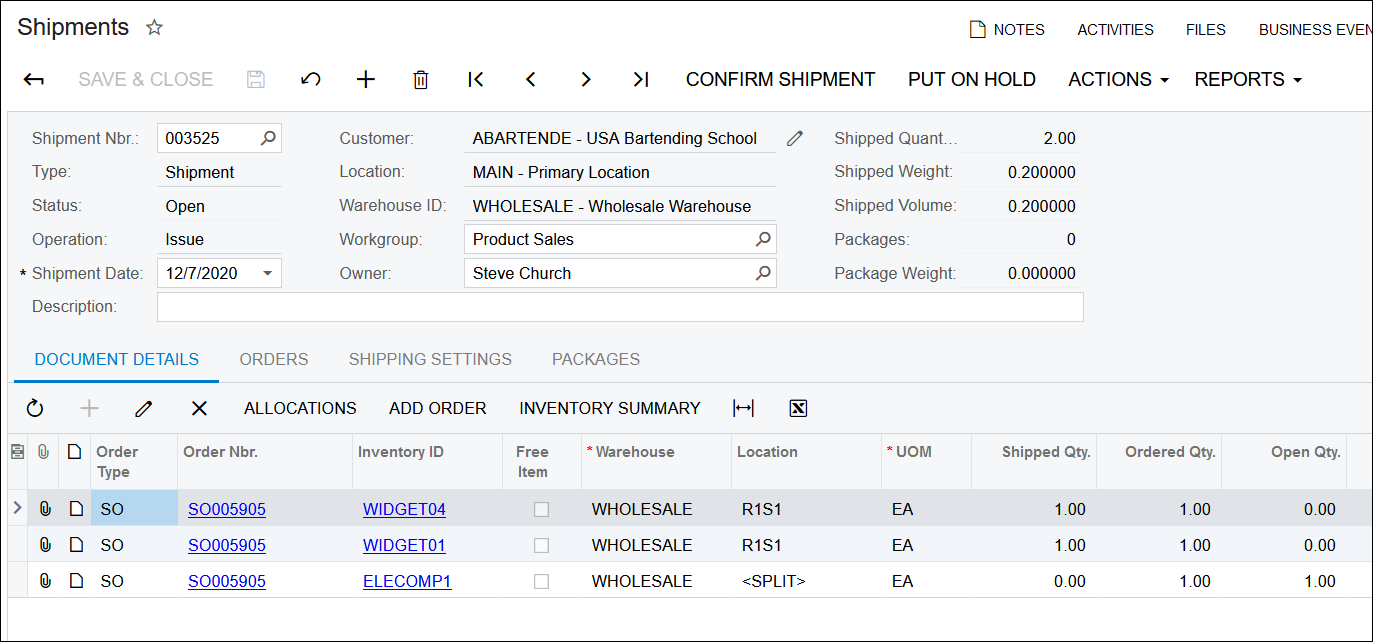

2. Create a Shipment and all three lines are carried onto the Shipment, even though the 3rd line is not shipped:

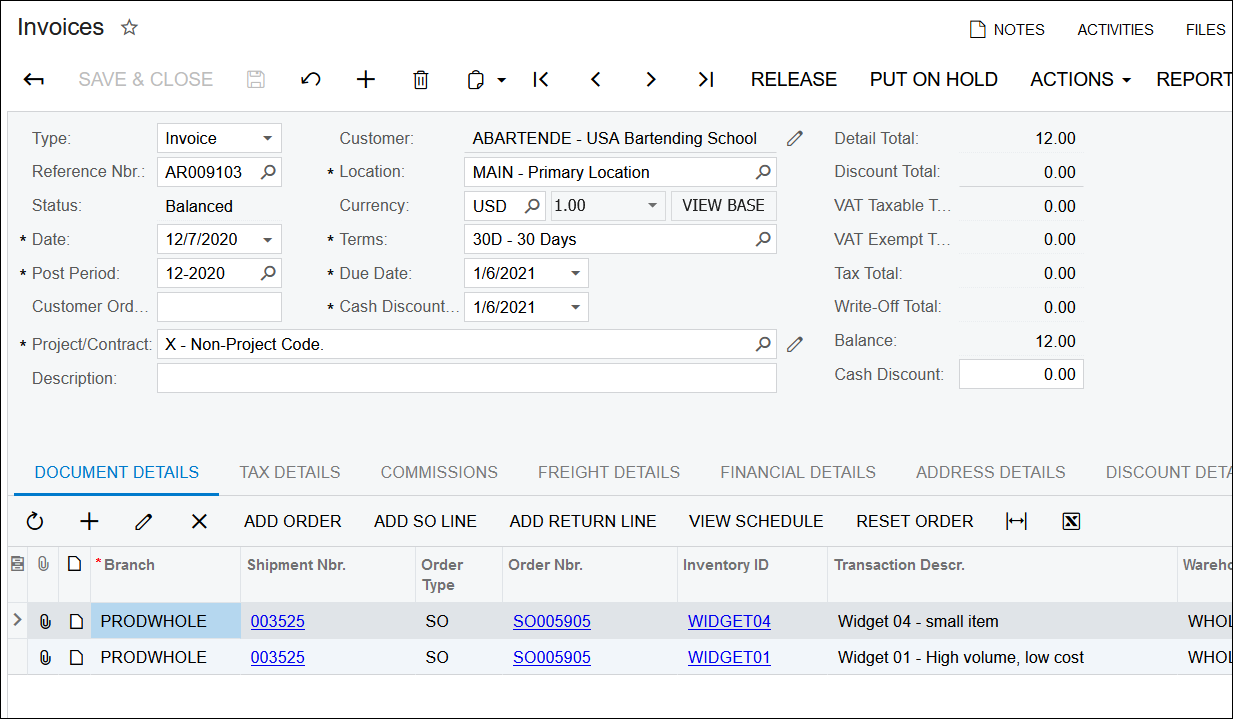

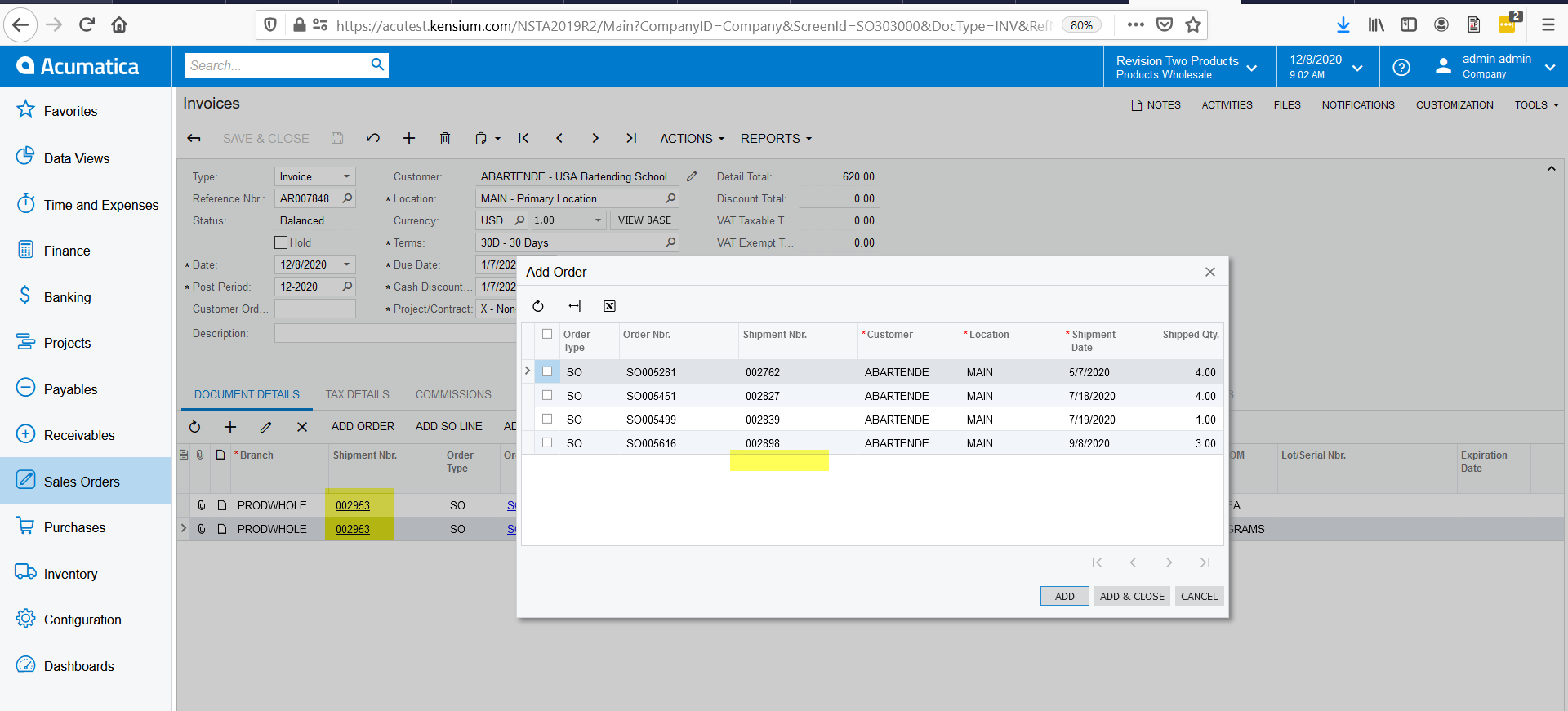

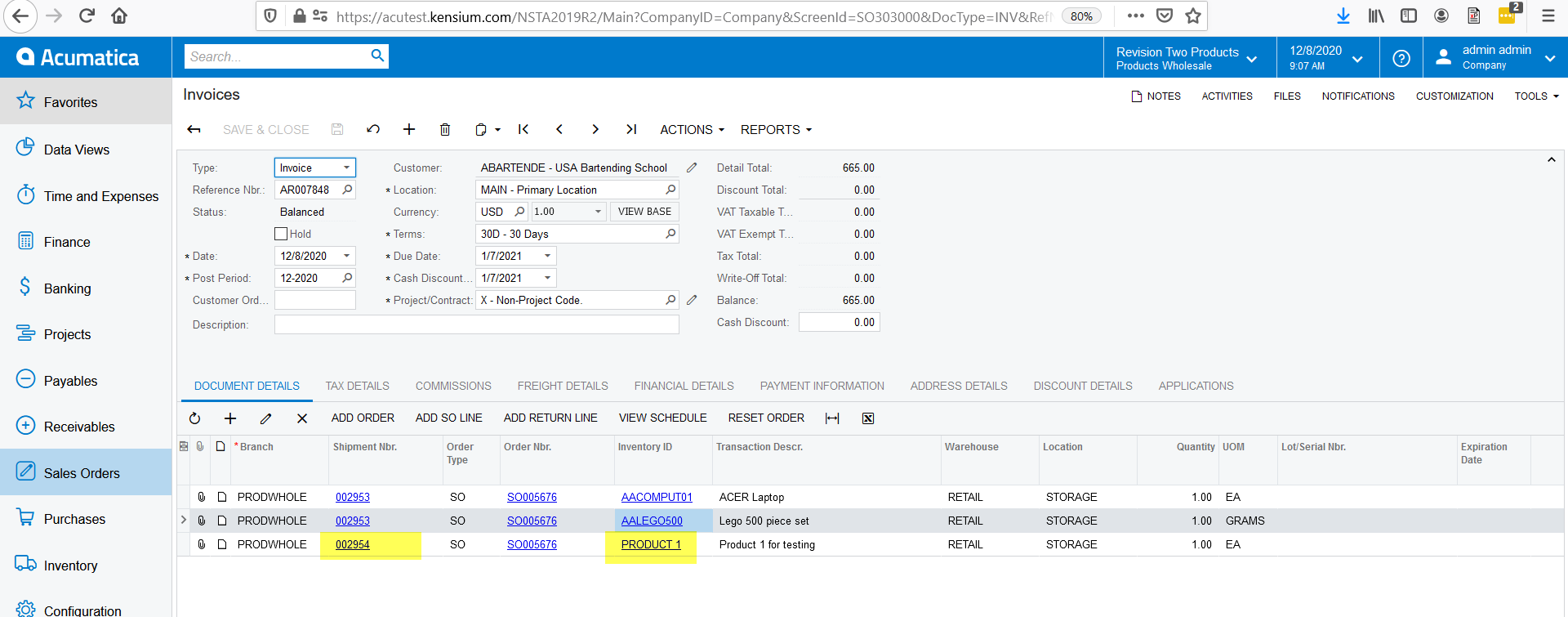

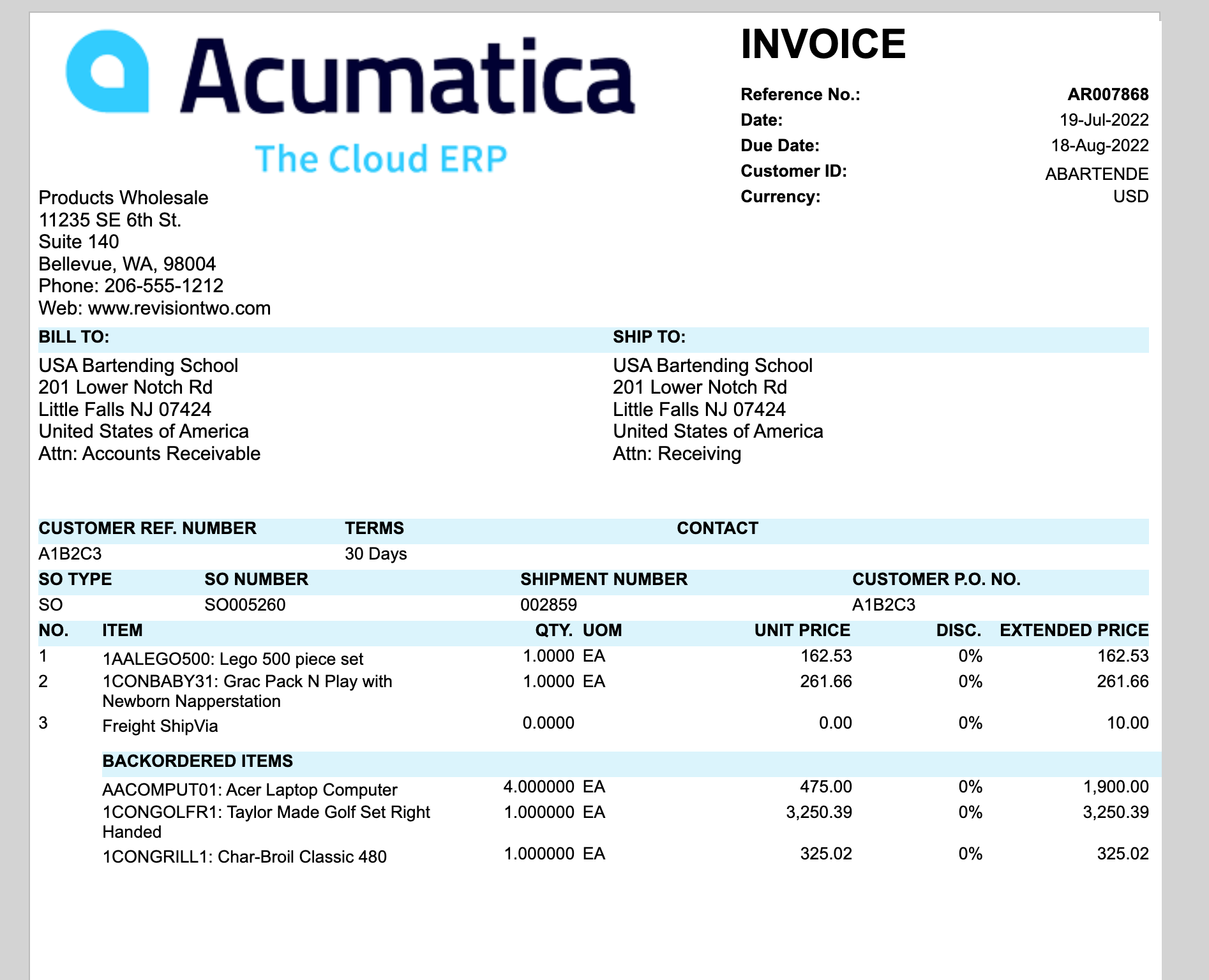

3. Create an Invoice and only the first two lines are carried over. The 3rd line disappears since it didn’t ship: