Hi everyone,

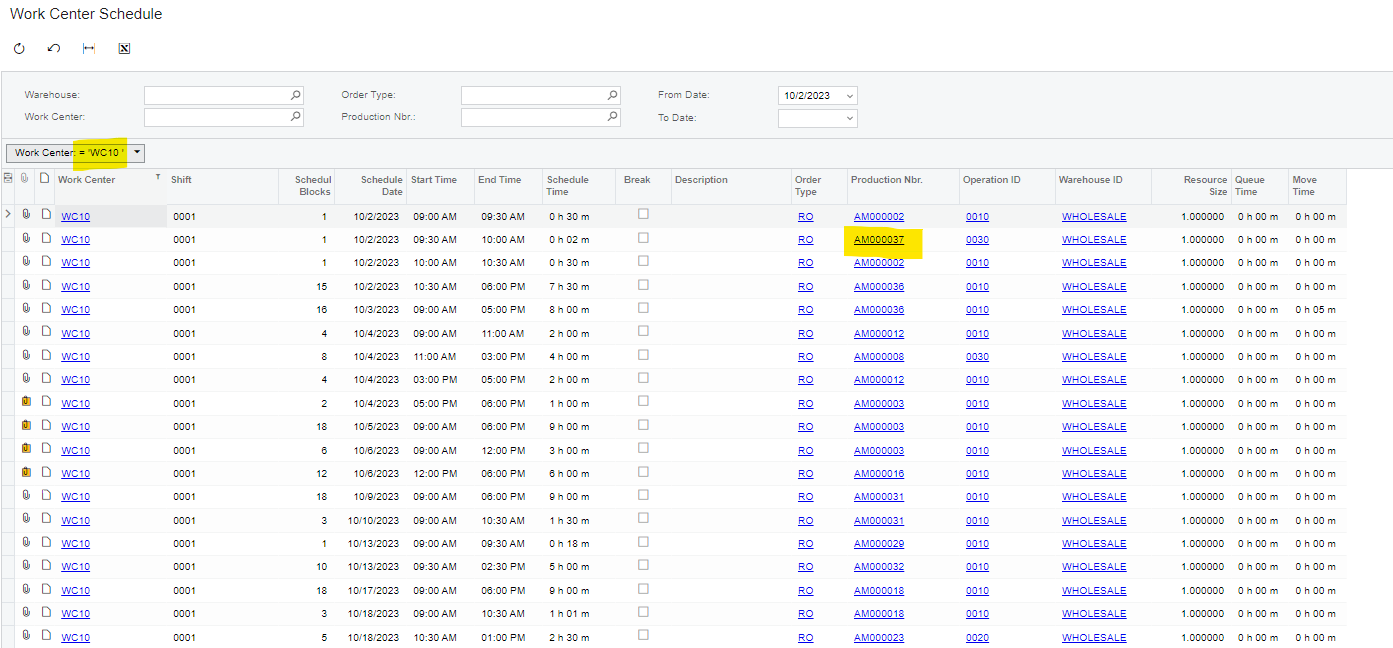

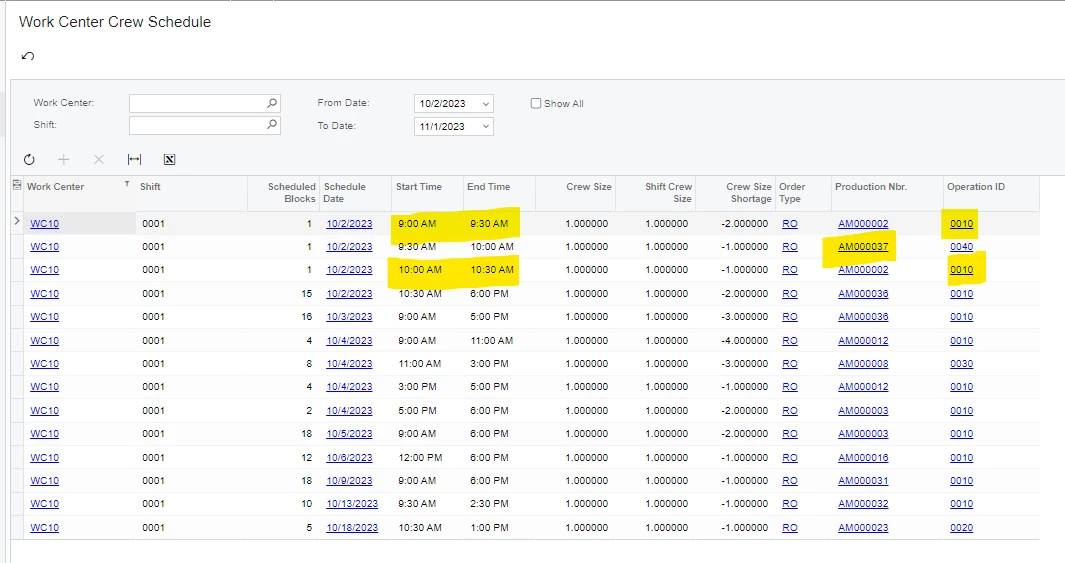

Is anyone able to explain the reasoning for why after Rought Cut Planning is processed, that the system is slotting in AM0000037 in between 2 blocks of AM000002. I would expect the system to block of 2 “30 minute” blocks to complete operation ID 0010 for AM000002 entirely before starting another Production Order.

If i update the crew size to 2, in the WC10, it of course completes the entire operation in 1 block.

We are trying to understand what system logic, system preferences are causing the AM0000037 Production order to be slotted in-between.