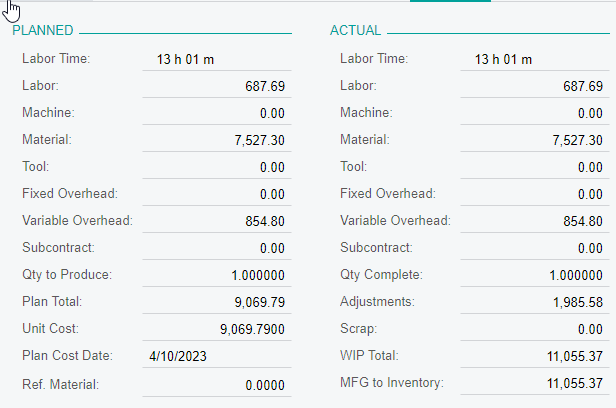

I was hoping someone may have some insight to this question. I am coming up with a large WIP variance in our Production Orders, and are thinking Phantom BOMs might be the cause.

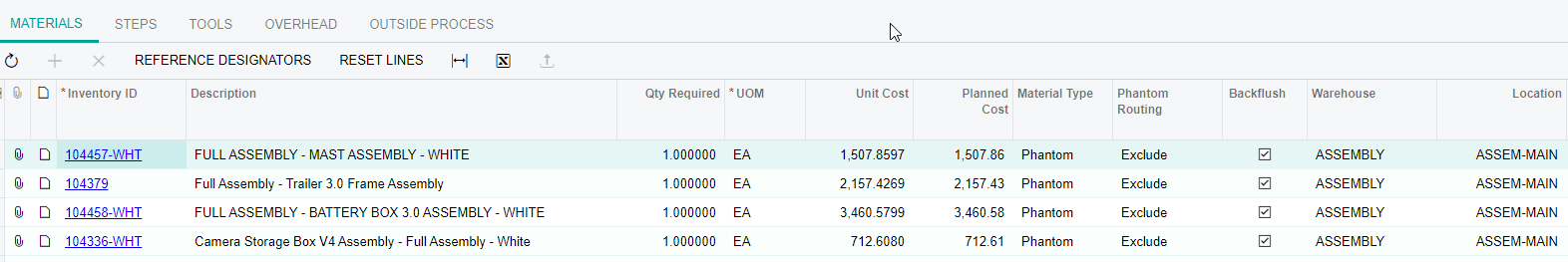

At the parent level, we backflush material and labor. We also exclude the Phantom, thus allowing us to bypass the move in the production order.

At the BOM for the phantom, we have run rates as if we were going to make a Production Order and backflush labor and material.

Is the WIP variance related to excluding the phantom and thus not capturing the labor?