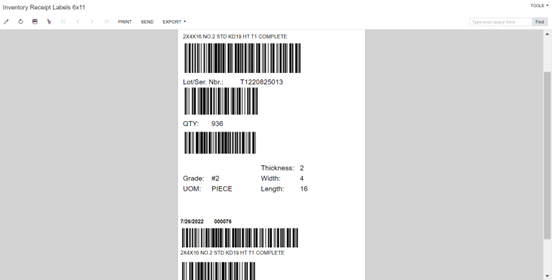

We produce labels for our subassemblies based on inventory receipts that are generated in the production process. This has worked well for us in the past as we have only ever manufactured in singular large lots based on the production process. Below is an example of a label that produced 936 pieces of wood.

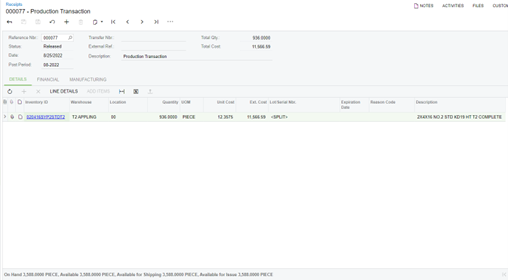

However we are now generating multiple lots from singular production orders (EX: 6 lots of 156 pieces) which is causing the lots to pull in as <split>. This is because the lots have been pushed to the line details tab as there are multiple for a single line. Please see example below.

Now the barcodes will not generate on the labels because it pulls directly from the receipt page.

There are two possible solutions for this, neither of which I am sure how to execute:

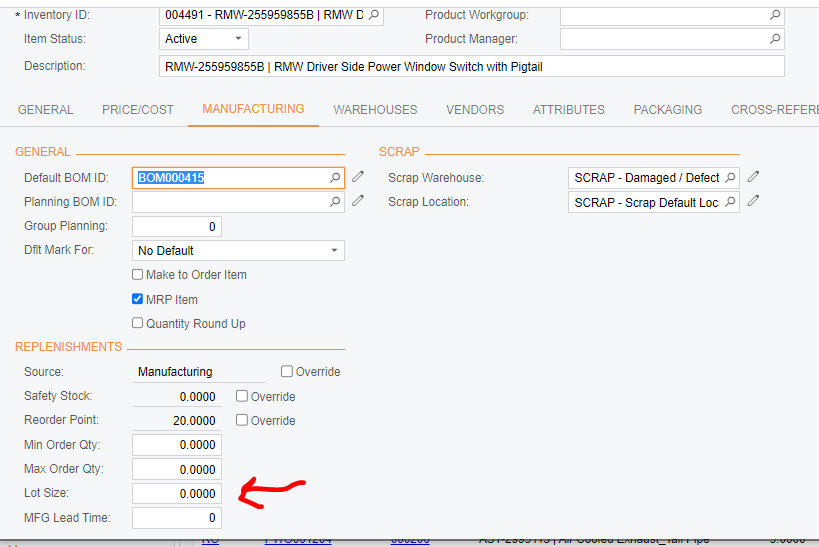

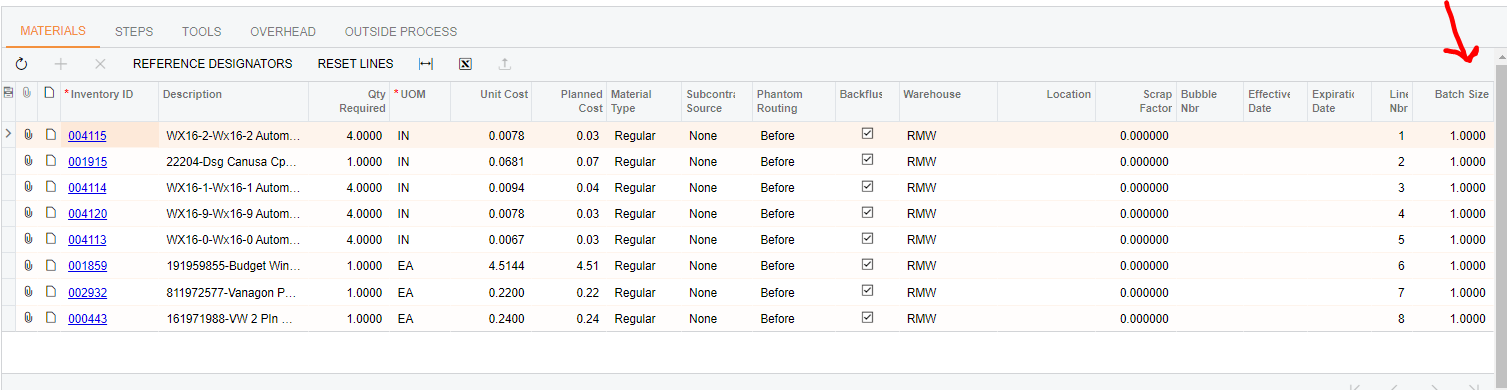

- If we could specify in the production order that we’d like to generate 6 lots of 156 pieces so that they would appear that way on the on the receipt, then there would be no problem. However, I have found nothing that specifies lot sizes for production.

- If I could format my barcodes properly in report design to say something to the effect of “If lot = split, then pull lots from line details”. However I am not that savvy with report designer just yet to assess that possibility. The syntax for the barcodes in report designer is a simple =[INTran.LotSerialNbr].

Does anyone have any solutions. Any assistance would be greatly appreciated!