I would like to code some actions that I can do manually:

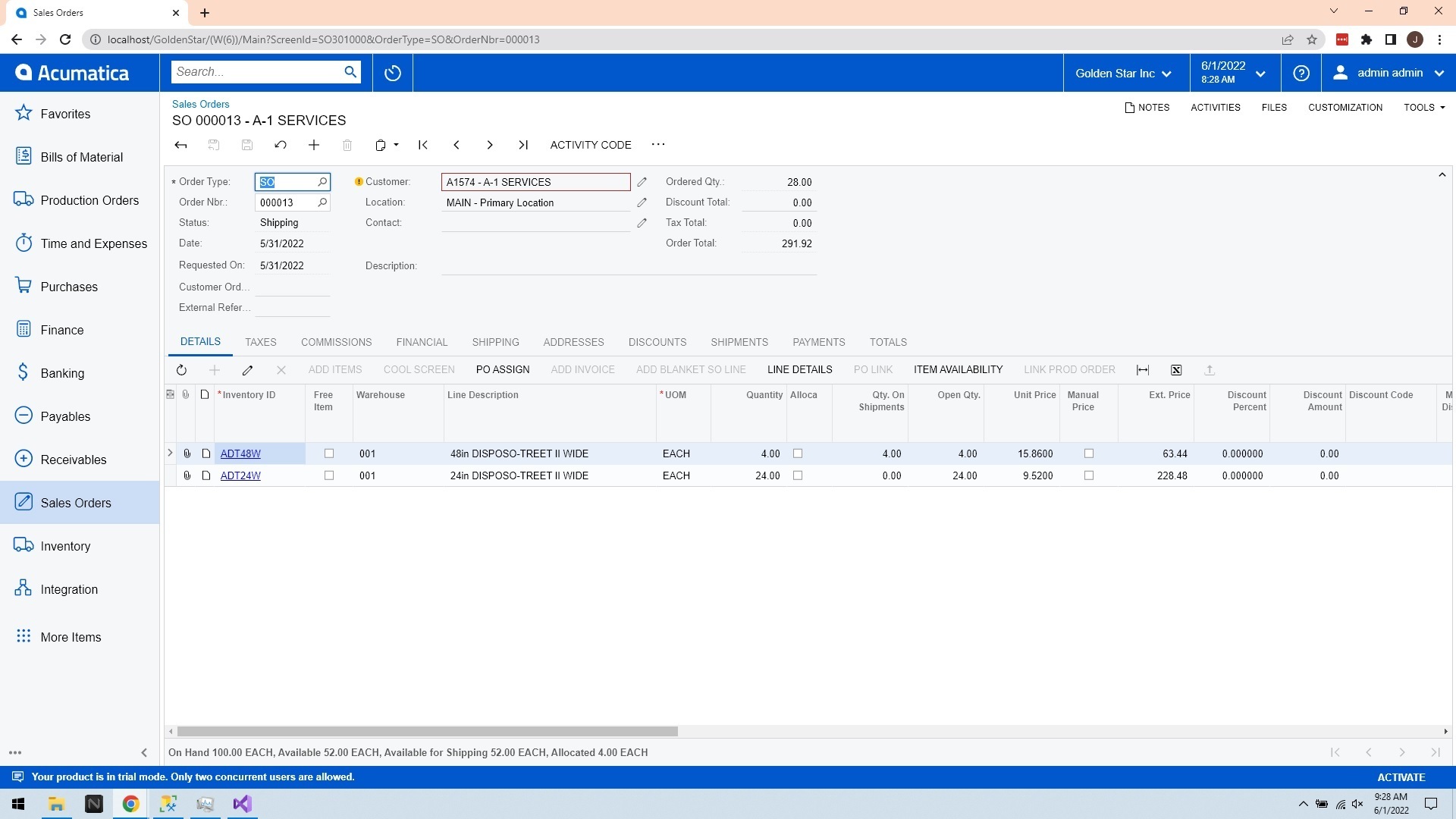

- I have a sales order with two line items

- for one item a shipment was created.

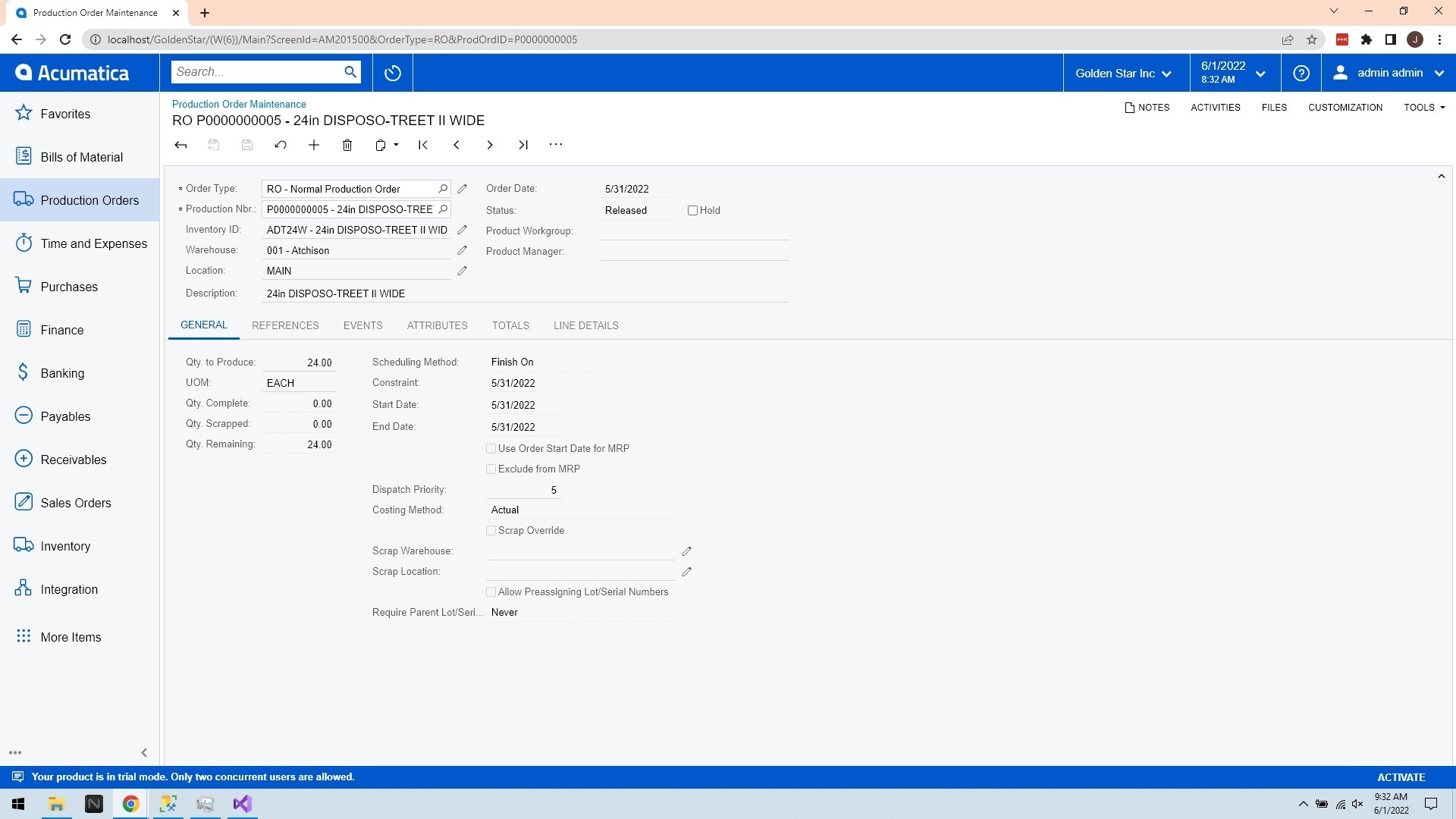

- for the other item a production order was created

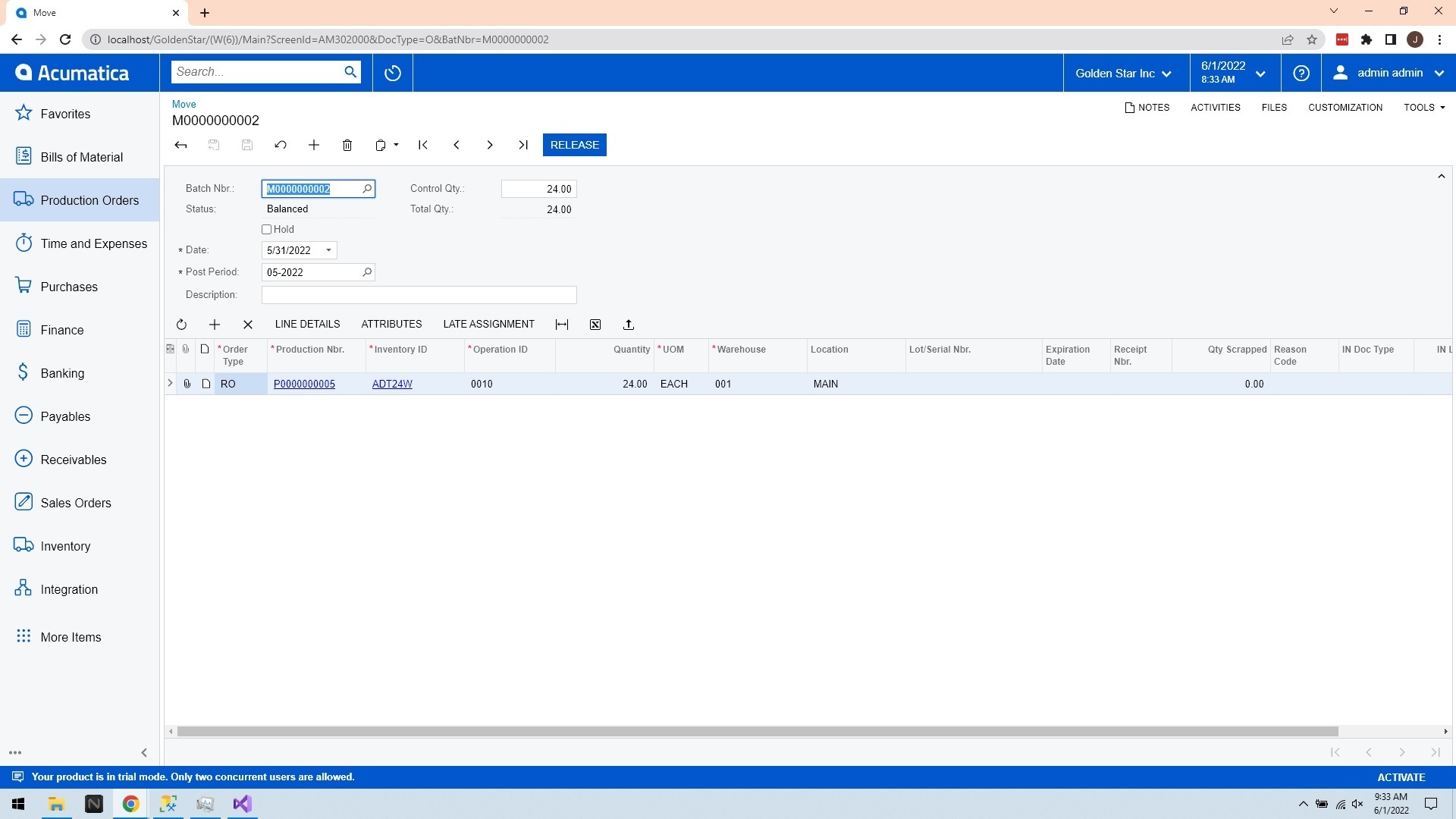

- the production order was completed and a move transaction was created

- Upon the “release” of the move transaction, I would like the below to occur via code:

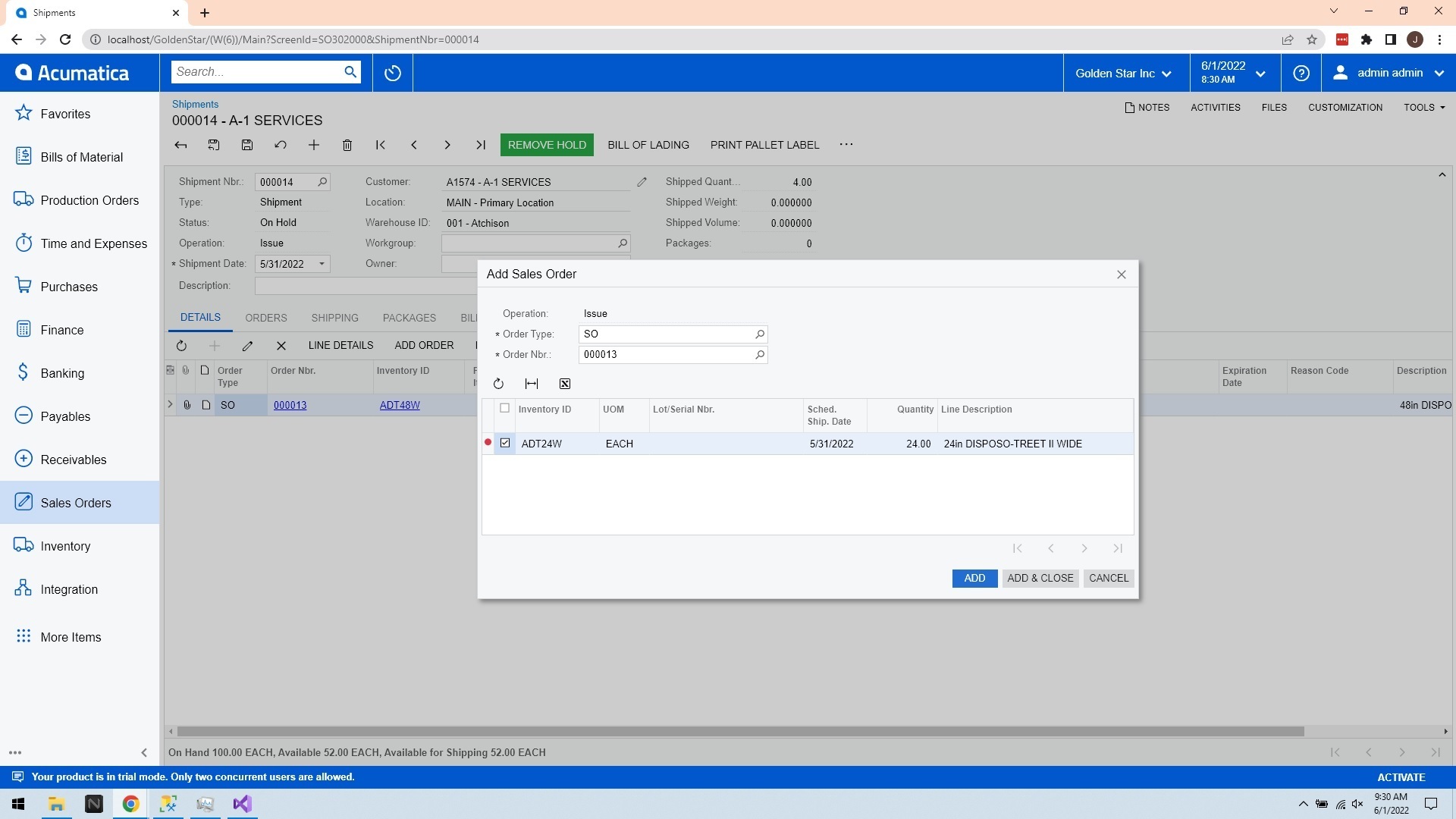

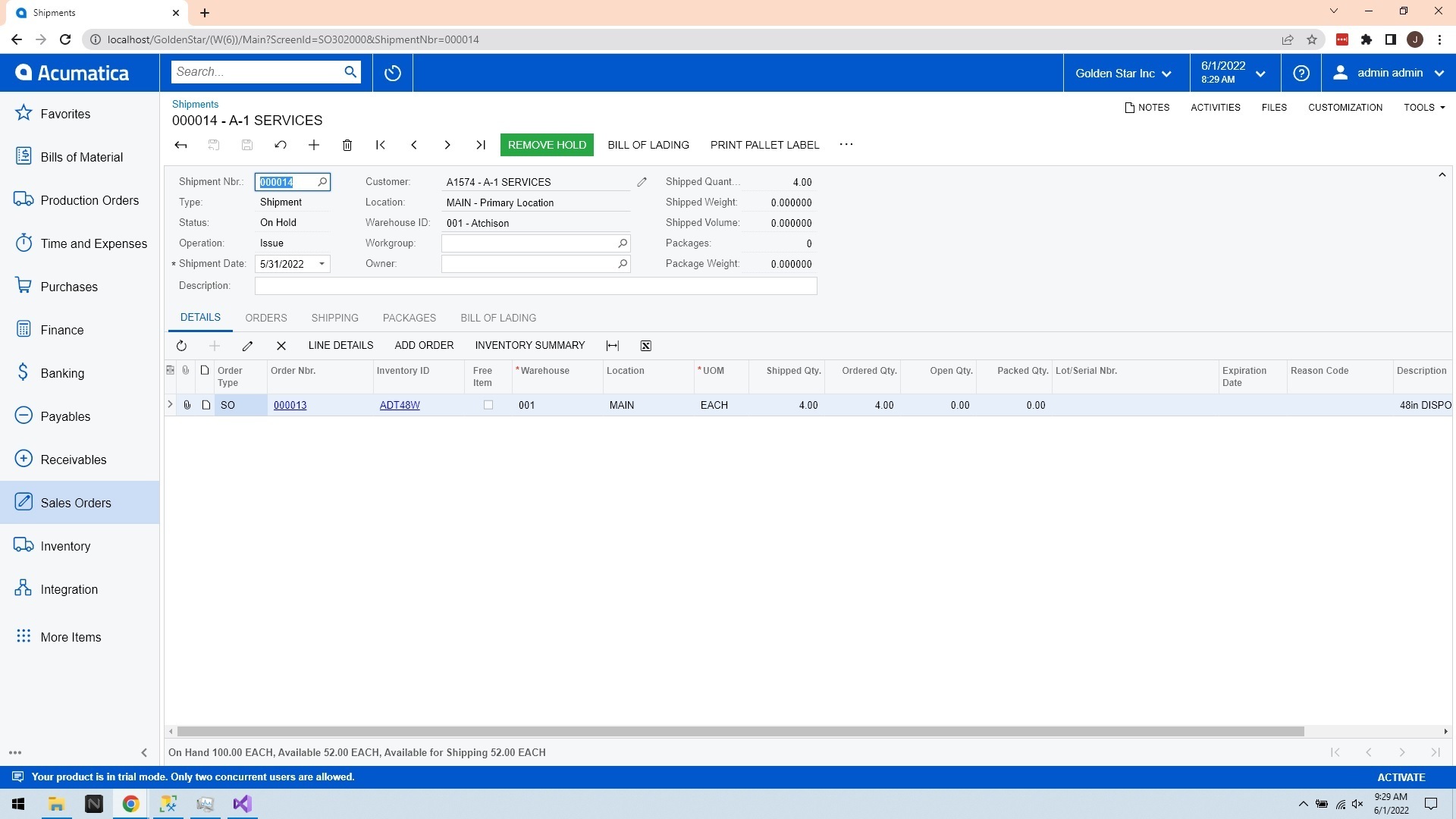

- shipment screen; existing shipment for SO; “add order” dialog; select InventoryID that was just released from the “release”; click “add button”

I’ve been able to override the move/release button (below) but have no idea what code to write for the actual functionality.

public IEnumerable Release(PXAdapter adapter, ReleaseDelegate baseMethod)

{

var baseReturn = baseMethod(adapter);

var prodLines = Base.transactions.Select().RowCast<AMMTran>();

foreach (var prodLine in prodLines)

{

// TODO: code to add to shipment

}

return baseReturn;

}