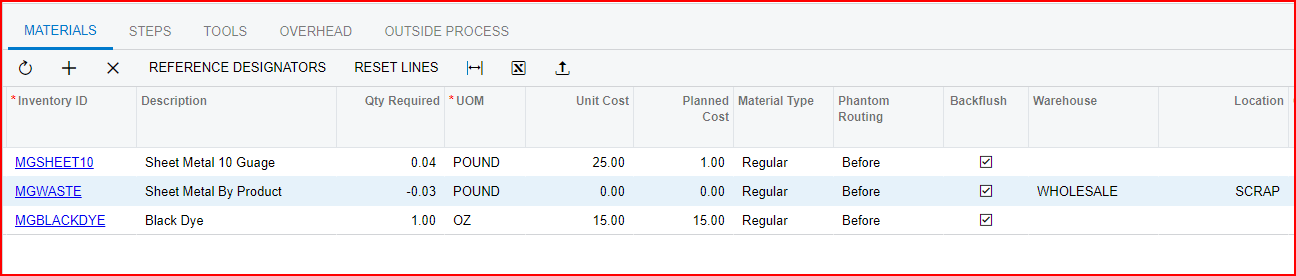

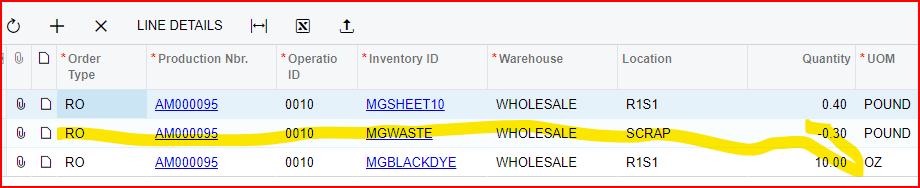

I am having a difficult time recording production waste from a raw material input. In a BOM I have configured, it takes 3lbs of an item for a yield of 1.95lbs. I set this up in the BOM material line item indicating that 1.95lbs are required with a scrap factor of 0.538462 so that a total of 3lbs is removed from inventory. I set up a production reason code and in the Work Center and BOM I set scrap action to Write Off. The raw material is a lot tracked item, so I issue the material and I see 3lbs removed from inventory and go into WIP. When I perform the move transaction, the cost of 3lbs is moved into inventory when only 1.95lbs should be in inventory with 1.05lbs written off. I have also tried changing the settings to quarantine and set a scrap warehouse and location (set up in the order type and stock item (but I cannot get that to work wither. This is not the produced product that is waste...it is one of the input materials so I cannot specify a scrap amount on the move transaction as this would be quite cumbersome for the client to have to calculate based on various production run quantities. Lastly, this client eventually sells the waste as it has substantial value.

Any insight as to what I am doing wrong?