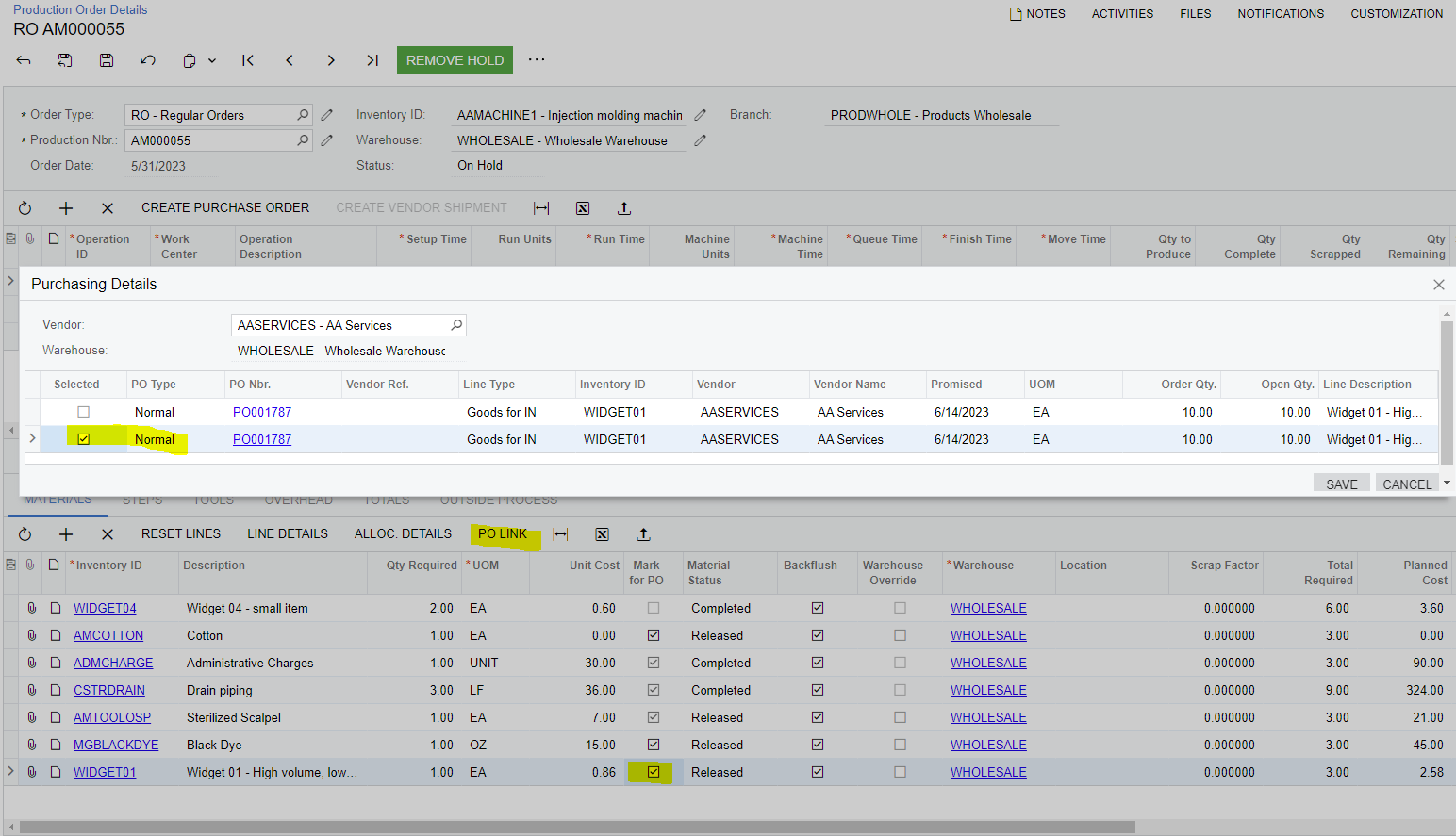

This is related to blanket sales orders. Customer places an order for 500 widgets to be shipped out 50 pcs per month. Our production process is optimized to make 50 widgets on each production order timed to the desired ship dates. We can create 10 production orders and then create POs from the 10 production orders, but we get better pricing on the raw materials if we combine the POs and make one bulk purchase.

Is there a good way to do this? We have tried creating a production order for the entire 500 pieces and creating the PO from that Production order, but then we need to create the actual production orders for 50 pieces that the materials will be issued to. It get confusing because the materials are issued to production orders that are not the production order the materials were purchased for.