Im trying to think of a creative way to get around an issue we currently have, we’re implementing having sales order confirmations as we load a customers order, but a range of products that we make show up on Back Order.

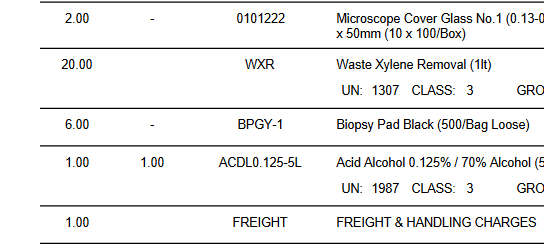

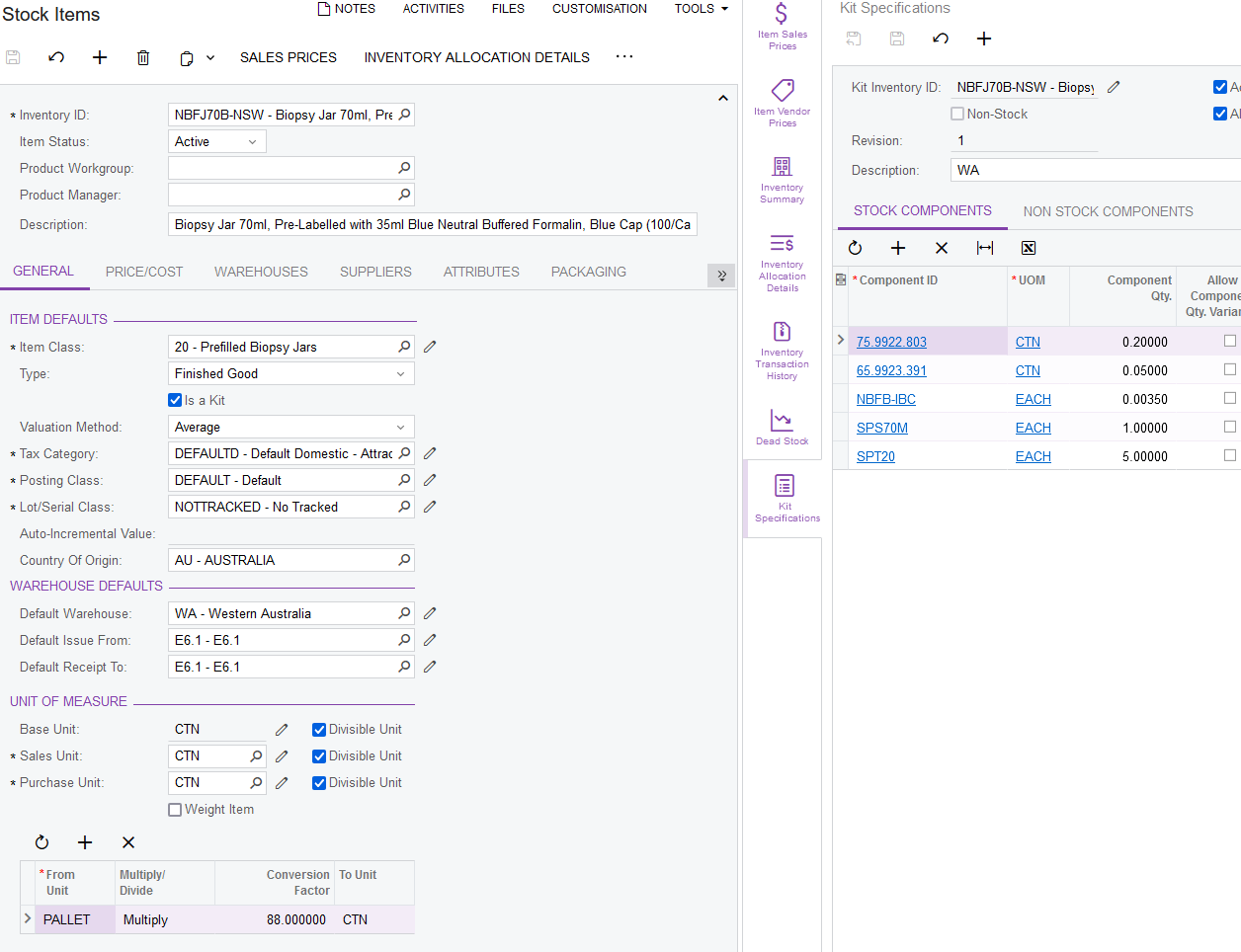

To take a step back, its mainly things we have to either make or decant. For example, 5L of alcohol. We store it in 1000lt tanks, decant as needed. This is a specific for a lot of stains for pathology use. Internally we send a copy of this to the warehouse or lab to be made, then kit assembly to build the item > create shipment ready for a picking slip.

There could be a delay here though, sometimes a few hours, sometimes a day or two.

Very rarely do they actually goto back order by the time the sales order is invoiced. Majority of the items where it would happen are critical to the order the customer is placing, I don’t want them thinking there is a delay with these products. But I don’t want to confuse all customers with a disclaimer in the body of the email sending the sales order confirmation as there are plenty of genuine BO’s.

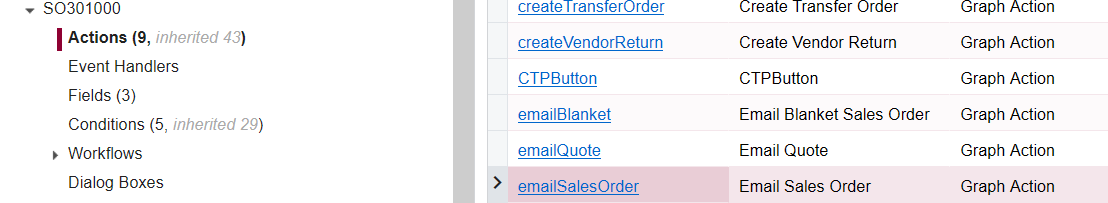

Any idea’s here? Is there a filter i can add on the Report for SalesOrderConfirmation to not show a group of products using an attribute? I thought of just using shipment confirmations, but they don’t display Backorders. SO any items that are backorder would look like its being missed off the order.

Curious if anyone has had a similar issue or a suggestion that im not thinking of.