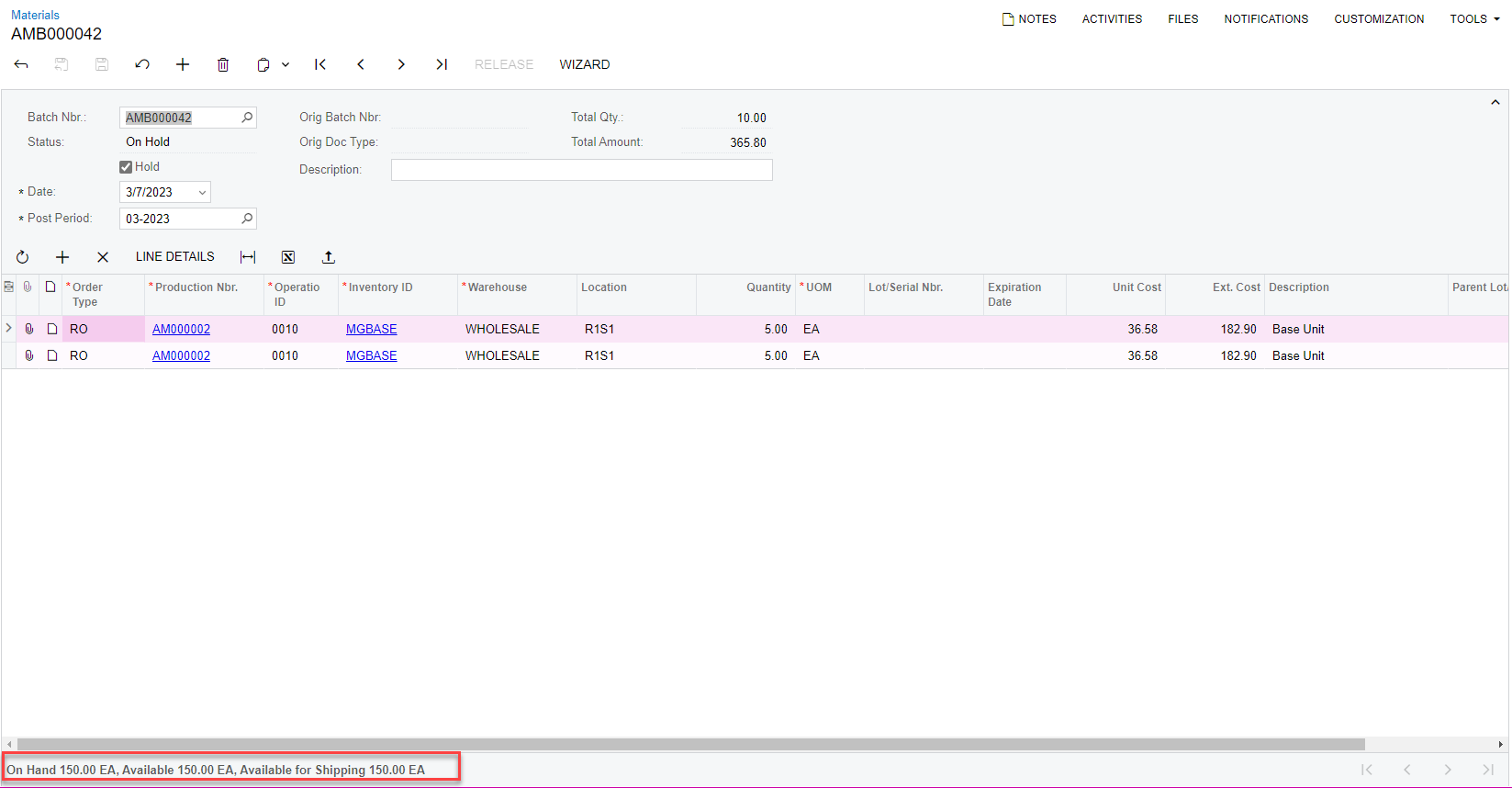

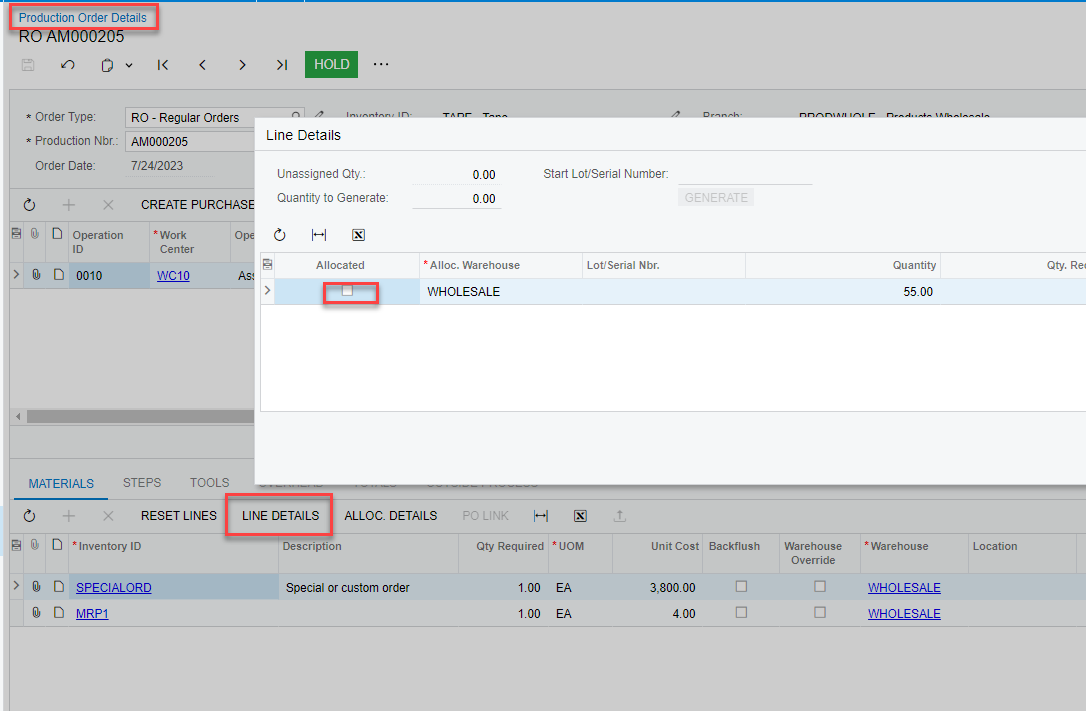

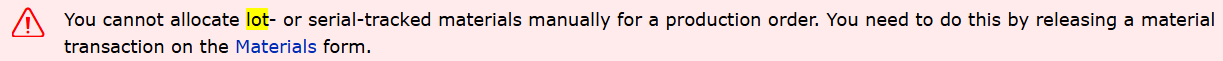

Im sure this has been asked, but I can not find it. I need to know where to allocate material for production orders. We are running into issues where not all materials are in for all orders, but enough is in for some. and the production floor doesn’t know what they can and cant fill, then material gets pulled for orders that are not components complete. example we have 1 product for 5 orders.1,2,3,4,5 we have everything for orders 2 and 5, and I want to allocate that material to those production orders.

thanks!