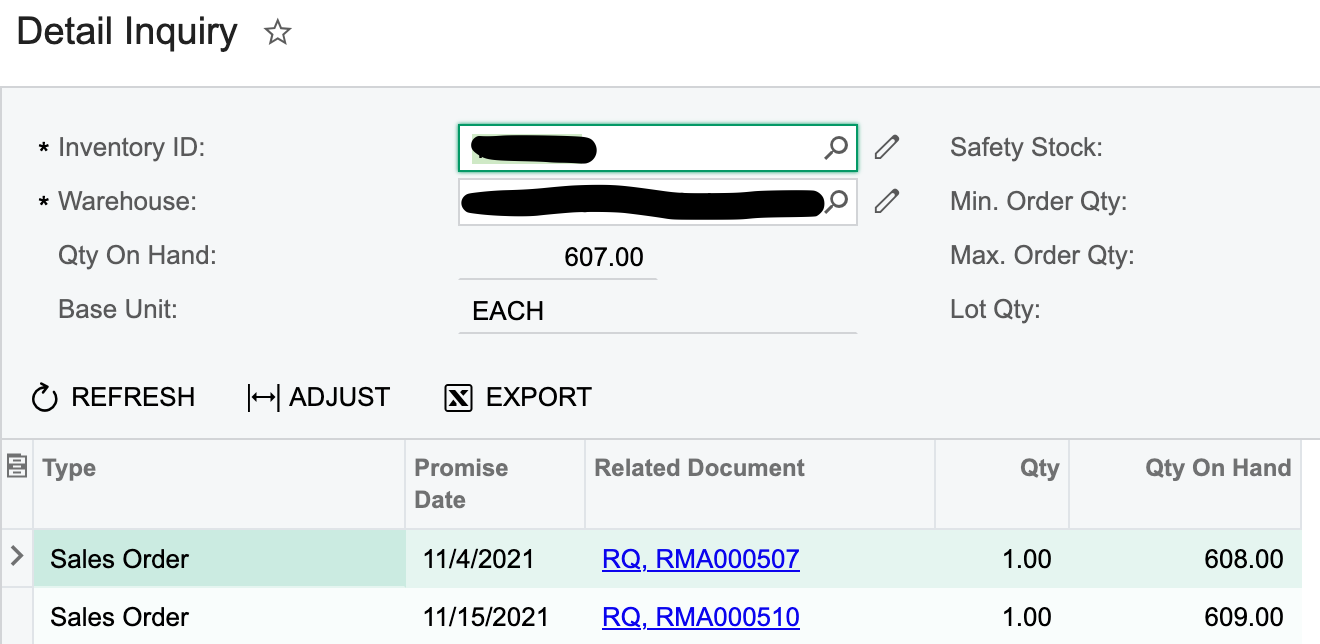

When I have an open RMA order for stock items - MRP states we will be receiving the items as supply that will satisfy demand. This is not appropriate since the materials must pass through quality inspection and disposition.

How can I remove RMA receipt material from being viewed as a supply signal in MRP?