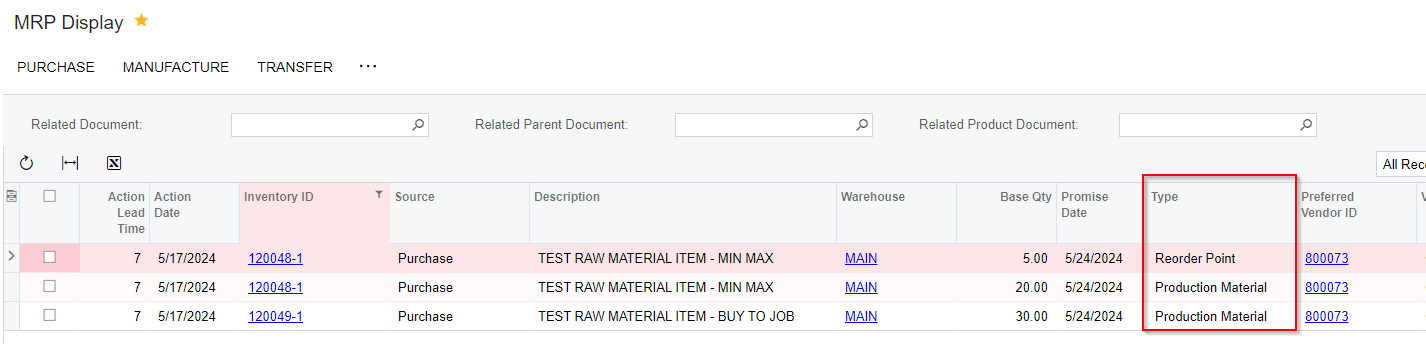

I have a question on MRP Types. I have certain stock items that are managed on a min/max basis. Screws, for example, I just want to maintain an inventory level but don’t really care which unit of production they go in to. The screws are on the BOM, so when I run MRP these items show up to purchase twice. One purchase suggestion is triggered by the Reorder Point, which is what I want. However, another purchase suggestion is triggered by Production Material, which I don’t want.

Is there a setting within the Stock Item or possibly MRP Preferences that allows me to only use Reorder Point for MRP and not Production demand for items with a Min/Max replenishment method?