We are currently trying to change the scrap percentage of a component which exists in thousands of parts, and it looks like the Mass Change function in Bills Of Materials work space is limited to only replace one part for another. I was hoping there would be something that we could make a change to any field that exists in the BOM for a component and be able to reload to Acumatica.

There is nothing in the standard product yet to facilitate this change.

I believe most companies utilize the import / export scenarios to make these changes.

Thank you.

Hi

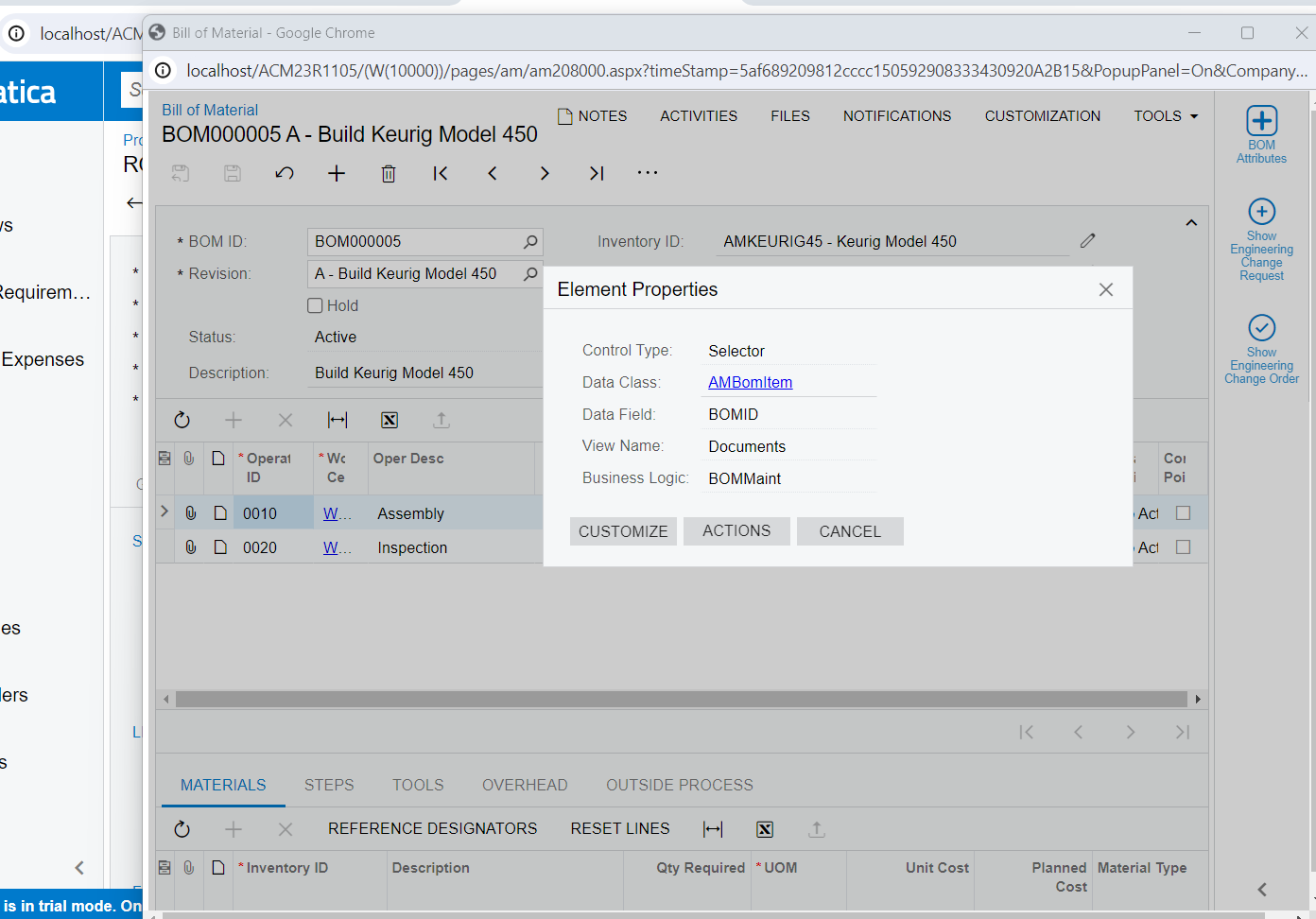

- Try creating a Generic Inquiry for the table AMBOMItem (Shown below)

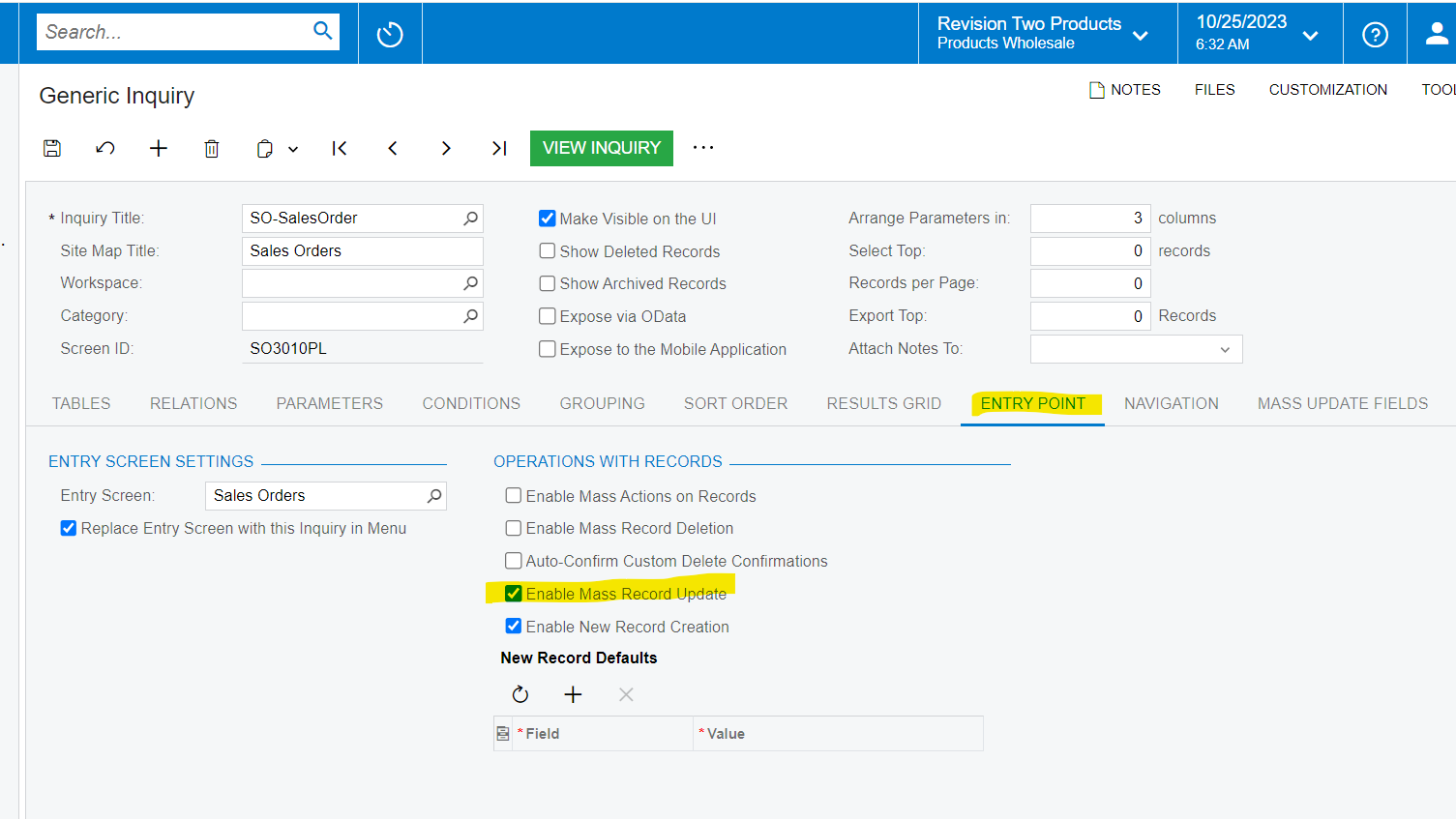

- Configure the generic Inquiry to have mass Update option. Teh configuration is available in the “Entry Point” tab.

Note: for quick reply, I have used the SOOrder generic inquiry to provide you the workaround. Let me know if you need more support.

Sample Screenshot:

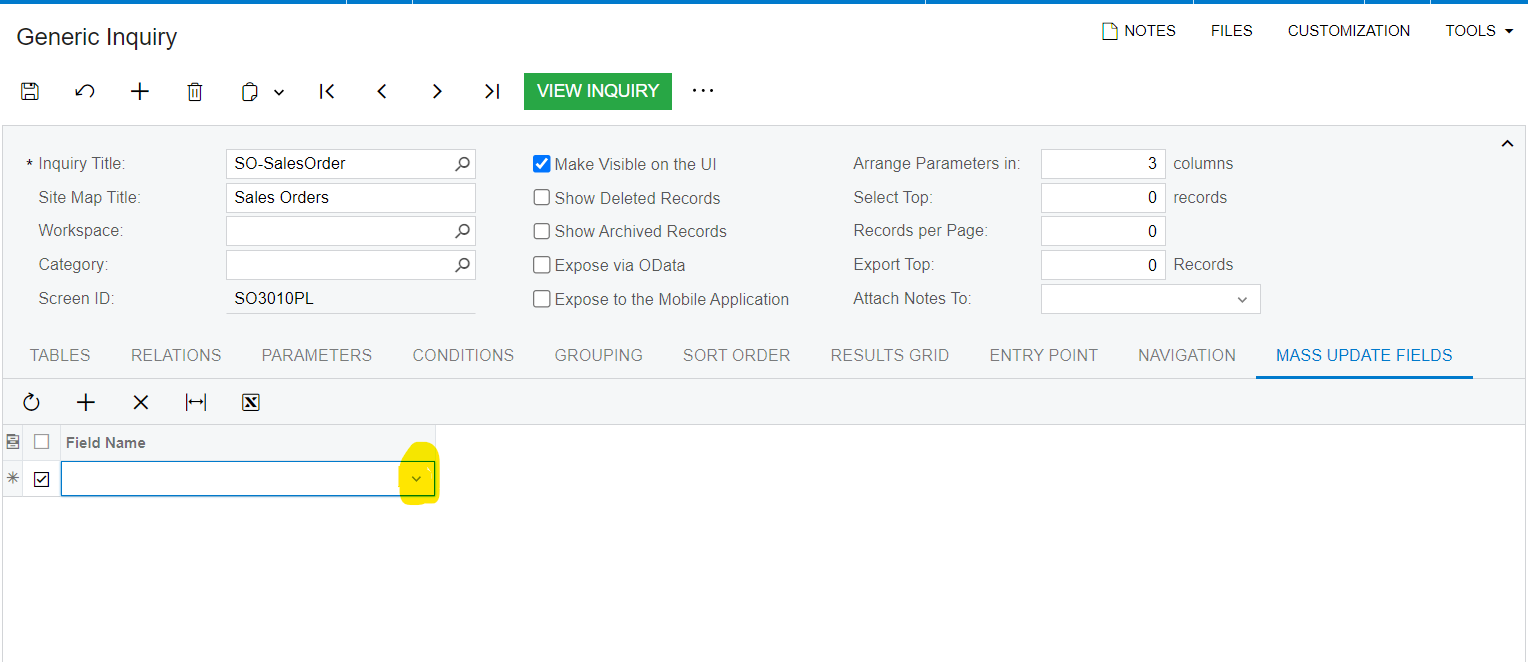

- Add the fields to Update

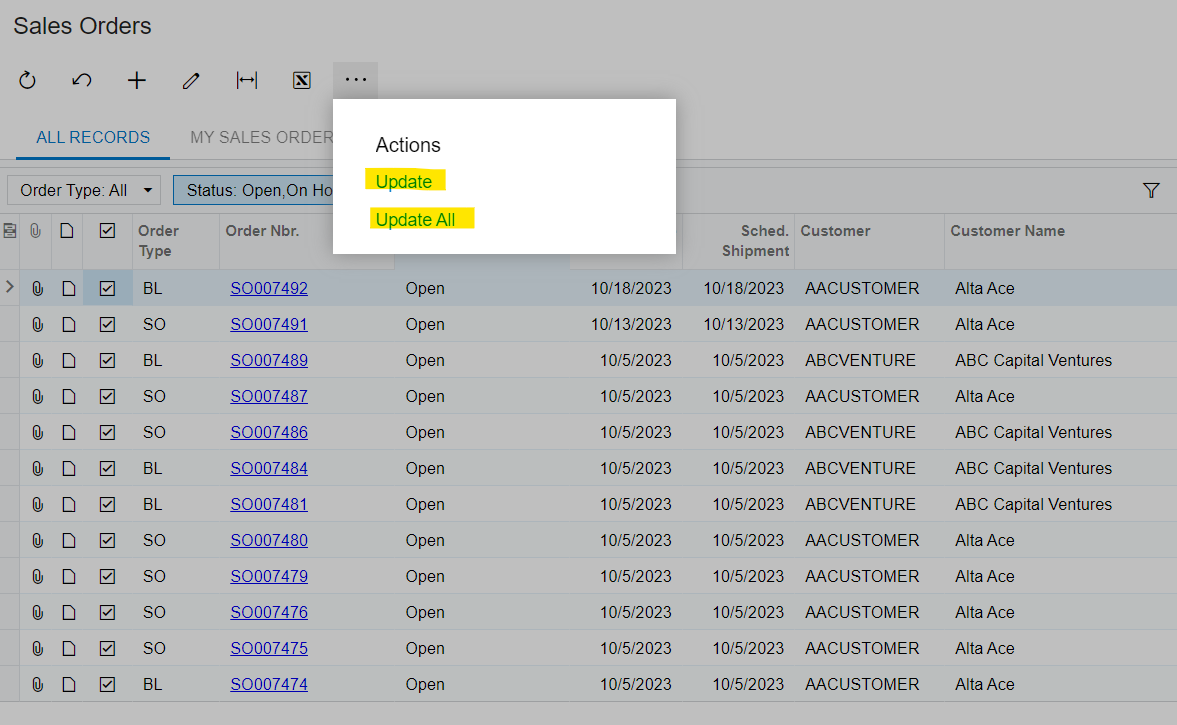

- View Inquiry on the generic Inquiry to see how it works::

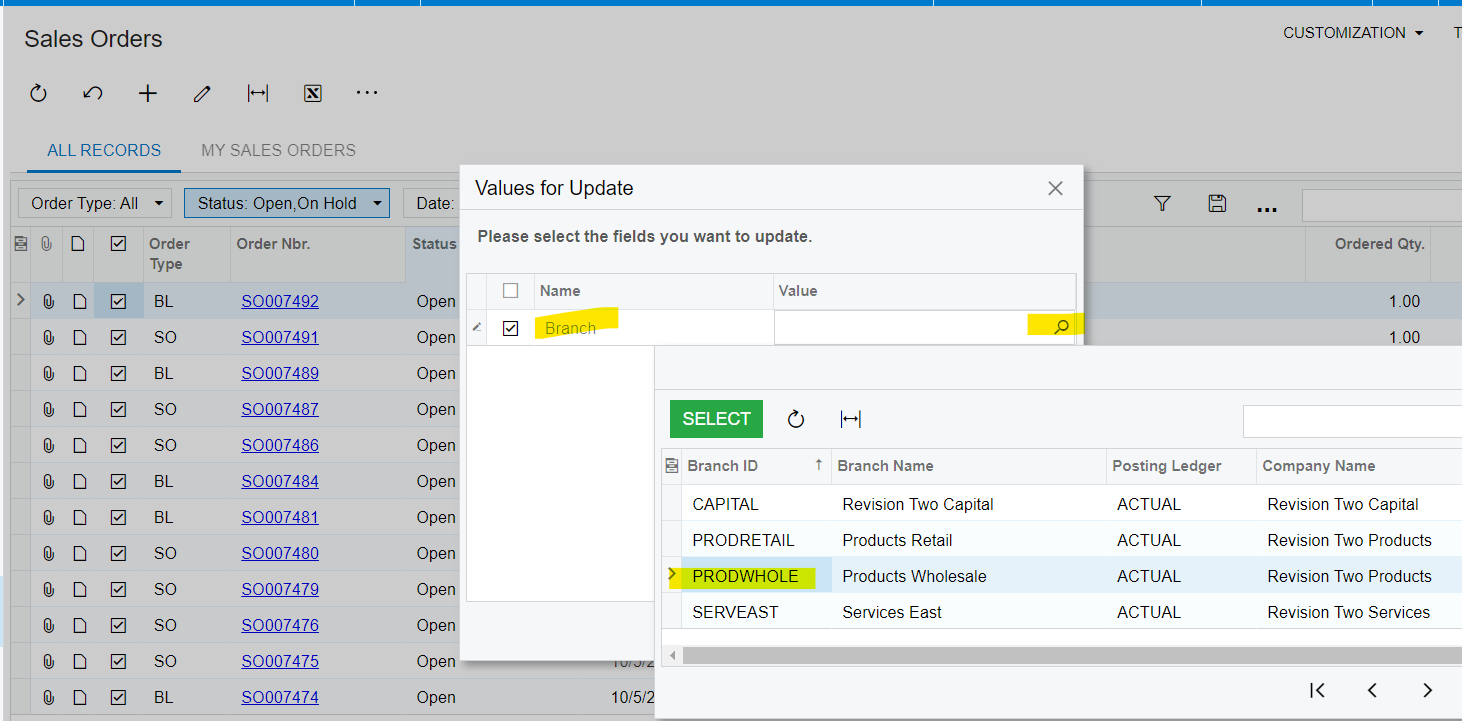

Sample from Sales Order Screen:

- Select the values to update

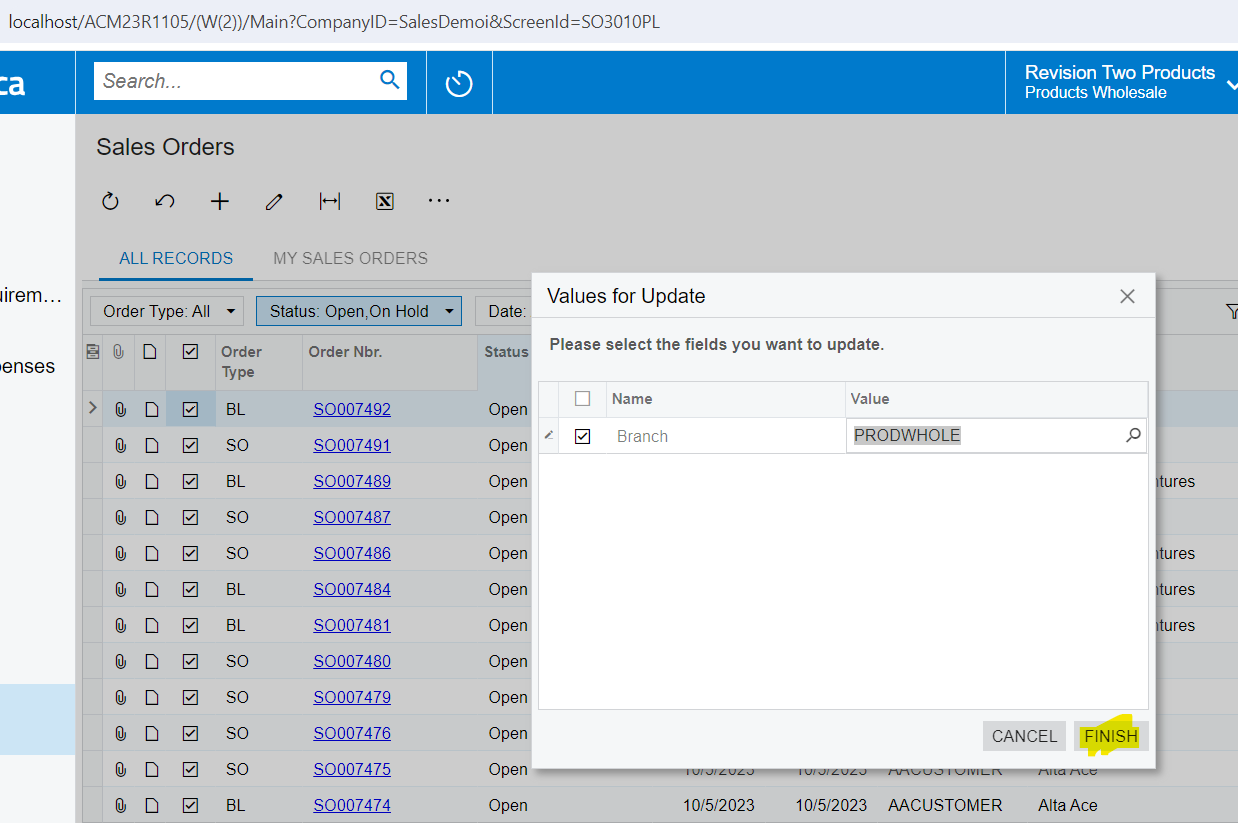

- .Finish. This should update the required field on the screen assocated with the Generic Inquiry

- .Finish. This should update the required field on the screen assocated with the Generic Inquiry

- View Inquiry on the generic Inquiry to see how it works::

Thank you Chandra, I will try this.

A GI will not work as I am sure you have confirmed.

Create a GI with AMBOMOper joined to AMBOMItem. The fields you need are the BOMID, Revision, Operation ID, and the columns on the operation you want to update.

Create an import scenario.

BOMID

Revision

Operation ID

(columns to update)

Save

No need to place the bill of material on hold.

Thank you, dgodsill97 that is what we are working on. This simple change has been escalated to become part of a project to be used with our ECO process. So, we are working on an export\import process, which will be using an import scenario, to be able to update any part of the BOM that needs to be mass changed.

Great. It is a bit more complicated to update material lines because you need to use a search command (@@InventoryID) in the import to find the material on the operation.

Here is the export scenario I use to export BOMs and the Import Scenario I use to Update BOMs.

Note that this Import scenario is set up to either Add, Delete, or Modify material lines. When preparing to run the import It’s important to make sure the appropriate lines are set as “Active” to accomplish the task at hand.

Obviously if you need to set it up on a schedule, you would probably want to create separate Import scenarios for each operation. However, since I’m always manually triggering it, it’s easier to have one Import scenario that can do various update operations just by changing the active lines on the scenario.

These scenarios are working in the 2023R2 Acumatica release.

You could also consider CADTalk.

Reply

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.