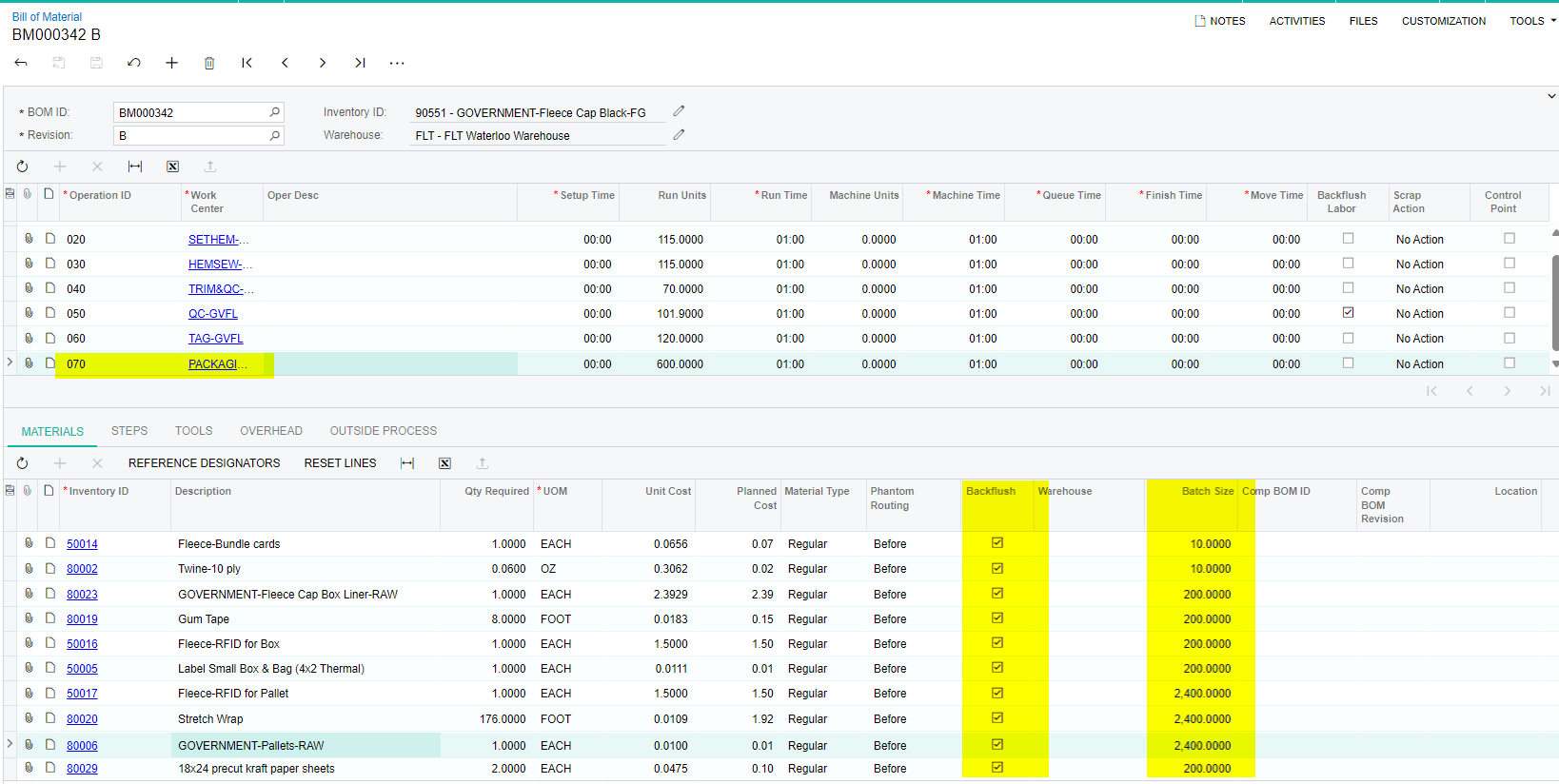

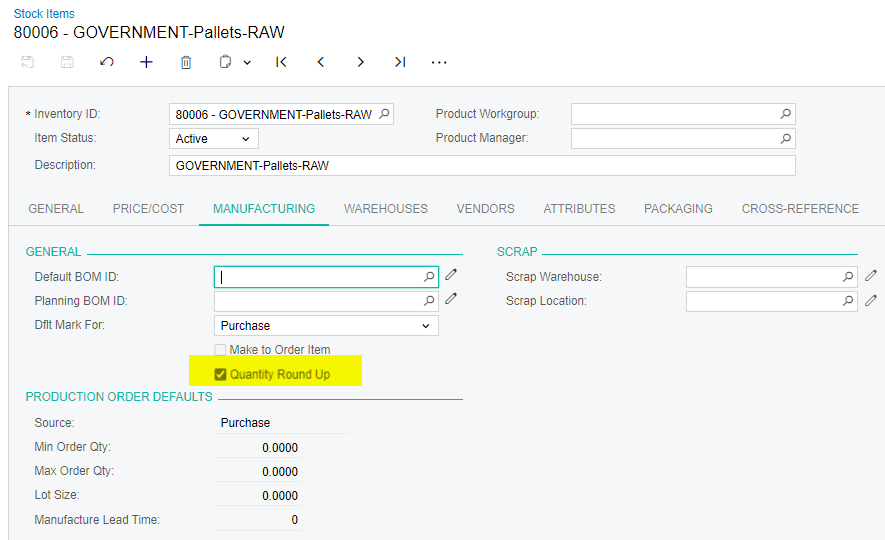

My client has a manufacturing order that use batch sizes for materials. i.e. 200 items per box, 1 box tag per box and 2400 items per pallet, 1 pallet tag per pallet. They are all set to backflush. The MO looks correct, but the client states that it keeps backflushing too many pallets etc and they have to continually add additional and count the inventory.

In digging into this, it looks as if every line of a labor entry for a date creates the backflush issue of the pallet, tag, etc. If there are 3 lines on a labor/clock transaction with quantities, it backflushes 3 times -3 pallets and 3 boxes -so too many pallets and not enough boxes.

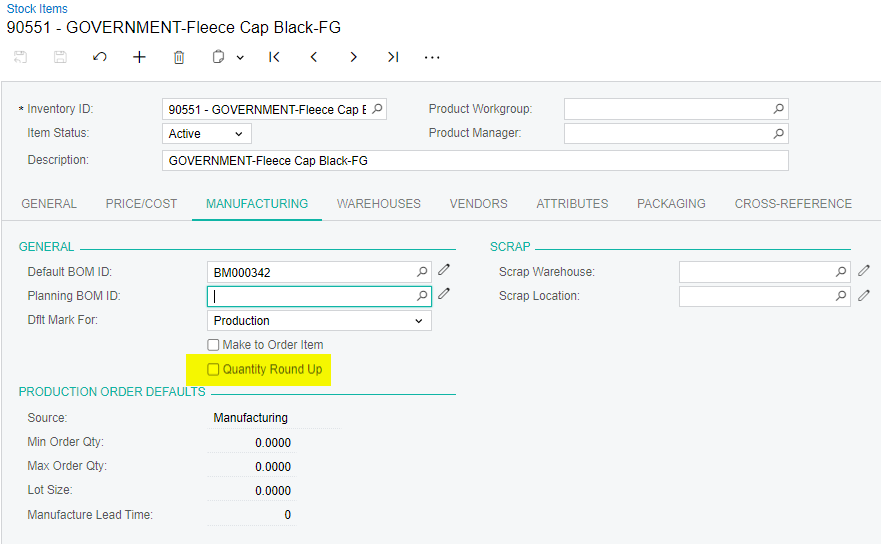

I am getting confused in reading through the help menu on how batch sizes are used. It seems that the finished good should perhaps have data populated on the stock item IN202500 manufacturing tab for min/max order qty and lot size? I have been brought in recently on this client and am not familiar with this.

How do I get this set up correctly to recognize the batch sizes when backflushing instead of backflushing every time goods are marked complete?