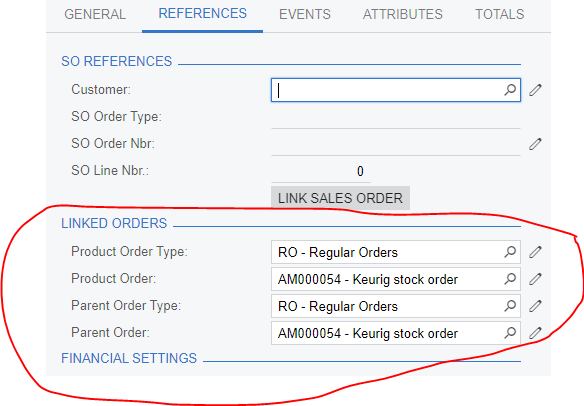

Our client currently treats all Subassemblies as one Production Order, yet going forward they want to have more visibility and scheduling capabilities for each Subprocess and Assembly.

So we run into the challenge of Data Conversion for open Production Orders right now & on how to convert one Parent Job to multiple Subassemblies in a clean way.

Basically, Product X contains Subassembly A, B, C and D. Potentially Subassembly A consists of Subassembly E and F.

This is currently treated as one Make-to-Order Production order.

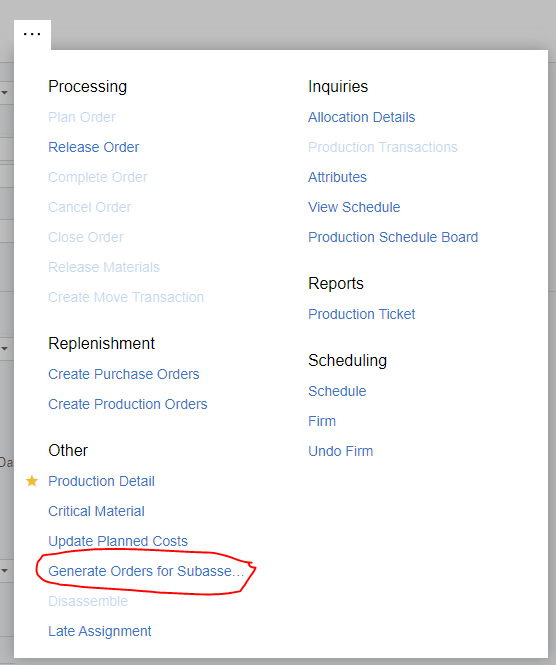

Going forward they want to have multiple Jobs for A,B,C,D,E and F that roll up into the final Assembly Job of Product X. (Product X and all Subassemblies have Bill of Materials behind them).

Has anyone encountered a similar case within the implementation?

We have some ideas with their Pros and Cons but want to see what is already proven or if other ideas are out there.