Hi All,

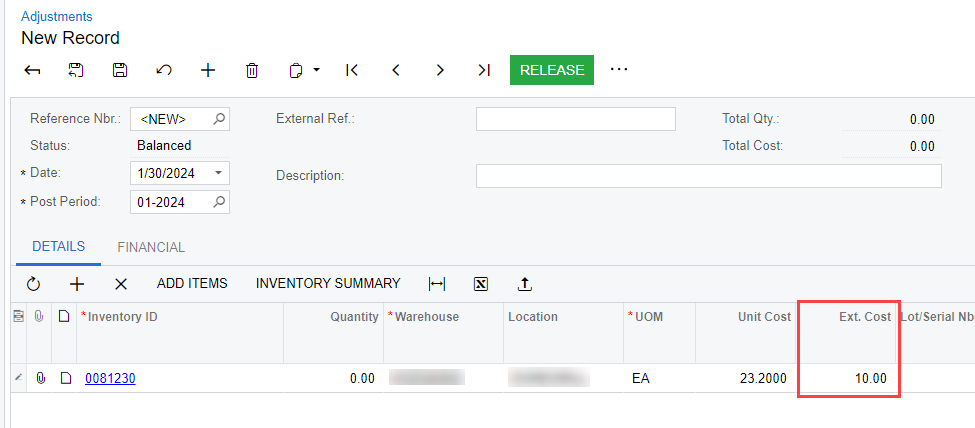

I have manufactured parts that are already in stock and ready to be sold. I am sending them out for a finishing process so I’m not going to be running them thru production as I don’t need to have “extra inventory.” Does anyone know a way to get this outside processing cost onto the cost of the part without doing a landed cost?