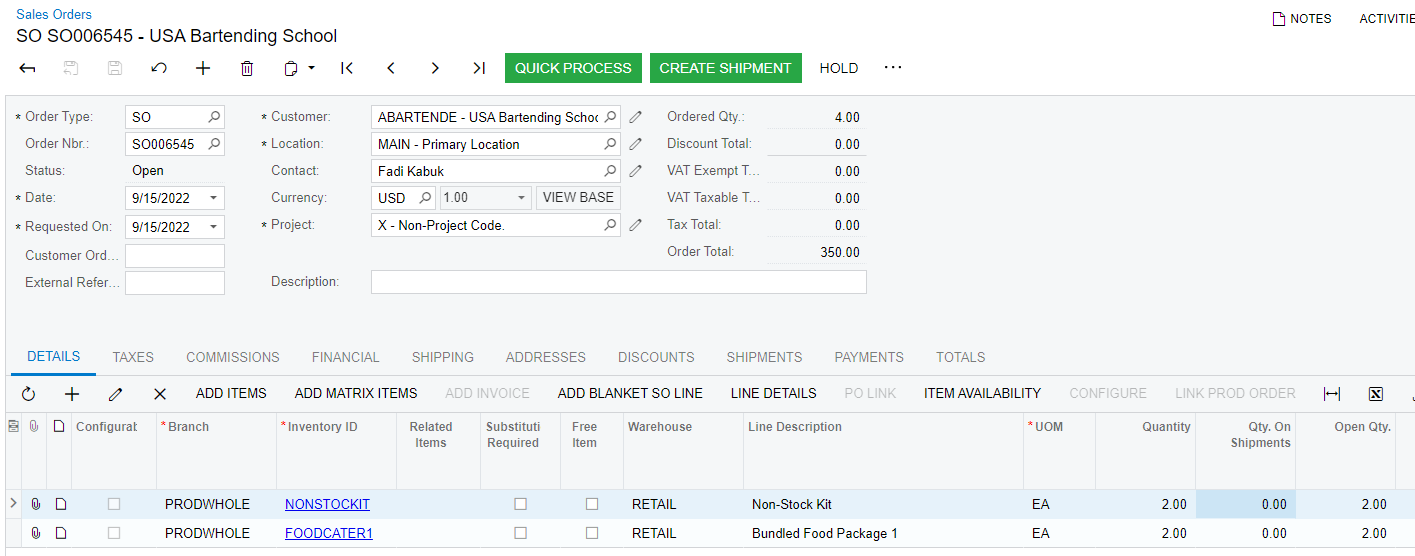

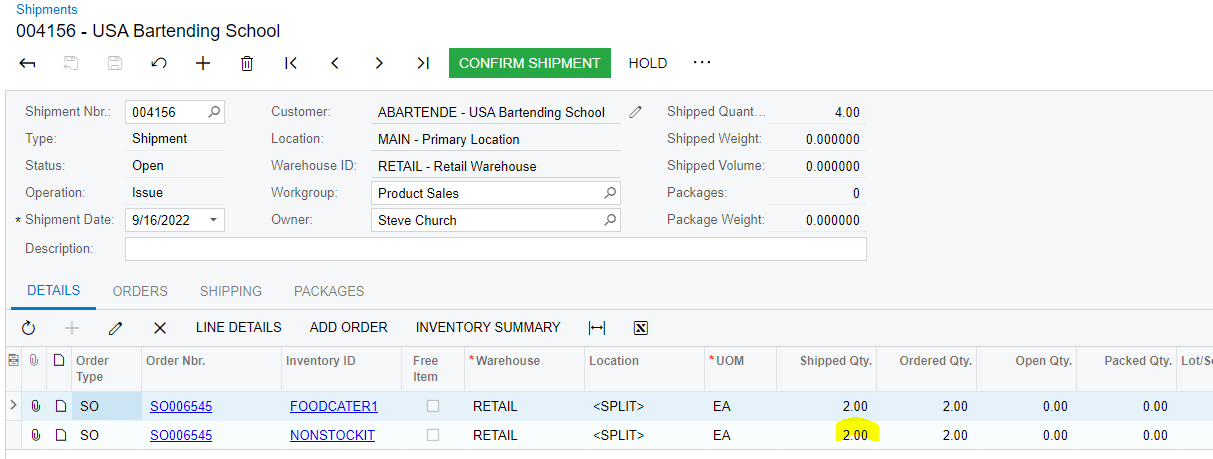

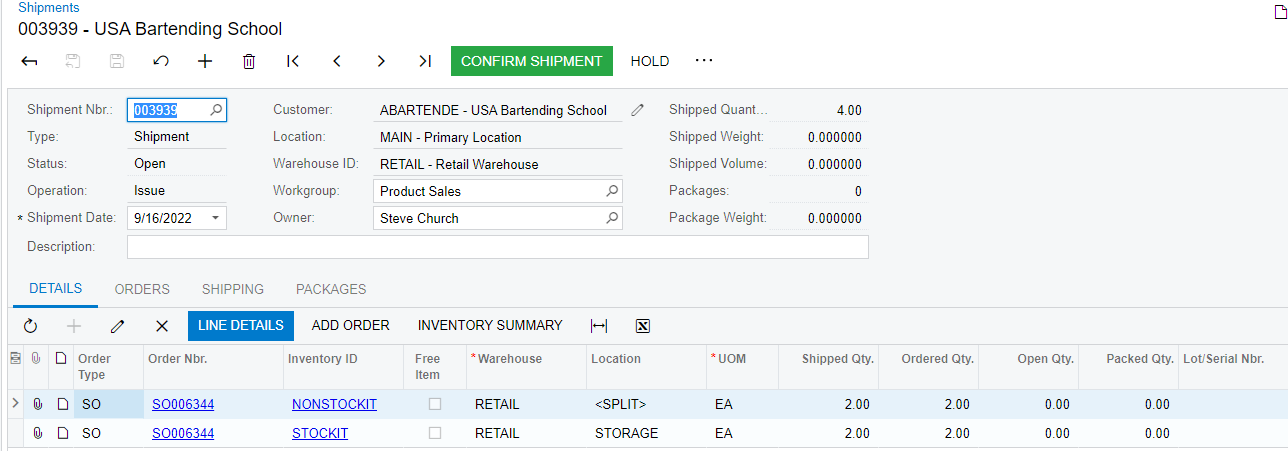

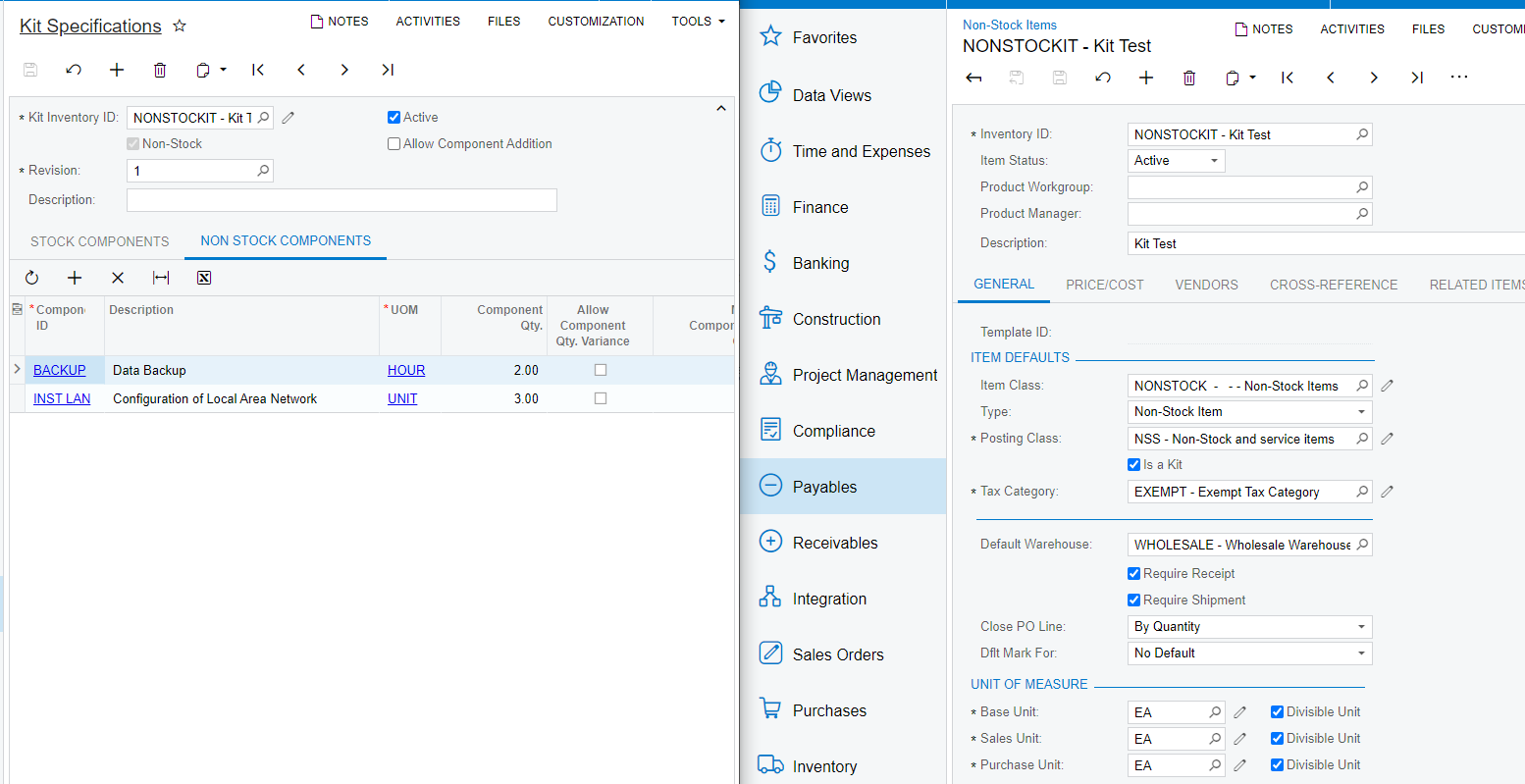

I’ve found that the non-stock kits default in a qty 0 shipped qty on the shipment. The allocation of the kit items do not occur until the shipped qty is manually updated. At that point, the items display on the pick list. Does anyone know why normal items bring over the shipped qty from the order while non-stock kits require inputting in a qty before the kit components allocate and show on the pick list? In order for the components to display, this flow is requiring users to manually updated the shipped qty on the non-stock kit item to get the components to allocate and display on the pick list.

Solved

Non-stock kits don't allocate components until the shipped qty is manually updated on shipment?

Best answer by hayleehicks

Reply

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.