Hello,

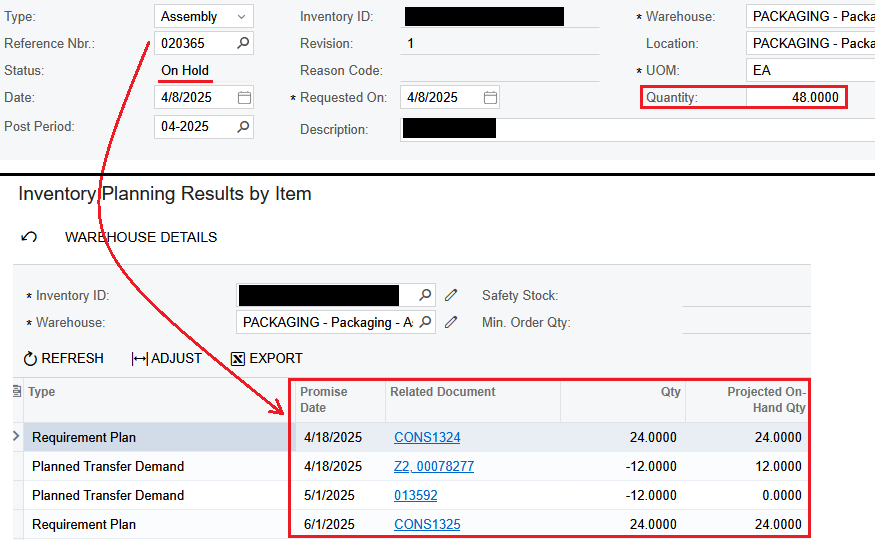

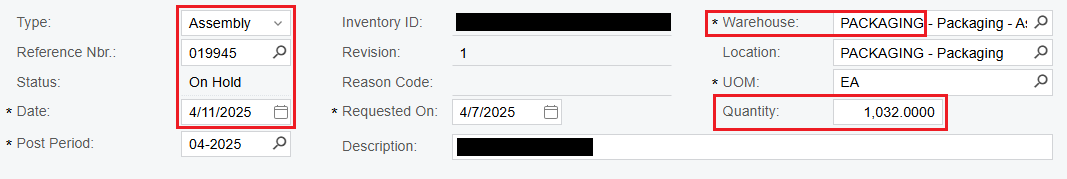

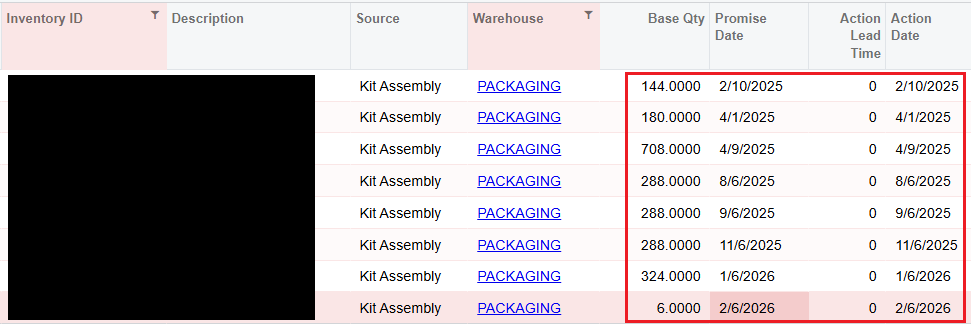

I have a customer who is using DRP and Kit Assembly to plan out what needs to be assembled for Sales Orders that drop in each week. One example is the Kit Assembly pictured below:

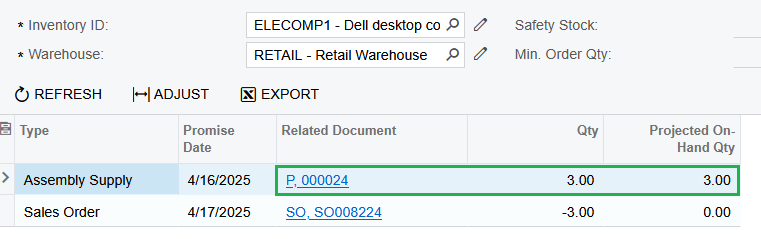

Even though this Kit Assembly has been created, DRP is not considering it in the Inventory Planning calculations. The customer is understandably concerned because they don’t want to create unneeded inventory by creating new Kit Assemblies every day, as Inventory Planning Display is suggesting:

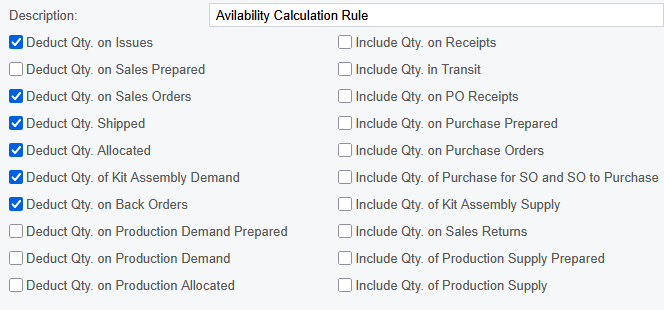

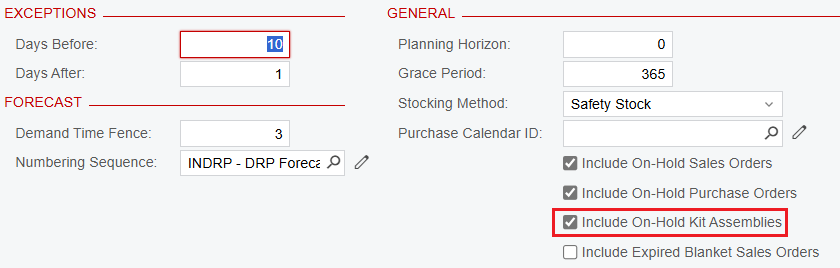

The Kit Assembly is On Hold, but that is taken care of in Inventory Planning Preferences:

I have exhausted what I suspect could be the issue including the following:

- Kit Assembly and Distribution Requirements Planning are both enabled on the Enable/Disable Features (CS100000) form

- The Stock Item has the “Is a kit” box checked

- The Kit Specification is Active

- The General tab on the Stock Item has a Planning Method of DRP

- The Inventory Planning tab on the Stock Item has “Kit Assembly” as the Source

- The PACKAGING Warehouse in Item/Warehouse Details has the following settings:

- Planning Method: DRP

- Source: Kit Assembly

- The PACKAGING Warehouse has all of the Inventory Planning settings checked

I don’t know what else may be ‘blocking’ the Assembly Supply from being considered in the Inventory Planning Regeneration process.

Thanks in advance for any help on this!