We have individual SKUs that ship in more than one box. In the Acumatica pick, pack, and ship process, the Acumatica workflow seems only to accommodate one box / one shipping label per SKU. How can we print multiple shipping labels for a multiple-box SKU? We do not have Acumatica WMS. Your help is greatly appreciated.

Solved

How to ship a multiple box SKU in Acumatica shipping

Best answer by MattNelsen

Do the SKUs in question ship in multiples of the same box, or are they different sized boxes?

Let me preface by saying we don’t currently use the Pick, Pack, Ship functionality as we found it cumbersome with no value-add, but we have had some success with two scenarios via the standard Shipment processing:

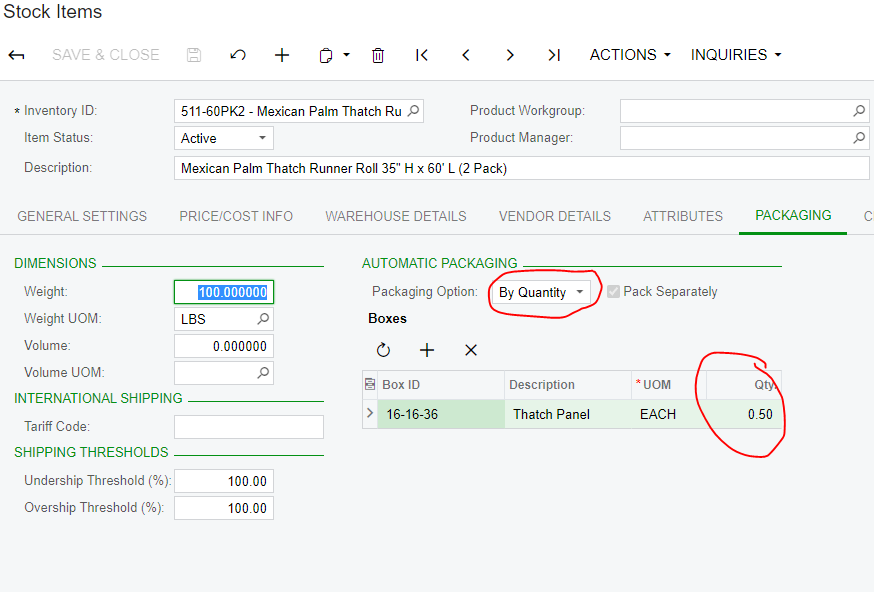

- Items that ship in multiples of the same box can have a decimal number in the packaging section, forcing the sold item to be packed into multiple boxes. For example, a 2-pack item would be packed .5 per box; see below example. The caveat would be items with non-terminating decimals (eg 3-pack, 6-pack etc), in how it would factor remainders.

- If they are different box sizes (or if you want to avoid the decimal problem), you could try carrying the boxes as unique Stock Items, and use a Non-Stock Kit to sell them together.

Both of these scenarios can cause problems with ASNs though, although I think you’d have an easier time fixing the second than the first.

Hope this helps!

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.