We have stock items that are now discontinued, but we still have inventory in our other warehouses. Is is possible to prevent sales in one warehouse but still allow in another?

Solved

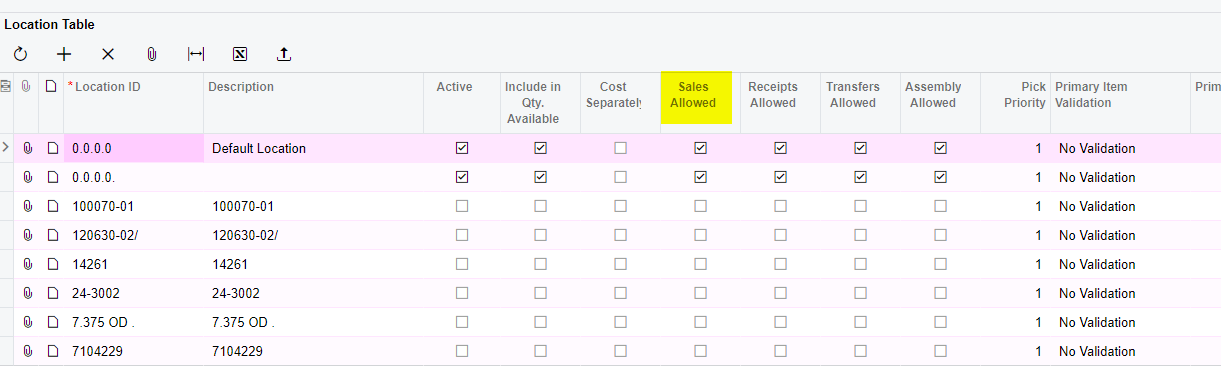

Discontinued Stock Item, allow sales from specific warehouses

Best answer by jharris

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.