Hi,

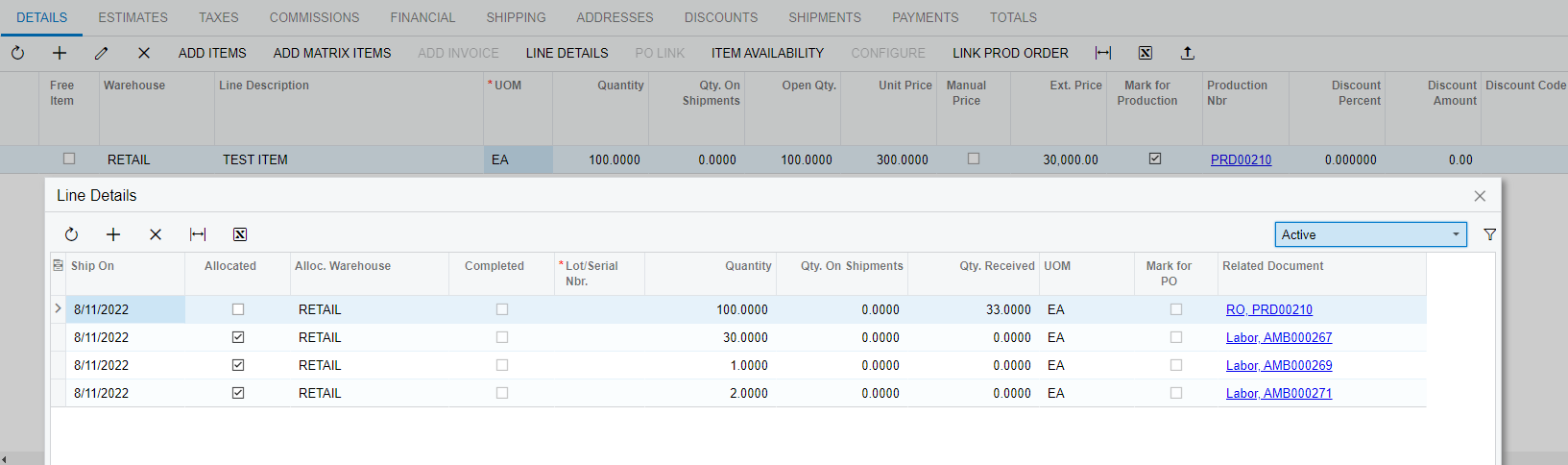

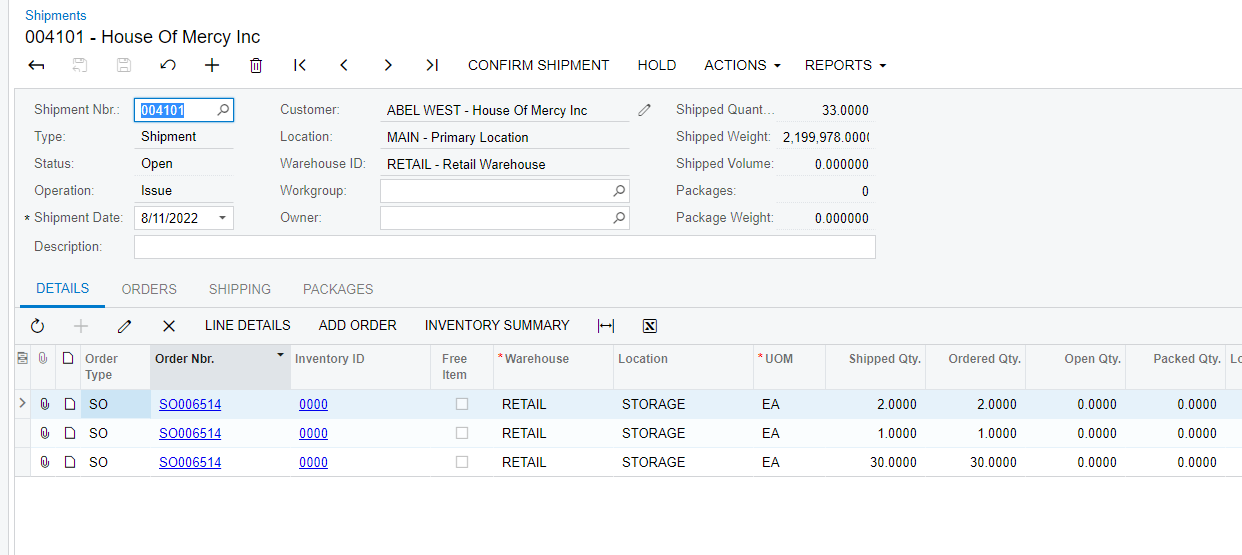

Have noticed that when it comes to shipping our manufactured items, the Shipment document will split one shipped item ID into multiple lines, which corresponds to one for each quantity we produced under Move/Labor under Manufacturing.

I presume this is because an allocation is created for each Move/Labor document, as opposed to the gross produced quantity as a whole.

Needless to say, this can get rather messy when shipping, if for example we manufacture 1 units per day for 60 days. When we ship the 60 units, we end up with a long Shipment document of 60 lines of the identical item with 1 qty each and a puzzled freight carrier.

Is there any way of consolidating the Shipment document to present this as one shipment line based solely on the Inventory ID?

Thanks in advance!