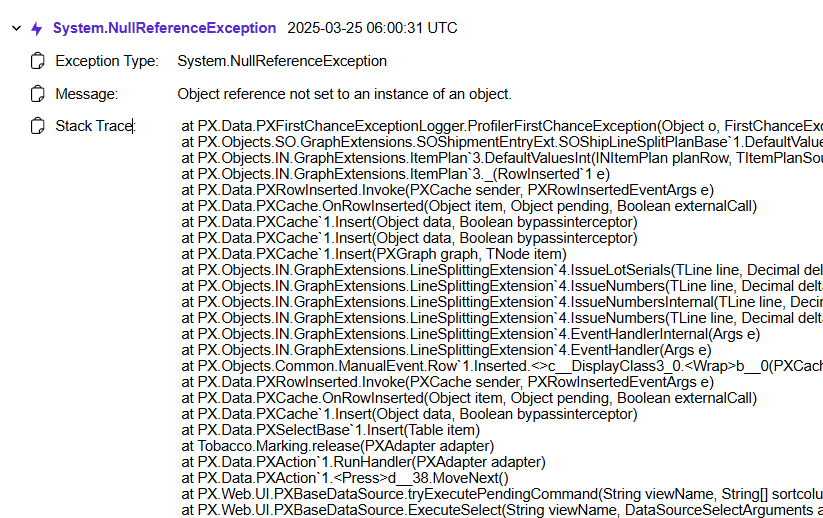

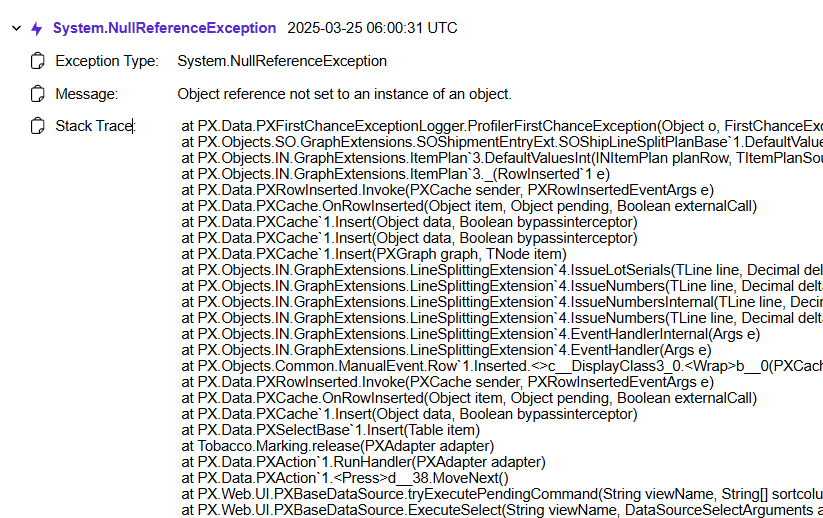

I am Get erorr "Object reference not set to an instance of an object" when trying insert shipment,

Why Like This ?

This the problem track

Please Help me Sense

Thanks you

I am Get erorr "Object reference not set to an instance of an object" when trying insert shipment,

Why Like This ?

This the problem track

Please Help me Sense

Thanks you

Best answer by harutyungevorgyan

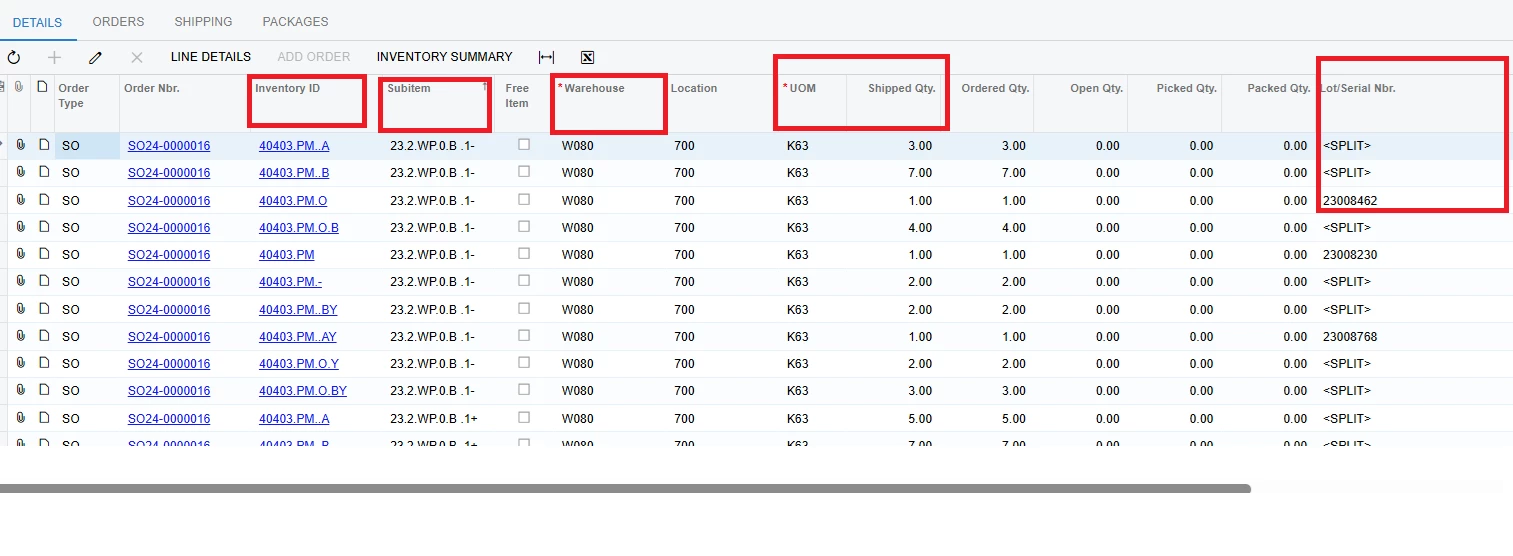

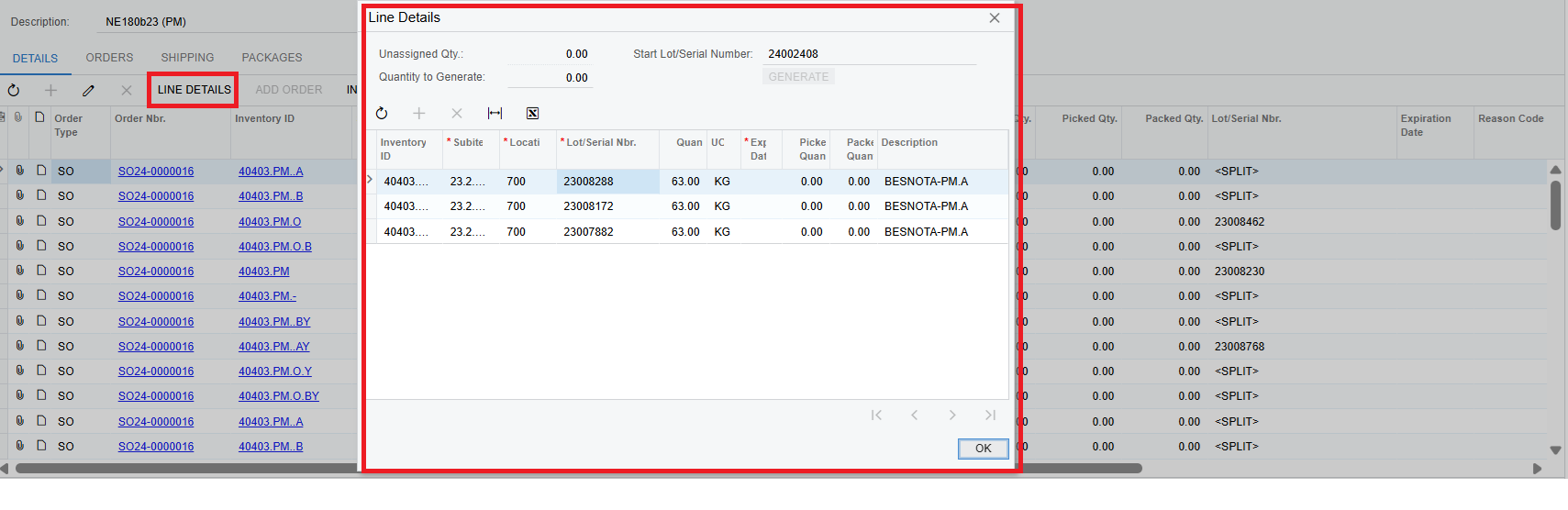

Can this method include lot number field ?

or if the goods have the same inventory, subitem, warehouse and location but the lot number is different, the details must be entered in Line Details ?

please help me

Hi

The method I gave you uses OrderLineNbr, which means the system will automatically pull the data from the SOOrderLine into your shipment line.

However, when it comes to Line Details (commonly referred to as line splitting or allocation), that logic needs to be handled separately. If you want to control splits manually, you’ll need to explicitly add the required allocations yourself. To do this correctly, I strongly recommend first understanding how the allocation process works—especially its impact on Qty. On Hand, Qty. Available, and related inventory quantities. Also, make sure that the lot/serial number you’re trying to use is available in the exact warehouse and location you're assigning it to.

At this point, the discussion is moving into more advanced customization, and it’s no longer related to the original error you reported. If the issue with adding lines from the Sales Order is now resolved, I’d suggest closing this topic. You can open a new thread specifically focused on handling splits or allocation logic when you're ready to explore that further.

Hope this helps!

Reply

Enter your E-mail address. We'll send you an e-mail with instructions to reset your password.